Chapter: Mechanical and Electrical : Thermal Engineering : Steam Nozzles and Turbines

Steam Nozzles

STEAM NOZZLE

Introduction

A steam turbine converts the energy of high-pressure, high temperature steam produced by a steam generator into shaft work. The energy conversion is brought about in the following ways:

1. The high-pressure, high-temperature steam first expands in the nozzles emanates as a high velocity fluid stream.

2. The high velocity steam coming out of the nozzles impinges on the blades mounted on a wheel. The fluid stream suffers a loss of momentum while flowing past the blades that is absorbed by the rotating wheel entailing production of torque.

3. The moving blades move as a result of the impulse of steam (caused by the change of momentum) and also as a result of expansion and acceleration of the steam relative to them. In other words they also act as the nozzles.

Flow Through Nozzles

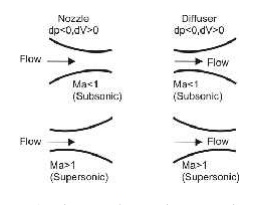

Ø A nozzle is a duct that increases the velocity of the flowing fluid at the expense of pressure drop.

Ø A duct which decreases the velocity of a fluid and causes a corresponding increase in pressure is a diffuser .

Ø The same duct may be either a nozzle or a diffuser depending upon the end conditions across it. If the cross-section of a duct decreases gradually from inlet to exit, the duct is said to be convergent.

Ø Conversely if the cross section increases gradually from the inlet to exit, the duct is said to be divergent.

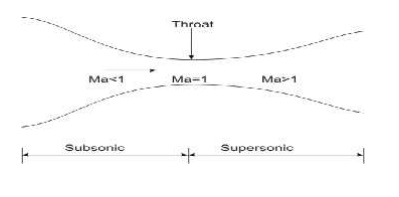

Ø If the cross-section initially decreases and then increases, the duct is called a convergent-divergent nozzle.

Ø The minimum cross-section of such ducts is known as throat.

Ø A fluid is said to be compressible if its density changes with the change in pressure brought about by the flow.

Ø If the density does not changes or changes very little, the fluid is said to be incompressible. Usually the gases and vapors are compressible, whereas liquids are incompressible .

Shapes of nozzles

1. At subsonic speeds (Ma<1) a decrease in area increases the speed of flow.

2. In supersonic flows (Ma>1), the effect of area changes are different.

Convergent divergent nozzles

SIGNIFICANCE OF STEAM TURBINES

Ø Large scale electrical energy production largely depends on the use of turbines. Nearly all of the world's power that is supplied to a major grid is produced by turbines.

Ø From steam turbines used at coal-burning electricity plants to liquid water turbines used at hydro-electric plants, turbines are versatile and can be used in a number of applications.

Ø There are also gas turbines that combust natural gas or diesel fuel for use in remote locations or where a large backup power supply is required. Most power plants use turbines to produce energy by burning coal or natural gas.

Ø The heat produced from combustion is used to heat water in boiler. The liquid water is converted to steam upon heating and is exhausted through a pipe which feeds the steam to the turbine.

Ø The pressurized steam flow imparts energy on the blades and shaft of the turbine causing it to rotate.

Ø The rotational mechanical energy is then converted to electrical energy using a generator.

Related Topics