Chapter: Civil : Construction Materials: Timber And Other Materials

Aluminum

Aluminum

The principal constituents of

bauxite (Al2O32H2O) which yield aluminum on a

commercial scale are hydrated oxides of aluminum and iron with some silica.

Some of the other aluminum ores are

corundum, kaolin or china clay, and kryolite. The ore is purified by

Bayer's process and is reduced to aluminum by

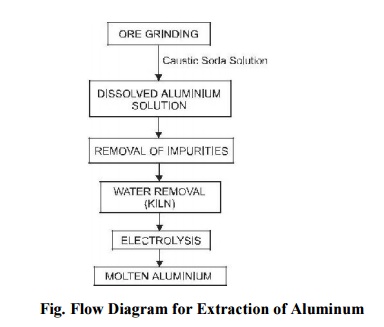

Hall Hiroult's process in two stages. In the first stage bauxite is

converted into alumina by roasting, grinding, heating (with sodium hydrate) and

filtering. Then it is agitated for several hours to precipitate the hydrate,

which is separated, washed, and calcined at 1000 o C. In the next stage aluminum

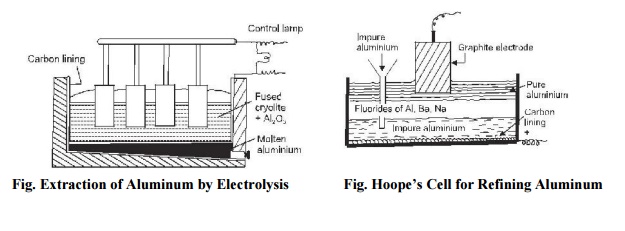

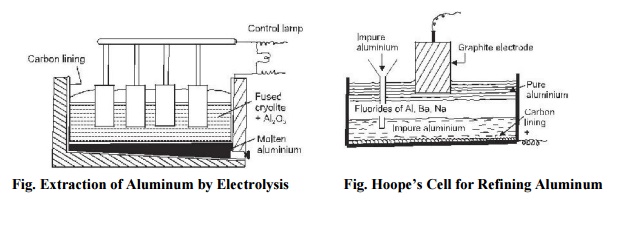

is extracted by electrolysis of alumina in a molten bath (Fig. 14.1) of

crystolite (a fluoride of alumina and sodium). A flow diagram for extraction of

aluminium is shown in Fig.

Aluminum is silver white in

colour with a brittle metallic lustre on freshly broken surface. It is

malleable, less ductile than copper but excels zinc, tin, and lead. Aluminium

is harder than tin. Aluminium is very light, soft, strong and durable, has low

thermal conductivity but is a good conductor of electricity. Aluminium can be

riveted and welded, but cannot be soldered. It can be tempered at 350 o C. The

melting point is 657 o C, tensile strength is 117.2 N/mm2 in the cast

form and 241.3 N/mm2 when drawn into wires. Aluminium is found to be

resistant to the attack of nitric acid, dissolves slowly in concentrated

sulphuic acid and is soluble in hydrochloric acid. At normal temperature it is

not affected by sulphur, carbonic acid, carbonic oxide, vinegar, sea water,

etc., but is rapidly corroded by caustic alkalis.

Uses Pure

aluminum is very soft and is unsuitable for structural purposes. Satisfactory

properties are derived by alloying copper, manganese, zinc, silicon, nickel

with aluminum. It is most suitable for making door and window frames, railings

of shops and corrugated sheets for roofing system. Aluminum sheets are used

over doors in bathrooms to protect them from getting rot and for stamping into

a variety of shapes. Aluminum powder is used for making paint. Aluminum is

extensively used in making parts of internal combustion engine, airplanes,

utensils and packing for medicines, chocolates, etc. Aluminum alloys are widely

used for the manufacture of rolled sections, such as angles, channels,

I-sections, round and rectangular pipes, rivets, and bolts

Alloys

Aluminum

is commonly alloyed with copper silicon, magnesium, or zinc to improve its

mechanical properties. Some aluminum alloys also contain one or more of the

metals manganese, lead, nickel, chromium, titanium, and beryllium. A large part

of the aluminum production is utilized in making light, stiff,

corrosion-resistant alloys with these metals. Aluminum alloys may be classed as

the cast alloys, which are shaped by casting and wrought alloys, which are

worked into different shapes by mechanical operations. Cast alloys are generally

binary alloys containing copper or silicon, and sometimes magnesium. Wrought

alloys contain copper, magnesium, silicon, and manganese that form

precipitation hardening alloys with aluminum. Following are some of the

aluminum alloys.

Duralumin contains

3-5%

copper, 0.51-1% magnesium and 0-0.07%

manganese. 0.3-0.6% iron and 0.3%-0.6%

silica are present as impurities. The relative density is 2.80, which is quite

low as compared to that of mild steel. However, when rolled and heat treated

tensile strength equals that of mild steel. Its yield point is 206.85 N/mm2.

It is highly resistant to corrosion. Wire and sheets are drawn from duralumin.

Duralumin may be fabricated into different structural shapes to be used for

construction.

Magnesium is an

alloy of aluminum and magnesium (6 per cent). It has got very good mechanical

properties and is a little lighter than pure aluminum. It is easy to work,

exceptionally strong, and ductile and is widely used as deoxidizers in copper

smelting operations.

Aldural When a

coating of aluminum is given to duralumin it is known as aldural and has

better corrosion resisting properties.

Y-alloy invented

during World War II contains 4 per cent copper, 20 per cent nickel and

1.5 per cent magnesium. Toughness and hardness are achieved by heating it to

500 o C for six hours and then cooling it down in boiled water. Its relative

density is 2.80 and resists corrosion better than duralumin. Y-alloy has good

thermal conductivity and can sustain high temperature. It is used for making

pistons of I.C. engines, cylinder head, connecting rod and propeller blades.

Aluminium Bronze contains

less than 11 per cent of aluminium and is rather inappropriately named.

It is highly ductile when aluminium is less than 7.3 per cent. As the aluminium

increases, ductility decreases and at 12 per cent the alloy is very brittle.

Bronzes containing less than 7.3 per cent aluminium are highly resistant to

torsional stress, readily rolled, forged, cold drawn, exhibit toughness under

impact and resistance to alternate bending stress.

An input of 1 per cent of

maganese into 10 per cent aluminum bronze increases the yield point and

ductility without change in strength or endurance under reversal of stress. The

modulus of elasticity of aluminium bronze is about 1.03425 × 10 5

N/mm2. These are almost incorrodible in sea water and in this

respect are superior to Muntz metal or naval brass.

Aluminium bronze is used for pump

lines, tubes, springs, screws, rivets, ornamental works, marine engineering

castings, motor boat shafting, musical instruments, and as a substitute of mild

steel to resist corrosion, grill works, etc.

Light

Alloy contains 3 per cent copper and 12 per cent zinc. It is used

for castings such as crank and gear housings. Aluminium-Copper Alloy

contains copper up to 4 per cent. Less liable to burning the alloy produces

light castings that are stronger and tougher than that made from aluminium. It

is mainly used in automobile industry for casting.

Aluminium-Zince Alloy contains

zince up to 15 per cent and is used for light casting which can be

easily machined or forged into desired form. These are very sensitive to high

temperatures in melting and in solid form exhibit low strength and brittleness

when heated above 50 o C. Alloys containing 15 to 25 per cent zinc are harder,

stronger, but less ductile and more difficult to roll or draw. If percentage of

zinc is increased above 25 the alloy suffers decrease in strength when

excessively worked, either hot or cold. Aluminium zinc alloys have well defined

yield points. Aluminium-Silicon Alloy Aluminium alloys containing

5 to 15 per cent silicon are important because their excellent casting

qualities, including excellent fluidity and freedom from hot-shortness, permit

the pouring of thin intricate sections. They also have high resistance to

corrosion, are good conductors of heat, and have low thermal expansion

Aluminium composite panel (ACP)

also aluminium composite material, (ACM) is a type of flat

panel that consists of two thin aluminium sheets bonded to a non-aluminium

core. ACPs are frequently used for external cladding or facades of buildings,

insulation, and signage.[3]

Aluminium sheets can be coated

with polyvinylidene fluoride (PVDF), fluoropolymer resins (FEVE), or polyester

paint. Aluminium can be painted in any kind of colour, and ACPs are produced in

a wide range of metallic and non-metallic colours as well as patterns that imitate

other materials, such as wood or marble. The core is commonly low density

polyethylene, or a mix of low density polyethylene and mineral material to

exhibit fire retardant properties.

3A Composites (formerly Alcan

Composites & Alusuisse) invented aluminium composites in 1964 and

commercial production of Alucobond commenced in 1969, followed by Dibond 20

years later.

1 Applications

Sandwich panels are used in those

applications where high structural rigidity and low weight is required. An

evident example of use of sandwich panels is aircraft where mechanical

performance and weight saving is essential. Other applications include

packaging (e.g. fluted polypropylene boards of polypropylene honeycomb boards),

transportation and automotive as well as building & construction.

ACP is mainly used for external

and internal architectural cladding or partitions, false ceilings, signage,

machine coverings, container construction etc. Applications of ACP are not

limited to external building cladding, but can also be used in any form of

cladding such as partitions, false ceilings etc. ACP is also widely used within

the signage industry as an alternative to heavier, more expensive substrates.

Epcot's

Spaceship Earth is an example of the use of ACP in architecture. It is a

geodesic sphere composed of 11,324 ACP tiles.

ACP has been used as a

light-weight but very sturdy material in construction, particularly for

transient structures like trade show booths and similar temporary elements. It

has recently also been adopted as a backing material for mounting fine art

photography, often with an acrylic finish using processes like Diasec or other

face-mounting techniques. ACP material has been used in famous structures as

Spaceship Earth, VanDusen Botanical Garden, the Leipzig branch of the German

National Library.

These structures made optimal use

of ACP through its cost, durability and efficiency. Its flexibility, low weight

and easy forming and processing allow for innovative design with increased

rigidity and durability.

2 Other names

Many people use Alucobond

or sandwich panel as a generic name (genericized trademark) for aluminum

composite panels that are typically 0.3 to 0.5 mm thick aluminum sheets

covering a solid polyethylene core with a total thickness of 3 mm or more, or

similar panels from any manufacturer.[9]

A variety of manufacturers sell

aluminium composite panels under a wide variety of brand names, including: (in

no particular order)

Alucobond from 3A Composites,

ALPOLIC from Mitsubishi Plastics, Aluminum wall claddings from Guangzhou Xinghe

Aluminum Co, Ltd Reynobond from Alcoa, Envelope 2000 from CitadelAP, Aludecor

from HMB Group, Larson from Alucoil, Hylite from 3A Composites, VillaBOND from

Villa Bond, Dibond from 3A Composites and Alcan, WILLSTRONG from WILLSTRONG CO.

Max-Metal from Grimco, RedBond from aRedBond Composites, Vitrabond from

Fairview Architectural, Plascore Board from Plascore, Alupanel and Alupanel XT

are manufactured by Multipanel UK in their own UK factory, Etalbond from Elval

Colour, AlubondAfrica, Pink Rhino from Pettongtana etc.

Some people

use sandwich panel

for any structural

sandwich (sandwich-

structured composite) of a core

bonded between two cover sheets, no matter what material(s) it is made of, and

no matter if the core is solid, foam, flutes, or honeycomb.[10]

3 The selective use of ACP

An important aspect to discuss

here is the haphazard use of ACP, a trend for which the user is responsible and

not the material. One can witness the use of ACP in newly constructed buildings

in areas of historic importance without any regard to the built environment of

the place thus ruining the architectural, historic and cultural fabric of the

place.

It can be argued that ACP is a

stylish and sensible innovation, which can prove to be a blessing for

commercial as well as decorative purposes. Yet one should be aware of its

benefits as well as demerits, and also realize its installation process and

features. This would result in the proper use of the material instead of the

haphazard nature of its current introduction into the buildings in the city.

Paint is a liquid surface

coating. On drying it forms a thin film (60-150 m) on

the painted surface. Paints are classified as oil paints, water paints, cement

paints, bituminous paints and special paints such as fire proof paints,

luminous paints, chlorinated rubber paints (for protecting objects against acid

fumes), etc.

The functions of the paints are:

to protect the coated surface against possible stresses-

mechanical or chemical; deterioration-physical

or environmental; decorate the structure by giving smooth and colourful finish;

check penetration of water through R.C.C; check the formation of bacteria and

fungus, which are unhygienic and give ugly look to the walls; check the

corrosion of the metal structures; check the decay of wood work and to varnish

the surface to display it to better advantage.

Related Topics