Chapter: 11th Textiles and Dress Designing : Chapter 4 : Yarn Production

Yarn Manufacturing Process

YARN MANUFACTURING PROCESS

Fibres are twisted together to form a yarn. This

process is called as spinning. Spinning pro-cess includes all process from

cleaning the fibres to opening the bale for twisting of yarn.

Opening and Picking

The fibres are collected from various bales which

are mixed together and finally the yarn is produced. Simultaneously,

impuri-ties such as lint, dirt, seeds, leaves and stems are removed by the

machines (picker, break-ers and intermediates). After cleaning, the fibres are

loosen end and formed like a lap.

Carding

Lap is unrolled and drawn into a revolv-ing

cylinder, which contains fine hooks or wide bristles. These will pull the

fibres in one direction and form them into a thin film. It is known as carding.

This film is drawn into a funnel shaped opening. The yarn comes out in the form

of round rope like strand called sliver (Figure 4.3).

Combing

It is a process of straightening the fibre. Short

fibres are combed out. The long fibres are again formed into a sliver called

comb sliver (Figure 4.4).

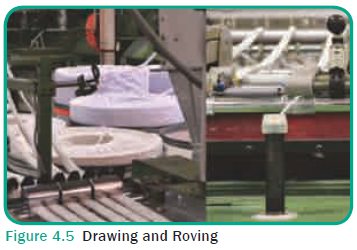

Drawing

In drawing process, several slivers are drawn

together. Slivers are drawn to form a single sliver of the same diameter (Figure

4.5).

Roving

The combined sliver or condensed com-bined sliver

is taken to the slubber of a series of machines called Roving frames. A slack

twist is given to the yarn sliver (Figure 4.5).

Spinning

Spinning is the next process after roving.

Spinning frame is made up with a number of spools. The roving passes through

the ring spinning mechanism, which is drawn again and twisted. Required size

and twist of yarn is obtained and wound on bobbins properly. Now bobbin is

ready to be used for weaving (Figure 4.6).

Related Topics