Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Construction of New Railway Lines and Track Linking

Construction of New Railway Lines

Introduction

The construction of a new railway

line in an area is normally required for one or more of the following reasons.

(a) Strategic

and political considerations

(b) Development

of backward areas

(c) Connecting

new trade centres

(d) Shortening

existing rail lines

Existing single railway lines are

also doubled in a few cases to cope with the burden of additional traffic.

Recently, a large number of projects have been undertaken for converting

existing metre gauge lines into broad gauge lines in order to ensure a uniform

gauge for the smooth flow of traffic.

Construction of New Lines

The main tasks involved in the construction of a new line are

as follows.

(a) Land

acquisition

(b) Earthwork

and bridges

(c) Construction

of station building, staff quarters, and other allied facilities, including

platforms and sheds

(d) Laying of

plates including ballasting of track

(e) Opening

of section to traffic

1 Land Acquisition

The work of land acquisition

should start well in advance so that all the legal and financial formalities

are completed in time and the possession of the land is taken for starting

construction work. Land acquisition is done with the help of the State

Government as per the procedure laid down in the Land Acquisition Act.

Normally Sections 4 and 6 of the

Land Acquisition Act are applied for the acquisition of land. Whenever land is

to be acquired, it is generally done after giving a certain notice and paying

the requisite compensation. In the case of an emergency, land can also be

acquired urgently by the application of Special Sections 9 and 17 of the Land

Acquisition Act.

The land being acquired should be

sufficient for the formation, berm, and borrow pits. It should also have

adequate provision for any future expansion. Even when a single line is to be

constructed, it should be ascertained that the land made available is suitable

for future conversion into a double line. Normally a strip of 15 to 25 m of

land is acquired for the construction of a railway line. An extra width of land

is acquired for station yards. In the case of small stations, the width

normally adopted is 150 × 1000 m.

The minimum measurements of the

selected land should be such that it can cater to the following requirement.

Width of formation The land

should be adequate so as to accommodate the width of the formation.

Side slope This

depends on the nature of the soil and is normally taken as 2:1 (horizontal:vertical).

Width of berm

The width of the berm is usually kept as 3 m.

Borrow pits If the

land is not very costly, adequate land should also be made available for

borrow pits. Borrow pits may be provided on one side of the track for low banks

and on both sides of the track for medium and high banks.

When the land is expensive,

borrow pits need not be provided and instead earth can be borrowed from

adjoining areas. Extra land is, however, required for station yards, level

crossings, and bridge approaches.

2 Earthwork for Formation

Depending upon the rail level and

general contour of the area, the formation may be laid in an embankment or in a

cutting. A formation laid in an embankment is normally preferred because it

affords good drainage. The height of the embankment also depends on the high

flood level (HFL) of the area and a reasonable free board should be given above

the HFL.

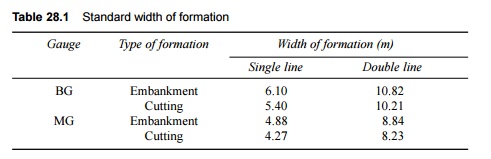

The

standard widths of the formation for BG and MG lines are given in Table 28.1

Table 28.1 Standard width of

formation

Some of

the points to be kept in mind with regard to earthwork are given below.

(a) Earthwork

is normally done in 30-cm layers so that the soil is well compacted.

(b) Mechanical

compaction is normally done after each layer of earthwork with the help of a

sheep foot roller to obtain 90% maximum dry density at an optimum moisture

content.

(c) A

shrinkage allowance of 5% is made for the consolidation of the final cross

section in the case of mechanical compaction. The shrinkage allowance is

increased to 10% if no mechanical compaction is involved.

(d) A blanket

of a thickness of about 30 cm is provided at the top of the embankment where

the soil is not of good quality.

(e) In areas

where there are both cuttings and embankments, the soil from the cuttings

should be used for the embankments up to an economical lead. The economical

limit of moving the earth in the longitudinal direction is determined by the mass-haul

curve.

(f) For the

early execution of earthwork, the section is normally divided into convenient

zones, with each zone requiring earthwork costing Rs 1.5 to 3 million

approximately. Tenders are separately invited for each zone so that work can

progress simultaneously in all the zones.

3. Bridges

Bridges should be designed to bear the load of the heaviest

locomotive likely to pass the section. Depending upon the topography of the

location and the type of stream to be crossed, hume pipe culverts, RCC slab

bridges, plate girders, PRC girder bridges, or steel bridges are designed.

Bridges, being important structures, are normally constructed to accommodate a

double line even in those sections where only a single line is being set up so

that future expansions can be planned.

Separate tenders are invited for the construction

of important bridges so that the bridge design and construction can also be

included in the tender documents. Minor bridges and culverts are normally

included in the earthwork zones mentioned earlier.

4

Service Buildings and Staff Quarters

Service buildings include buildings such as the station

master's office or telegraph office, which are basically required for providing

assistance in the running of trains. Apart from this, staff quarters and other

passenger amenities such as platforms, foot over bridges, waiting halls, and

retiring rooms are also provided at the stations. Many other ancillary

facilities such as water, drainage, telephone lines, and electricity are also

made available at every station.

All these constructions are taken up

simultaneously by civil engineers, electrical engineers, and signal engineers

so that all work can progress together.

5 Plate Laying or Track Linking

Once the formation is ready, plate laying or track linking

should be done, which basically consists of laying rails, sleepers, and

fastenings. The following methods can be adopted for plate laying.

Tram line method

In this method, a temporary line

known as a tram line is laid by the side of the proposed track for

transporting track material to the site. This method can be useful in flat

terrains, where laying of a tram line on the natural ground may be

comparatively easier. This method is, however, seldom used in actual practice.

A modification of the above

method, called side method, is also in practice, where track and bridge

material such as steel girders and RCC slabs is carried to the site in trucks

on a service road that runs parallel to the track. These materials are then

unloaded near the work site. This method is used only in cases where the

terrain is comparatively flat.

American method

In this method, rails and

sleepers are first assembled in the base depot, and the pre-assembled track

panels are then conveyed to the site along with the necessary cranes, etc. The

track panels are then unloaded at the site of work either manually or with the

help of cranes and laid in their final position.

This procedure is used in many

developed countries, particularly where concrete sleepers are laid, which are

quite heavy and not very easy to handle manually.

Telescopic method

This method is widely used on

Indian Railways. In this method, the rails, sleepers, and other fittings are

taken to the base depot and unloaded. The track material is then taken to the

rail head, where the tracks linked and packed. The rail head is then advanced

up to the point where the track has been laid. The track materials are then

taken up to the extended rail head with the help of a dip lorry and the track

is linked and packed again. Thus the rail head goes on advancing till the

entire track has been linked. The main operations involved in this method are

as follows.

Unloading of materials The track

materials are taken to the base depot and unloaded with the help of

material gangs. The first base depot lies at the junction of the existing line

and the new line to be constructed. All the track material is taken from the

base depot to the rail head with the help of a dip lorry (a special type of

trolley). The rail head goes on advancing till the track is sufficiently

linked. After that, a subsidiary depot is established at a distance of about 5

km and track material carried to this depot with the help of a material train.

Alternatively, track material is transferred from the base depot with the help

of a dip lorry up to a distance of about 2 km and by the means of a material

train beyond this distance. The base depot has arrangements for advanced

processes such as adzing and boring of sleepers as well as for matching

materials, etc. to ensure the speedy linking of the track at the site.

Linking of track Once the

track material is unloaded, the track is linked with the help of linking

gangs. The following procedure is normally adopted for this purpose.

1.A string is first stretched along the central line of the

alignment and the sleepers are laid with their centres on the string. The

sleepers are laid roughly at the desired spacing, keeping the total number of

sleepers per rail intact.

2.The rails are carried using rail tongs and laid on the cess

of the bank almost near the final position. Carrying rails is a strenuous job,

as about 12 to 15 gangmen are required to carry each rail (each rail weighs

about 0.6 t or so). A special type of rail carrier known as the Anderson rail

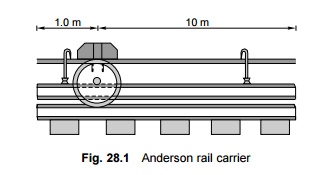

carrier, shown in Fig. 28.1, can be used for carrying rails with lesser strain.

3. Next the

sleepers are distributed over the length of the formation. The rails have

markings to indicate the final position of the sleepers as shown in Fig. 28.1.

4. Small

fittings such as fish plates and bolts are kept near the joints. The fittings

required for each sleeper are kept near the ends of the sleepers.

5. The rails

are then placed on the sleepers and fixed with the help of fittings, which are

chosen depending upon the type of sleeper. For example, rail screws are used

for fixing rails to wooden sleepers. In the case of steel sleepers, rails are

fixed with the help of keys. Bearing plates are also provided wherever

required, as per the prescribed track standards.

6. The rails

are joined with each other after ensuring that there is sufficient gap between

them. Normally, the initial laying of the tracks is done using three rail

panels. Adequate expansion gaps should be provided in the case of single-rail

as well as three-rail panels. The recommended expansion gaps are provided with

the help of steel liners or shims of appropriate thickness (1 mm to 4 mm),

which are fixed between the two rail ends.

Packing of track The track

is then thoroughly packed with the help of beaters by the

Packing-in-gangs. The following aspects should be examined during this process.

(a) The track

should have a proper gradient.

(b) If the

track is on a curve, it should have proper curvature.

(c) The cross

levels should be even. If a track is to be provided with the recommended

superelevation, this can be achieved by raising the outer rail.

(d) The track

should be thoroughly packed and should be free of hollow spaces.

Ballasting of track The

railway line is normally covered with the ballast after the embankment

has settled and has endured at least two monsoons. Ballasting is generally done

with the help of a ballast train, which has special hoppers that are used for

automatically unloading the ballast onto the track. Alternatively, the ballast is

taken to the cess and then placed on the track manually. Either method ensures

that the ballast is thoroughly packed and inserted properly under the track.

Related Topics