Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Construction of New Railway Lines and Track Linking

Gauge Conversion

Gauge Conversion

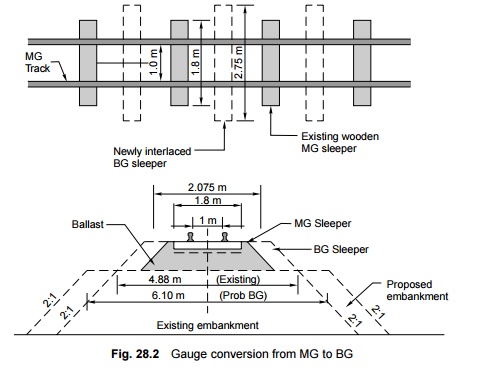

A number of projects have

recently been taken up by Indian Railways for converting railway lines from

meter gauge to broad gauge. Gauge conversion projects (Fig. 28.2)

basically aim at providing a uniform gauge for the smooth and fast flow of

traffic, which may be necessitated either due to strategic reasons or on

account of operating considerations.

The main advantages of gauge

conversion as well as its details are discussed in Chapter 2.

1 Execution of Gauge Conversion Projects

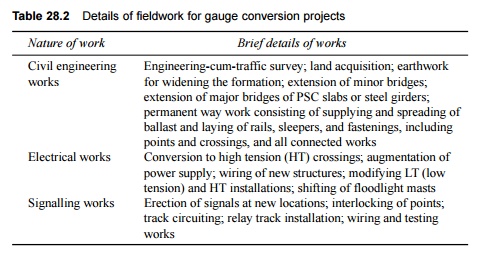

Details of works The

fieldwork normally involved in gauge conversion projects is presented in

Table 28.2.

Planning of works Gauge

conversion projects require detailed planning as they involve expansion,

which needs to be carried out in a tight time schedule and multifarious

activities such as assigning of contracts; posting and management of manpower,

including supervisors and artisans, etc.; supply of track materials; and

coordination between the engineering, service and telegraph, electrical,

operating, and various other departments. Most of the engineering work is done

by placing traffic blocks on a regular basis while the residual work is finally

completed after placing an extended traffic block of several consecutive days

on the route, during which time gauge conversion works are executed on a war

footing.

Manpower requirement The

manpower required for the various tasks involved in a gauge conversion

project is to the tune of about 80 labourers per km to ensure that gauge

conversion is completed within 30 days in all respects. One PWI and one AEN

should be assigned for one- and two-block sections, respectively, for the

continuous monitoring of the progressing work to ensure the requisite quality

control. The contractor should also engage at least two competent supervisors

per block section in addition to the trained permanent way mates appointed for

each gang.

Speed potential Two

rounds of packing by light off-track tampers such as phooltas or chinese

tampers are required to make the track fit for a speed of 50 km/h. This is

further supplemented by two more rounds of packing using heavy on-track tie

tamping machines for making the track fit for a speed of 100 km/h.

Economy measures Gauge

conversion projects are capital intensive and adequate financial

resources have to be mobilized to meet these ambitious targets. The Railway Ministry

has, therefore, taken a decision that all schemes of gauge conversion are to be

carried out in the most economical way. By cutting down the cost of gauge

conversion in various ways, the Railways plan to carry out gauge conversion

works at an economical cost of Rs 6 to 7 million per km as against the normal

cost of Rs 9 to 10 million per km, thereby saving about 30 to 40% on the

initial cost. The guidelines to be followed in this regard are the following.

(a) The

maximum permissible speed on the converted BG section need not be more than

what was previously specified for the MG section.

(b) The

facilities required at the stations should not be more than what has already

been provided except that the loop length should be 686 m.

(c) The

length of the platform at those stations that currently serve as stops for

mail/express trains should be just enough for accommodating l6 coaches. If the

existing platform needs to be extended, the extended portion should be

constructed at rail level. On suburban sections, the length of the platform

should be enough for 12 coaches. At important stations, the platform length

should be sufficient for no more than 22 coaches with added provisions for

future expansion to include 26 coaches.

2 Civil Engineering Works of Gauge Conversion

Projects

Engineering-cum-traffic surveys The

survey is done to examine the technical feasibility of the proposal and

the economical aspects of the same.

Land acquisition The land

requirement for converting the track from MG to BG is assessed and, if

necessary, extra land is acquired as per the existing procedure laid down in

the Land Acquisition Act.

Earthwork Earthwork is done on either side

of the existing formation of a single-line track to increase its width from

4.88 m (16 ft) to 6.10 m (20 ft) in the case of embankments and from 4.27 m (14

ft) to 5.49 m in the case of cuttings.

Bridges and culverts The

existing bridges and culverts are extended to suit the BG formation and

to conform to the standards adopted for BG sections. The extension of these

bridges is properly planned to ensure the minimum dislocation of traffic.

Track linking

Track linking involves the following operations.

Unloading of track material Track

material such as rails, sleepers, and fastenings are taken from

the base depot to the work site and unloaded at the final location. Preliminary

works such as boring and adzing of sleepers, proper matching of rails, and

drilling of holes in the rails are planned in advance.

Interlacing of sleepers Wooden

sleepers are best suited for gauge conversion projects, if

available. They are interlaced with the existing sleepers of the track and the

two are spiked together.

Arrangements of men and materials The

deployment of manpower, including the supervising staff, is

planned in detail so that the conversion of the track from MG to BG is achieved

with minimum interruption of traffic. Normally 50 to 100 men per km work are

required on the track during a traffic block. In addition, the work of skilled

artisans such as blacksmiths is also required for track conversion. All track

material, including fittings, are properly organized and arranged at the site.

Tools and equipment such as augers and drills, Jim Crows, crowbars, rail tongs,

sleeper tongs, and spanners are also arranged in adequate quantities.

Traffic blocks Traffic

is suspended on the railway line for a period of 15 to 30 days depending

upon the length of the track to be dealt with, so that the work of gauge

conversion can be carried out at one stretch. During a traffic block, traffic

is diverted on alternate routes or trans-shipped onto road vehicles.

Linking the new track During

the traffic block, the existing rails are removed and new rails

placed in what is to be their final position on the BG track. The new sleepers

are also placed in their proper position and the rails are spiked to the

sleepers as per BG requirements. The track is properly levelled and aligned and

traffic is allowed on the new line at a restricted speed after obtaining the

sanction of the commissioner of railway safety.

Ballasting and packing An

adequate quantity of ballast is then put in the track and the

track is properly packed. The speed restrictions are gradually relaxed as the

stability of the track improves.

Related Topics