Chapter: Mechanical and Electrical : Thermal Engineering : Steam Nozzles and Turbines

Steam Nozzles and Turbines

STEAM NOZZLES AND TURBINES

PREREQUISITE DISCUSSIONS

A steam

turbine is basically an assembly of nozzles fixed to a stationary casing and

rotating blades mounted on the wheels attached on a shaft in a row-wise manner.

In 1878, a Swedish engineer, Carl G. P. de Laval developed a simple impulse

turbine, using a convergent-divergent (supersonic) nozzle which ran the turbine

to a maximum speed of 100,000 rpm. In 1897 he constructed a velocity-compounded

impulse turbine (a two-row axial turbine with a row of guide vane stators

between them.

Auguste

Rateau in France started experiments with a de Laval turbine in 1894, and

developed the pressure compounded impulse turbine in the year 1900.

In the

USA , Charles G. Curtis patented the velocity compounded de Lavel turbine in

1896 and transferred his rights to General Electric in 1901.

In

England , Charles A. Parsons developed a multi-stage axial flow reaction

turbine in

1884.

Steam

turbines are employed as the prime movers together with the electric generators

in thermal and nuclear power plants to produce electricity. They are also used

to propel large ships, ocean liners, submarines and to drive power absorbing

machines like large compressors, blowers, fans and pumps.

Turbines

can be condensing or non-condensing types depending on whether the back

pressure is below or equal to the atmosphere pressure.

STEAM NOZZLE

Introduction

A steam

turbine converts the energy of high-pressure, high temperature steam produced

by a steam generator into shaft work. The energy conversion is brought about in

the following ways:

1. The

high-pressure, high-temperature steam first expands in the nozzles emanates as

a high velocity fluid stream.

2. The high

velocity steam coming out of the nozzles impinges on the blades mounted on a

wheel. The fluid stream suffers a loss of momentum while flowing past the

blades that is absorbed by the rotating wheel entailing production of torque.

3. The

moving blades move as a result of the impulse of steam (caused by the change of

momentum) and also as a result of expansion and acceleration of the steam

relative to them. In other words they also act as the nozzles.

Flow Through Nozzles

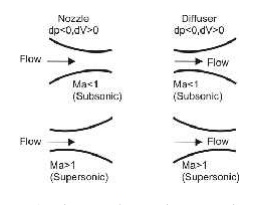

Ø A nozzle

is a duct that increases the velocity of the flowing fluid at the expense of

pressure drop.

Ø A duct

which decreases the velocity of a fluid and causes a corresponding increase in

pressure is a diffuser .

Ø The same

duct may be either a nozzle or a diffuser depending upon the end conditions

across it. If the cross-section of a duct decreases gradually from inlet to

exit, the duct is said to be convergent.

Ø Conversely

if the cross section increases gradually from the inlet to exit, the duct is

said to be divergent.

Ø If the

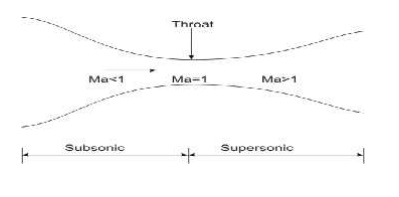

cross-section initially decreases and then increases, the duct is called a

convergent-divergent nozzle.

Ø The

minimum cross-section of such ducts is known as throat.

Ø A fluid

is said to be compressible if its density changes with the change in

pressure brought about by the flow.

Ø If the

density does not changes or changes very little, the fluid is said to be

incompressible. Usually the gases and vapors are compressible, whereas liquids

are incompressible .

Shapes of nozzles

1. At

subsonic speeds (Ma<1) a decrease in area increases the speed of flow.

2. In

supersonic flows (Ma>1), the effect of area changes are different.

Convergent divergent nozzles

SIGNIFICANCE OF STEAM

TURBINES

Ø Large

scale electrical energy production largely depends on the use of turbines.

Nearly all of the world's power that is supplied to a major grid is produced by

turbines.

Ø From

steam turbines used at coal-burning electricity plants to liquid water turbines

used at hydro-electric plants, turbines are versatile and can be used in a

number of applications.

Ø There are

also gas turbines that combust natural gas or diesel fuel for use in remote

locations or where a large backup power supply is required. Most power plants

use turbines to produce energy by burning coal or natural gas.

Ø The heat

produced from combustion is used to heat water in boiler. The liquid water is

converted to steam upon heating and is exhausted through a pipe which feeds the

steam to the turbine.

Ø The

pressurized steam flow imparts energy on the blades and shaft of the turbine

causing it to rotate.

Ø The

rotational mechanical energy is then converted to electrical energy using a

generator.

STEAM TURBINES

Turbines

Ø We shall

consider steam as the working fluid

Ø Single

stage or Multistage

Ø Axial or

Radial turbines

Ø Atmospheric

discharge or discharge below atmosphere in condenser

Ø Impulse/and

Reaction turbine

Impulse Turbines

Ø Impulse

turbines (single-rotor or multirotor) are simple stages of the turbines.

Ø Here the

impulse blades are attached to the shaft.

Ø Impulse

blades can be recognized by their shape.

Ø The

impulse blades are short and have constant cross sections.

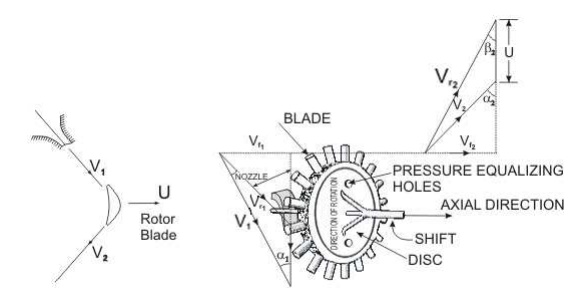

Schematic diagram of an

Impulse Trubine

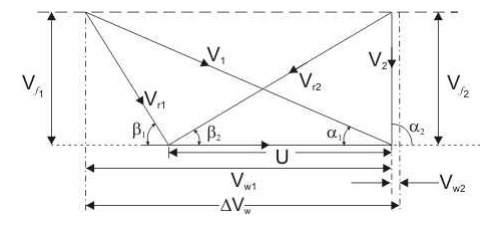

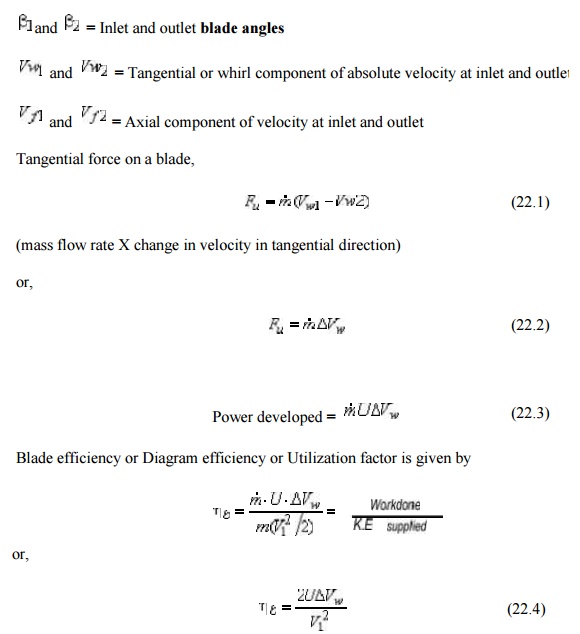

V1 and V2 = Inlet

and outlet absolute velocity

Vr1 and V r2 = Inlet and

outlet relative velocity (Velocity relative to the rotor blades.)

U = mean blade speed

= nozzle angle,

=

absolute

fluid angle at outlet

It is to be mentioned that all

angles are with respect to the tangential velocity ( in the direction of U )

Velocity diagram of an

Impulse Turbine

The Single-Stage Impulse

Turbine

Ø The single-stage

impulse turbine is also called the de Laval turbine after its

inventor.

Ø The

turbine consists of a single rotor to which impulse blades are attached.

Ø The steam

is fed through one or several convergent-divergent nozzles which do not extend

completely around the circumference of the rotor, so that only part of the

blades is impinged upon by the steam at any one time.

Ø The

nozzles also allow governing of the turbine by shutting off one or more them.

Compounding in Impulse

Turbine

Ø If high

velocity of steam is allowed to flow through one row of moving blades, it

produces a rotor speed of about 30000 rpm which is too high for practical use.

Ø It is

essential to incorporate some improvements for practical use and also to

achieve high performance.

Ø This is

called compounding.

Ø Two types

of compounding can be accomplished: (a) velocity compounding and (b) pressure

compounding

The Velocity - Compounding

of the Impulse Turbine

Ø The

velocity-compounded impulse turbine was first proposed to solve the problems of

a single-stage impulse turbine for use with high pressure and temperature

steam.

Ø It is

composed of one stage of nozzles as the single-stage turbine, followed by two

rows of moving blades instead of one.

Ø These two

rows are separated by one row of fixed blades attached to the turbine stator,

which has the function of redirecting the steam leaving the first row of moving

blades to the second row of moving blades.

Pressure Compounding or

Rateau Staging

Ø To

alleviate the problem of high blade velocity in the single-stage impulse

turbine, the total enthalpy drop through the nozzles of that turbine are simply

divided up, essentially in an equal manner, among many single-stage impulse

turbines in series,Such a turbine is called a Rateau turbine.

Ø The

inlet steam velocities to each stage are essentially equal and due to a reduced

Δh.

Reaction Turbine

Ø A reaction

turbine, therefore, is one that is constructed of rows of

fixed and rows of moving blades.

Ø The fixed

blades act as nozzles.

Ø The

moving blades move as a result of the impulse of steam received (caused by

change in momentum) and also as a result of expansion and acceleration of the

steam relative to them.

Ø The

pressure drops will not be equal.

Ø They are

greater for the fixed blades and greater for the high-pressure than the

low-pressure stages.

Ø The

absolute steam velocity changes within each stage as shown and repeats from

stage to stage.

APPLICATIONS

Ø Locomotives

Ø Power

generations

Ø Industrial

application for producing steam

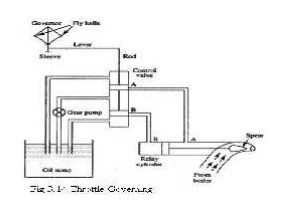

Governing of Steam Turbine: The

method of maintaining the turbine speed constant irrespective of the

load is known as governing of turbines. The device used for governing of

turbines is called Governor. There are 3 types of governors in steam turbine,

1. Throttle

governing

2. Nozzle

governing

3. By-pass

governing

i.Throttle Governing:

Let us consider an instant when the load on the

turbine increases, as a result the speed of the turbine decreases. The fly

balls of the governor will come down. The fly balls bring down the sleeve. The

downward movement of the sleeve will raise the control valve rod. The mouth of

the pipe AA will open. Now the oil under pressure will rush from the control

valve to right side of piston in the rely cylinder through the pipe AA. This

will move the piston and spear towards the left which will open more area of

nozzle. As a result steam flow rate into the turbine increases, which in turn

brings the speed of the turbine to the normal range.

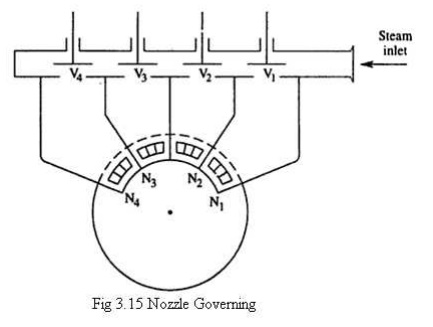

ii)Nozzle Governing:

A dynamic arrangement of nozzle control governing

is shown in fig.

In this nozzles are grouped in 3

to 5 or more groups and each group of nozzle is supplied steam controlled by

valves. The arc of admission is limited to 180º or less. The nozzle controlled

governing is restricted to the first stage of the turbine, the nozzle area in

other stages remaining constant. It is suitable for the simple turbine and for

larger units which have an impulse stage followed by an impulse reaction

turbine.

Solved

Problems:

1. A convergent divergent

adiabatic steam nozzle is supplied with steam at 10 bar and 250°c.the discharge

pressure is 1.2 bar.assuming that the nozzle efficiency is 100% and initial

velocity of steam is 50 m/s. find the discharge velocity.

Given Data:-

Initial

pressure(p1)=10bar Initial

Temperature(T1)=250°c

Exit

pressure(p2)=1.2 bar

Nozzle

efficiency(ηnozzle)=100%

Initial

velocity of steam (v1)=50m/s

To Find:-

Discharge

velocity (v2)

Solution:-

From

steam table, For 10 bar, 250°c, h1=2943 KJ/kg s1=6.926

KJ/kgk

From

steam table, For 1.2 bar,

hf2

=439.3 KJ/kg ; hfg2=2244.1

KJ/kg;

sf2=1.3

61 KJ/kg K ; sfg2=5.937

KJ/kgK.

Since

s1=s2,

S1=sf

2+x2sfg2

6.926=1.361+x2(5.937)

X2=0

.9373

We

know that,

h2=hf2+x2hfg2

=

439.3+(0.9373)2244.1

h2

= 2542KJ/Kg

Exit

velocity (V2) = Rt[(2000(2943) 2542) + 502]

=

896.91m/s.

2. Dry

saturated steam at 6.5 bar with negligible velocity expands isentropically in a

convergent divergent nozzle to 1.4 bar and dryness fraction 0.956. De termine

the final velocity of steam from th e nozzle if 13% heat is loss in friction.

Find th e % reduction in the final velocity.

Given data:

Exit

pressure (P2) = 1.4 bar

Dryness

fract ion (X2) = 0.956

Heat

loss = 13%

To Find:

The

percent reduction in final velocity

Solution:

From steam table for initial

pressure P1 = 6.5bar, take values h1 =

h1

= 2758.8KJ/Kg

Similarly,

at 1.4 bar,

hfg2

= 2231.9 KJ/Kg

hf2

= 458.4KJ/Kg

h2

= hf2 + X2 hfg2

=

458.4 + (0.956) 2231.6

h2

= 2592.1 KJ/Kg

Final

velocit y (V2) = Rt (2000(h1-h2) )

V2

= 577.39 m/s

Heat

drop is 13%= 0.13

Nozzle

efficiency (η) = 1- 0.13 = 0.87

Velocity

of s team by considering the nozzle efficiency,

y

(V2) = Rt (2000(h1-h2) ) x η

V2 = 538.55 m/s

= % reductio n in final

velocity = 6.72%

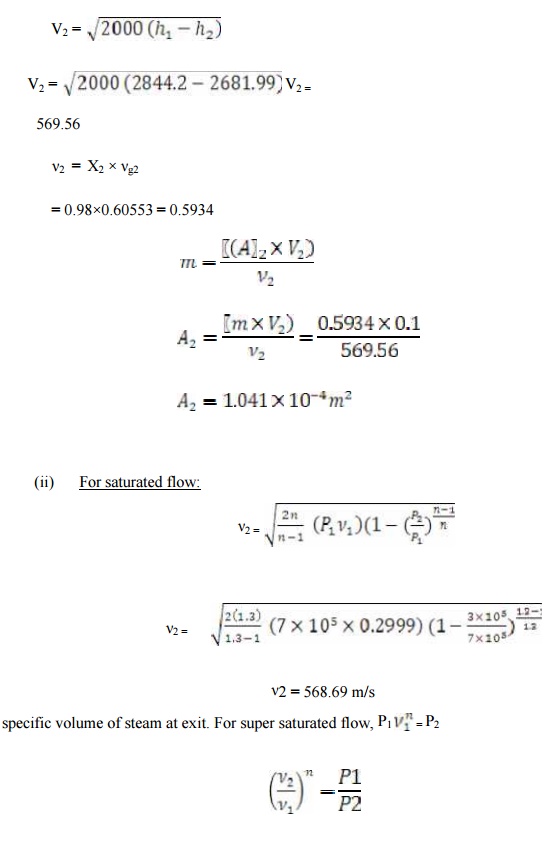

3.A

convergent divergent nozzle

receives steam at

7bar and 200oc and

it expands isentropically into a space of 3bar

neglecting the inlet velocity calculat e the exit area required for a mass flow

of 0.1Kg/sec . when the flow is in equilibrium through all and super saturated

with PV1.3=C.

Given

Data:

Initiall

pressure (P1) = 7bar = 7× 105N/m2

Initiall

temperature (T1) = 200oC

Press

ure (P2) = 3bar = 3× 105N/m2

Mass

flow rate (m) = 0.1Kg/sec

PV1.3

=C

To

Find:

Exit

area

Solution:

From

st eam table for P1 = 7bar and T1 = 200oC V1 =

0.2999

h1

= 2844.2

S1

= 6.886

Similarly

for P2 = 3bar

Vf2

= 0.001074 Vg2 = 0.60553 hf2 =

561.5

hfg2 = 2163.2

Sf2

= 1.672 Sfg2 = 5.319

We know that, S1 = S2 = St

S1

= Sf2 + X2 Sfg2

6.886

= 1.672 + X2 (5.319) X2 =

0.98

Similarly,

h2

= hf2 + X2 hfg2

h2

= 561.5 + 0.98 (2163.2)

(i)

Flow is in equilibriu m through all:

V2=569.56

ν2 = X2

×

νg2

=

0.98× 0.60553 = 0.5934

TECHNICAL

TERMS

1.Diaphragm - Partitions b etween pressure stages in a

turbine's casing.

2. Radial - flow turbine - st eam flows

outward from the shaft to the casing.

3. Radial clearance - cleara nce at the

tips of the rotor and casing.

4. Axial clearance - the fore -and-aft clearance,

at the sides of the rotor and t he casing.

5. balance piston - Instead of piston,

seal strips are also used to duplicate a piston's counter force.

6. steam rate - The steam rate is the

pounds of steam that must be supplied per kilowatt-hour of generator output at

the steam turbine inlet.

7. extraction turbine

- ste am is

withdrawn from one

or more stages,

at one or

more pressures, for heating, pl

ant process, or feedwater heater needs.

8. Wet steam: The steam w hich contains some

water particles in superposition.

9. Dry steam / dry saturated steam: When

whole mass of steam is converted into steam then it is called as dry steam.

10. Super heated steam: When the dry

steam is further heated at consta nt pressure, the temperature increases the

above saturation temperature. The steam has obtained is called super heated

stea m.

11. Degree of super heat: The difference

between the temperature of saturated steam and saturated temperature is c alled

degree of superheat.

12. Nozzle:It is a duct of varying cross

sectional area in which the velocity increases with the corresponding drop in

pressure.

13. Coefficient of nozzle: It is the

ratio of actual enthalpy drop to isentropic enthalpy drop.

14. Critical pressure ratio: There is only one value of ratio (P2/P1)

which produces maximum discharge fro m

the nozzle . then the ratio is called critica l pressure ratio.

15. Degree of reaction: It is defined as the ratio of isentropic heat drop

in th e moving blade to isentrpic heat

drop in the entire stages of the reaction turbine.

16. Compounding: It is the method of

absorbing the jet velocity in stages when the steam flows over moving blades.

(i)Velocity compounding (ii)Pressure compounding and (iii) Velocity-pressure compounding

17. Enthalpy: It is the combination of

the internal energy and the flow energy.

18. Entropy: It is the function of

quantity of heat with respective to the temperature.

19. Convergent nozzle: The crossectional

area of the duct decreases from inlet to the outlet side then it is called as

convergent nozzle.

20. Divergent nozzle: The crossectional

area of the duct increases from inlet to the outlet then it is called as

divergent nozzle.

Related Topics