Chapter: Environmental Engineering : Collection and conveyence System of water

Water Network Maintenance

WATER

NETWORK MAINTENANCE

Water supply networks usually represent the majority

of assets of a water utility. Systematic documentation of maintenance works

using a Computerized Maintenance Management System is a key to a successful

operation of a water utility.

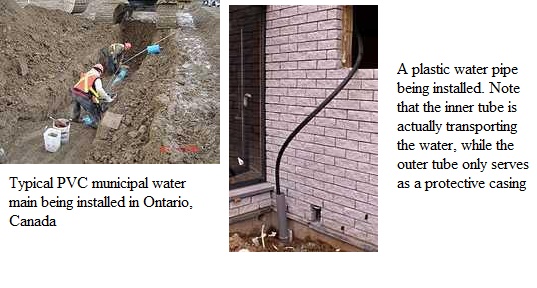

Water

pipe

Water pipes are

pipes or tubes, frequently made of polyvinyl chloride (PVC/uPVC), ductile iron,

steel, cast iron, polypropylene, polyethylene, or copper, that carry

pressurized and treated fresh water to buildings (as part of a municipal water

system), as well as inside the building.

Pipe

vs. tube

The difference between pipe and tube is simply in

the way it is sized. PVC pipe for plumbing applications and galvanized steel

pipe for instance, are measured in IPS (iron pipe size). Copper tube, CPVC, PeX

and other tubing is measured nominally, which is basically an average diameter.

These sizing schemes allow for universal adaptation of transitional fittings.

For instance, 1/2" PeX tubing is the same size as 1/2" copper tubing.

1/2" PVC on the other hand is not the same size as 1/2" tubing, and

therefore requires either a threaded male or female adapter to connect them.

When used in agricultural irrigation, the singular form "pipe" is

often used as a plural.

Piping is available in rigid "joints",

which come in various lengths depending on the material. Tubing, in particular

copper, comes in rigid hard tempered "joints" or soft tempered

(annealed) rolls. PeX and CPVC tubing also comes in rigid "joints" or

flexible rolls. The temper of the copper, that is whether it is a rigid

"joint" or flexible roll, does not affect the sizing.

The thicknesses of the water pipe and tube walls can

vary. Pipe wall thickness is denoted by various schedules. Pipe wall thickness

increases with schedule, and is available in schedules 20, 40, 80, and higher

in special cases. The schedule is largely determined by the operating pressure

of the system, with higher pressures commanding greater thickness. Copper

tubing is available in four wall thicknesses: type DWV (thinnest wall; only

allowed as drain pipe per UPC), type 'M' (thin; typically only allowed as drain

pipe by IPC code), type 'L' (thicker, standard duty for water lines and water

service), and type 'K' (thickest, typically used underground between the main

and the meter). Because piping and tubing are commodities, having a greater

wall thickness implies higher initial cost. Thicker walled pipe generally

implies greater durability and higher pressure tolerances.

Wall thickness does not affect pipe or tubing size.

1/2" L copper has the same outer diameter as 1/2" K or M copper. The

same applies to pipe schedules. As a result, a slight increase in pressure

losses is realized due to a decrease in flowpath as

wall thickness is increased. In other words, 1 foot of 1/2" L copper has

slightly less volume than 1 foot of 1/2 M copper.[citation needed]

Demand for copper

products have fallen due to the dramatic increase in the price of copper,

resulting in increased demand for alternative products including PEX and

stainless steel.

Related Topics