Chapter: Mechanical : Manufacturing Technology : Abrasive Process and Broaching

Surface broaches and Continuous Chain Broaching

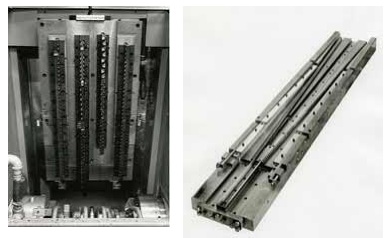

Surface broaches

The broaches used to remove material from an

external surface are commonly known as surface broaches. Such broaches are

passed over the workpiece surface to be cut, or the workpiece passes over the

tool on horizontal, vertical or chain machines to produce flat or contoured

surfaces.

While some surface broaches are of solid

construction, most are of built-up design, with sections, inserts or indexable

tool bits that are assembled end-to-end in a broach holder or sub holder. The

holder fits on the machine slide and provides rigid alignment and support.

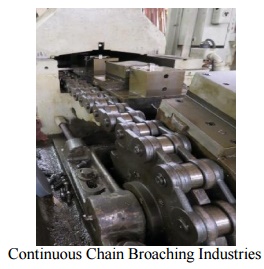

Continuous Chain Broaching

Continuous chain, or simply chain

broaching refers to the type of machine that is used to broach a piece part.

Chain

broaching is oriented towards high volume production, and is an extremely fast

and efficient operation. However, because the fixtures used to hold the piece

parts are mounted on chains that are driven by sprockets, it is difficult to

hold extremely close tolerances. This process is suitable for high-volume,

external cutting.

Continuous

Chain Broaching Industries

·

Biomedical

·

Electronics

·

Defense

A chain broaching machine resembles a very long tunnel, through which passes a series of holding fixtures, or cars. Piece parts are loaded, usually automatically, into the cars, which themselves are mounted on, and carried through the tunnel by a very large continuous chain. The broach tooling is mounted on the inside walls of the tunnel, and this tooling cuts the piece part as it passes through the tunnel. Contact us today to learn more.

Related Topics