Chapter: Mechanical : Manufacturing Technology : Abrasive Process and Broaching

Centerless grinding and Internal Grinding

Centerless

grinding

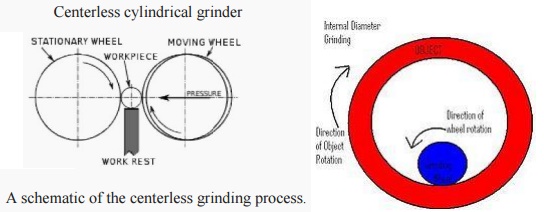

Centerless cylindrical grinder

A schematic of the centerless grinding process.

Centerless

grinding is a form of grinding where there is no

collet or pair of centers holding the object

in place. Instead, th ere is a regulating wheel positioned on the o pposite

side of the object to the grinding wheel. A work rest keeps the object at the

appropriate height but has no bearing on its rotary speed. The workblade is

angled slightly towa rds the regulating wheel, with the workpiece c enterline

above the centerlines of the regul ating and grinding wheel; this means that

high spots do not tend to generate corresponding o pposite low spots, and hence

the roundness of parts can be improved. Centerless grinding is much easier to

combine with automatic load ing procedures than centered grinding; thr oughfeed

grinding, where the regulating wheel is held at a slight angle to the part so

that ther e is a force feeding the part through the grinder, i s particularly

efficient.

Internal

Grinding

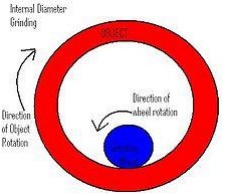

A basic overview of Internal Diameter Cylindrical Grinding. The Curve d Arrows refer to direction of rotation.

ID grinding is

grinding occurring on the inside of an object. The grinding wheel is always

smaller than the width of the object. The object is held in place by a collet, which also rotates the object in place. Just as with OD

grinding, the grinding wheel and the object rotated in opposite directions

giving reversed direction contact of the two surfaces where the grinding

occurs.

Related Topics