Chapter: Modern Analytical Chemistry: Calibrations, Standardizations, and Blank Corrections

Standardizing Methods: Internal Standards

Internal Standards

The successful application of an external standardization or the

method of standard additions, depends

on the analyst’s ability to handle samples

and standards repro- ducibly. When a procedure cannot be controlled to the extent

that all samples

and standards are treated

equally, the accuracy and precision of the standardization may suffer. For example,

if an analyte is present

in a volatile solvent, its concentration

will increase if some solvent

is lost to evaporation. Suppose

that you have a sample and a standard with identical concentrations of analyte and identical signals.

If both experience the same loss of solvent

their concentrations of analyte and signals will continue to be identical. In effect, we can ignore

changes in concentration due to evaporation provided

that the samples

and standards experience an equivalent loss of

solvent. If an identical standard

and sample experience different losses of solvent,

however, their concentrations and signals will no longer be equal. In this

case, an external standardization or standard addition results in a determinate

error.

A standardization is still possible

if the analyte’s signal is referenced to a signal generated by another species

that has been

added at a fixed concentration to all samples and standards. The added species,

which must be different from the ana- lyte, is called an internal

standard.

Since the analyte

and internal standard

in any sample or standard

receive the same treatment, the ratio of their signals

will be unaffected by any lack

of repro- ducibility in the procedure. If a solution

contains an analyte

of concentration CA,

and an internal standard of concentration, CIS, then the signals

due to the analyte, SA, and the internal standard, SIS, are

where kA and kIS are the sensitivities for the analyte

and internal standard,

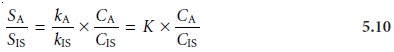

respectively. Taking the ratio of the two signals gives

Because equation 5.10

is defined in terms of a ratio,

K, of the analyte’s sensitivity and the internal

standard’s sensitivity, it is not necessary to independently deter- mine values for either

kA or kIS.

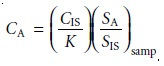

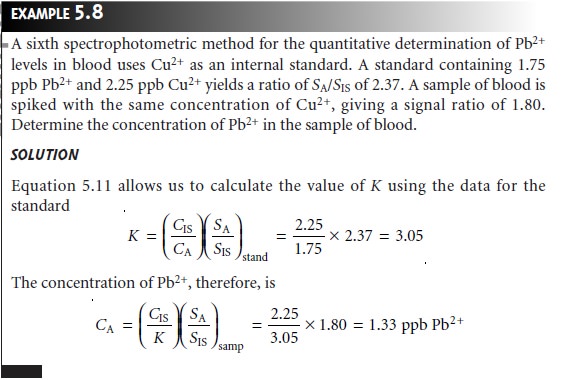

In a single-point internal standardization, a single standard is

prepared, and K is determined by solving equation 5.10

A single-point internal

standardization has the same limitations as a single-

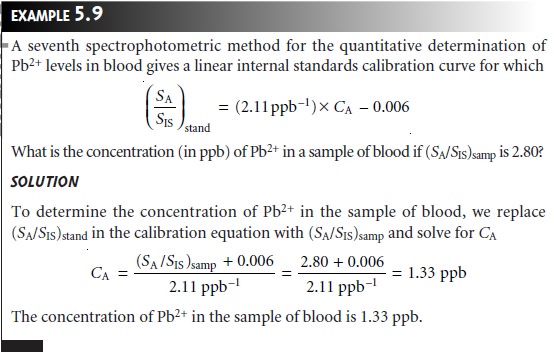

point normal calibration. To construct an internal standard

calibration curve, it is

necessary to prepare several standards containing different concentrations of ana- lyte. These

standards are usually

prepared such that the internal

standard’s concen- tration is constant. Under

these conditions a calibration curve

of (SA/SIS)stand versus CA is linear with a slope of K/CIS.

When the internal

standard’s concentration cannot

be held constant

the data must be

plotted as (SA/SIS)stand versus CA/CIS, giving a linear calibration curve with a slope

of K.

Related Topics