Chapter: Civil : Construction Materials: Timber And Other Materials

Steel

Steel

Steel is the most suitable

building material among metallic materials. This is due to a wide range and

combination of physical and mechanical properties that steels can have. By

suitably controlling the carbon content, alloying elements and heat treatment,

a desired combination of hardness, ductility, and strength can be obtained in

steel. On the basis of carbon content steel may be classified as under:

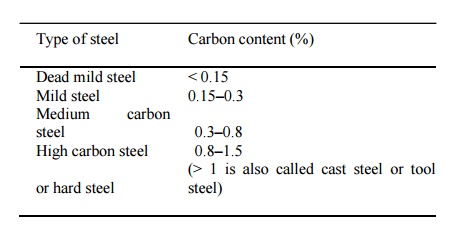

Type of steel Carbon content (%)

Dead

mild steel < 0.15

Mild

steel 0.15-0.3

Medium carbon steel 0.3-0.8

High

carbon steel or hard steel 0.8-1.5

(> 1 is also called cast steel or tool steel)

1 Manufacturing Methods

The

prominent steel-making processes are:

1. Bessemer process

2. Cementation process

3. Crucible process

4. Open Hearth process

5. Electric Smelting process

6. Duplex process

7. Lintz and Donawitz (L.D.) process

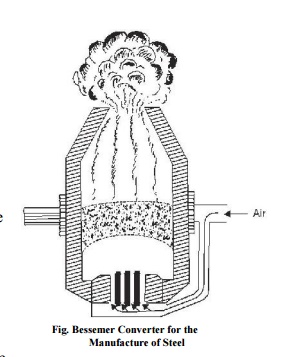

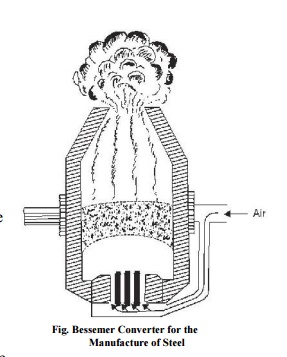

The most prominent

present-day steel-making process is the Bessemer process was introduced in

1856. The pig iron is first melted in Cupola furnace and sent to Bessemer

converter (Fig. ) Blast of hot air is given to oxidize the carbon. Depending

upon the requirement, some carbon and manganese is added to the converter and

hot air is blasted once again. Then the molten material is poured into moulds

to form ingots. L.D. process is modification of the Bessemer process in which

there in no control over temperature. By this method steel can be made in

hardly 25 minutes. In Open-hearth process also known as Siemen's-Martin

process, the steel produced is more homogeneous than by Bessemer's. The

electric process is costly but no ash or smoke is produced. The

Crucible process involves melting of blister steel or bars of wrought iron in

fire clay crucibles. Cast steel so obtained is very hard and is used for making

surgical equipments. The Duplex process is a combination of Acid Bessemer

process and Basic Open Hearth process

2 Properties and Uses

Mild Steel Also

known as low carbon or soft steel. It is ductile, malleable; tougher and more

elastic than wrought iron. Mild steel can be forged and welded, difficult to

temper and harden. It rusts quickly and can be permanently magnetized. The

properties are: Sp. gr. = 7.30, ultimate compressive and tensile strengths 800-1200N/mm2

and 600- 800N/mm2.

Mild steel is used in the form of

rolled sections, reinforcing bars, roof coverings and sheet piles and in

railway tracks.

High Carbon Steel: The

carbon content in high carbon steel varies from 0.55 to 1.50%. It is

also known as hard steel. It is tougher and more elastic than mild steel. It

can be forged and welded with difficulty. Its ultimate compressive and tensile

strengths are 1350 N/mm2 and 1400-2000 N/mm2,

respectively. Its Sp. gr. is 7.90.

High carbon steel is used for

reinforcing cement concrete and prestressed concrete members. It can take

shocks and vibrations and is used for making tools and machine parts.

High Tensile steel: The

carbon content in high tensile steel is 0.6-0.8%,

manganese 0.6%, silicon 0.2%, sulphur 0.05% and phosphorus 0.05%. It is

also known as high strength steel and is essentially a medium carbon steel. The

ultimate tensile strength is of the order of 2000 N/mm2 and a

minimum elongation of 10 per cent.High Tensile steel is used in prestressed

concrete construction.

3 Properties of Steel

The factors influencing the

properties of steel are chemical composition, heat treatment, and mechanical

work.

Chemical Composition

The presence of carbon in steel

gives high degree of hardness and strength. The addition of carbon to iron

decreases the malleability and ductility of the metal, and reduces its

permeability to magnetic forces.

The

tensile strength of hot rolled steel bars is maximum between 1.0 and 1.2 per

cent carbon. The elastic limit and the ultimate strength of steel increase with

carbon content but at a lower rate. The compressive strength of steel increases

directly with carbon content up to 1.0 per cent. The shear strength of steel

also increases with the carbon content. The ratio of shear strength to the

tensile strength is 0.80 for medium and low carbon steels and 0.60 for high

carbon steels. The modulus of elasticity is nearly same for tension and

compression and is practically independent of the carbon content.

The ductility of steel decreases

markedly as the carbon content increases. The resistance of steel to heavy

shocks or blows decreases with increase of carbon content.

Effects of Principal Impurities

on Steel: It is not feasible to entirely remove impurities in

making either iron or steel. The final product always contains small

percentages of the metallic impurities like silicon, manganese, sulphur, and

phosphorus besides iron and carbon. Occasionally small percentages of copper

and arsenic are also present. In well made steel these impurities generally

range between 0.2 and 1.0 per cent and their resultant effect on the

constitution of steel is often small. Of the common impurities, Phosphorus

cannot be eliminated in the process of manufacture, whereas most of the silicon

and manganese are introduced to improve the metal.

Silicon is often added to molten

metal to remove oxygen and diminish blow holes. In structural steel it rarely

exceeds 0.25 per cent. Silicon up to 1.75 per cent appears to increase both

ultimate strength and elastic limit without decreasing ductility.

Phosphorus is considered to

promote enlargement of the grains and thus produce brittleness. The ductility

of low-carbon steel decreases slightly by the presence of 0.3-0.5 per

cent phosphorus. However, yield point, ultimate strength and hardness of steel

are increased. Resistance to shock is also reduced by 0.1 per cent phosphorus

and the metal is rendered cold short (i.e., brittle when cold). A decrease in

toughness appears to be more pronounced in high-carbon than in low-carbon

steels. The maximum limits for phosphorus are: for inferior grades of

structural steel 0. 1, for best grades of structural steel 0.055, and 0.02 per

cent for tool steels.

Sulphur readily combines with

iron to form iron sulphide (FeS) which, when present in iron or steel, has a

tendency to segregate and form brittle networks at the grain boundaries. On

account of its low melting point, iron sulphide causes lack of cohesion between

adjacent grains when heated above a red heat. Such brittleness at high

temperature is termed as red shortness which makes steel or iron hard to roll

or forge. Manganese sulphide has a much higher melting point than iron

sulphidle and does not render ferrous metals red short. Therefore, inasmuch as

manganese has a very powerful affinity for sulphur, it is possible to relieve

red shortness by adding sufficient quantity of manganese to the molten metal to

combine with sulphur. Theoretically the ratio of manganese to sulphur should be

1.70 to 1.0 in order to form manganese sulphide and completely satisfy sulphur.

Less than 0.15 per cent sulphur content hardly exercises any appreciable effect

on the mechanical properties of steel. When sulphur is present along with

manganese it improves the machineability of steel.

Manganese has strong affinity for

oxygen and sulphur and acts as a cleanser of the molten metal by withdrawing

much of the undesirable impurities into the slag. Manganese increases the

tensile strength, hardenability and dilutes the effect of sulphur. When more

manganese is present than required for sulphur and oxygen the excess manganese

forms carbide and acts as hardener. Copper increases resistance to corrosion

when present in small percentage. Arsenic has a tendency to raise the strength

and brittleness. Non-metallic Impurities are mechanically suspended in the

metal and are often called slag inclusions causing brittleness.

Heat Treatment

The object of heat treatment is

to develop desired properties in steel. The properties of steel can be

controlled and changed as well by various heat treatments. A steel of given

composition may be made soft, ductile and tough by one heat treatment, and the

same steel may be made relatively hard and strong by another. Heat treatment

affects the nature, amount, and character of the metallographic properties.

Heat treatment influences the

solubility relations of the constituents, changes the crystallization either

with respect to form or degree of aggregation and introduces or relieves

internal stresses in the metal. The heat treatment process consists in

subjecting, a metal to definite temperature-time

course.

Some of

the principle purposes of heat treatment are as follows.

1. To

enhance properties such as strength, ductility, hardness and toughness.

2. To

relieve internal stresses and strains.

3. To refine

the grain.

4. To remove

gases.

5. To

normalize steel after heat treatment.

Hardening

This heat treatment consists of

heating the steel above the upper critical temperature holding at that

temperature until phase equilibrium has been established, and then quenching

rapidly to produce a martensite structure. Martensite is the chief constituent

of hardened steel and is fibrous or needle like structure. Hardened steel is

very brittle and cannot be used for practical purposes. The quenching medium is

usually brine, water or oil, depending on the desired cooling rate.

The objective of this treatment

may be to secure a given hardness to a desired depth in steel. But in most

instances the hardening treatment may simply be considered as starting point

from which better combinations of desired properties may be secured by

subsequent heat treatment. Fully hardened steel are not suitable for most

commercial uses because they are hard and brittle and have poor toughness.

Tempering

A plain

carbon steel that has been hardened is in metastable condition or equilibrium.

If this hardened steel is reheated to some temperature below the critical

range, a more stable condition will be obtained. Since hardened steels do not

usually have the combination of properties desired for specific uses,

modification is affected by tempering.

When a thick piece of steel is

cooled rapidly it develops additional strains as the surface cools quicker than

the interior. To relieve this strain, steel is subjected to the process

tempering which consists in slowly heating the steel to a predetermined

subcritical temperature and then cooling it slowly. This temperature varies

from 100 o C to 700 o C. The higher the temperature of tempering the softer is the

product. The properties like toughness and ductility are automatically

introduced with release of strain.

Annealing

It is a general term used for

heating and slow cooling of metal, glass or any other material, which has

developed strain due to rapid cooling.

The process consists of heating

the steel to a temperature below the critical range, but high enough to obtain

strain re-crystallization and then cooled in any manner. The exact heating

temperature depends on the composition of steel and the amount of work that it

has received, but is frequently between 500 o C to 600 o C. Annealing of steel in

addition to removing strain introduces one or more of the following properties.

1. Introduces

softness, ductility, and malleability.

2. Alters

electrical, magnetic, and other physical properties.

3. Produces

a definite microstructure and grain refinement.

4. Removes

gases.

Full annealing consists of

heating iron alloy 20 o C to 50 o C above critical temperature range, holding at

that temperature for the required period of time to convert it to austenite

followed by slow cooling. Full annealing usually decreases hardness, strength,

and resistance to abrasion, and increases ductility and merchantability.

Normalizing

It consists in heating steel

above critical range and cooling rapidly in air, but at rate slower than the

critical cooling rate. The purpose of this heat treatment is to refine the

grain structure resulting from rolling, forging or other manufacturing

processes.

Mechanical Works

Steel products are made by

casting molten refined steel of suitable composition into the desired form or

by mechanically working steel form the ignot through many intermediate forms to

the desired product. Mechanical work may be hot or cold. Mechanical working

involves many stages of hot working and may or may not include eventual cold

working.

The most important methods of hot

working steel are hot rolling, hammer forging, hydraulic and mechanical press

forging, and hot extrusion. Miscellaneous hot working methods include hot

spinning, hot deep drawing, hot flanging and hot bending, Heat treatment after

hot working is seldom used with low-carbon steels, whereas high-carbon steels

are always hardened and tempered.

The

principle methods of cold working steel are cold rolling, cold drawing and cold

extrusion. The cold working methods are used to provide increased strength,

accurate dimensions, and bright and scale free surfaces. Thin sheets and small

diameter wires are produced by cold-working methods. Cold working results in

increased density, hardness, and brittleness, and produces an internally

strained condition in the steel.

Mechanical work alters the form of the crystalline

aggregate and introduces internal stresses. Cold rolling increases the tensile

elastic limit from 15 to 97 per cent and tensile strength from 20 to 45 per

cent. In elastic resilience the cold-rolled metal is superior to the

hot-rolled, whereas in energy of rupture it is inferior to the hot-rolled

metal. The modulus of elasticity is slightly increased by cold rolling.

Practically, metals are rolled, forged, drawn, stamped and pressed.

Most of

steel building components-beams, rails, steels, bars,

reinforcement, pipes- are manufactured by rolling.

Rivets and bolts are made by forging operations. Thin-walled items (tubes) and

round, square, hexagonal rods of small cross-sectional areas (up to 10 mm2)

are manufactured by drawing. Stamping and pressing increases the buckling

strength of plates to be used for making them suitable for steel tanks and

containers. Steel trusses, towers, tanks, bridges and frames of multistorey

buildings are some of the examples of structures made of steel. The most common

and important application of steel in buildings is the rolled steel sections

and reinforcing bars and are described in the following sections.

Related Topics