Chapter: Modern Analytical Chemistry: Calibrations, Standardizations, and Blank Corrections

Linear Regression and Calibration Curves

Linear Regression

and Calibration Curves

In a single-point external standardization, we first determine

the value of k by

measuring the signal for a single standard

containing a known

concentration of analyte. This value of k and the signal for the sample

are then used to calculate the concentration of analyte

in the sample (see Example

5.2). With only a single

determination of k, a

quantitative analysis using a single-point external stan- dardization is straightforward. This is also true for a single-point standard addi- tion (see

Examples 5.4 and

5.5) and a single-point internal standardization (see

Example 5.8).

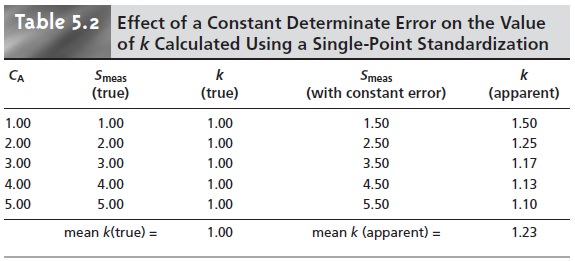

A multiple-point standardization presents a more

difficult problem. Consider the data in Table 5.1 for a multiple-point external

standardiza- tion. What is the best estimate of the relationship

between Smeas and CS? It is tempting to treat

this data as five separate single-point standardizations, determining k for each stan- dard and reporting the mean value.

Despite its simplicity, single-point

standardizations, determining k for

each stan dard and reporting the mean value.

Despite its simplicity, this is not an appropriate

way to treat a multiple-point standardization.

In a single-point standardization, we assume that the reagent

blank (the first

row in Table

5.1) corrects for

all constant sources of determinate error. If this is not the case, then the

value of k determined by a single- point standardization will have a determinate error.

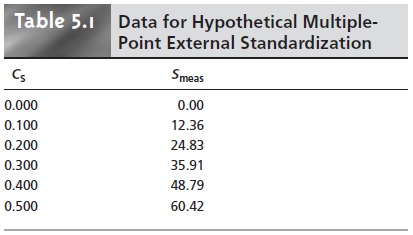

Table 5.2 demonstrates how an uncorrected constant error affects

our determination of k. The first

three columns show the

concentration of analyte,

the true measured

signal (no constant error)

and the true

value of k for

five standards. As expected, the value of k is the same for each standard. In the fourth column a constant determinate error of +0.50 has been

added to the measured signals. The corresponding val- ues

of k are shown

in the last column. Note that a different

value of k is obtained for

each standard and

that all values

are greater than the

true value. As we noted,

this is a significant limitation to any single-point standardization.

How do we find the best estimate

for the relationship be- tween the measured signal and the

concentration of analyte

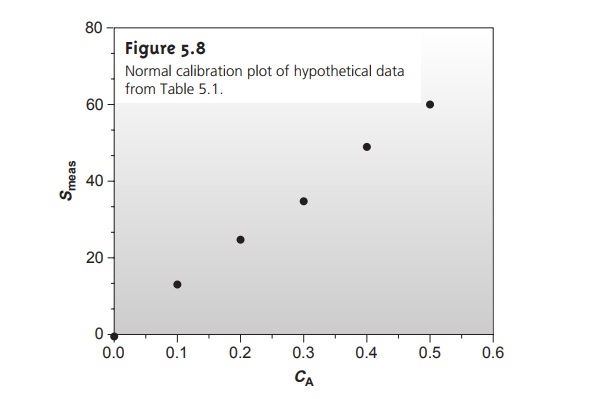

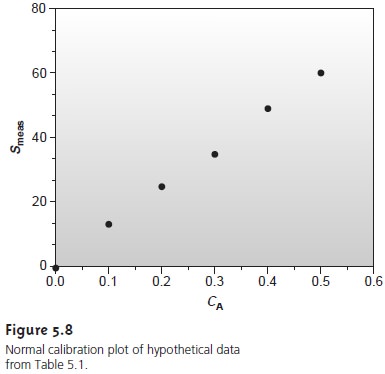

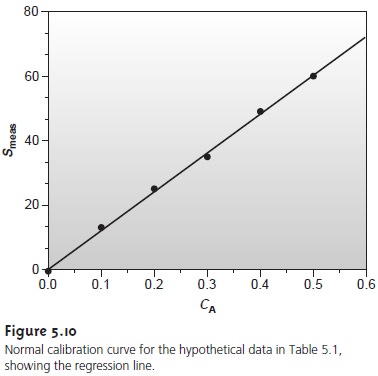

in a multiple-point standardization? Figure 5.8 shows

the data in Table

5.1 plotted as a normal calibration curve. Although the data

appear to fall along a straight line,

the actual calibration curve is not intuitively obvious. The process

of mathemati- cally determining the best equation for the calibration curve is called regression.

Linear Regression of Straight-Line Calibration Curves

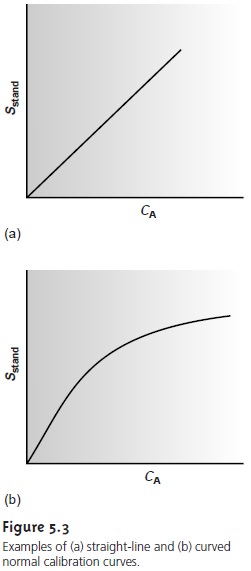

A calibration curve shows us the relationship between the measured

signal and the analyte’s concentration in a series of standards. The most useful

calibration curve is a straight line since the method’s sensitivity is the same for all concentrations of an-

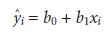

alyte. The equation for a linear calibration curve is

y = β0 + β1x

….5.12

where y is the signal and x is the amount of analyte. The constants β0 and β1 are the

true y-intercept and the true slope,

respectively. The goal of linear regres- sion is to determine the best estimates for the slope,

b1, and

y-intercept, b0. This is

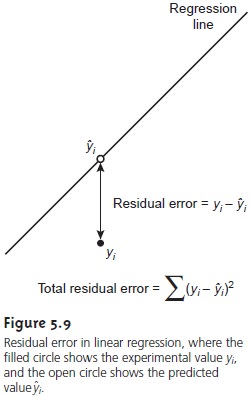

accomplished by minimizing the residual

error between the experimental val- ues, yi, and those values,

yˆi, predicted by equation 5.12 (Figure 5.9).

For obvious reasons, a regression analysis

is also called a least-squares treatment. Several ap- proaches to the linear

regression of equation 5.12 are discussed in the following sections.

Unweighted Linear Regression with Errors in y

The most commonly

used form of linear regression is based on three assump- tions: (1) that any difference between

the experimental data and the calculated

regression line is due to indeterminate errors affecting the values of y, (2) that these indeterminate errors are

normally distributed, and

(3) that the

indetermi- nate errors in y do not depend on the value

of x. Because we assume that indeter-

minate errors are the same for all standards, each standard contributes equally in

estimating the slope

and y-intercept. For this reason the result is considered an unweighted linear regression.

The second assumption is generally true because of the central

limit theorem. The validity of the two remaining assumptions is less cer- tain and should be evaluated before

accepting the results

of a linear regression.

In particular, the

first assumption is always suspect

since there will

certainly be some indeterminate errors affecting the values of x. In preparing

a calibration curve, however, it is not

unusual for the

relative standard deviation of the mea- sured signal (y) to be significantly larger

than that for

the concentration of ana-

lyte in the standards (x). In such circumstances, the first assumption is usually

reasonable.

Finding the Estimated Slope and y-Intercept

The derivation of equations for cal-

culating the estimated slope and y-intercept can be found

in standard statistical texts7 and is not developed here. The resulting equation for the slope is given as

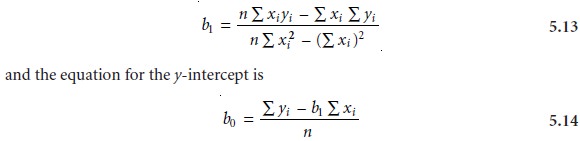

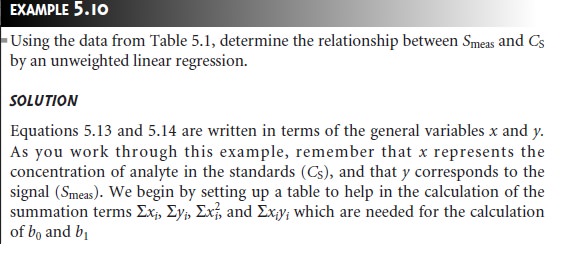

Although equations 5.13 and 5.14 appear formidable, it is only necessary to evaluate

four summation terms.

In addition, many

calculators, spreadsheets, and

other com- puter software packages are capable

of performing a linear regression analysis based on this

model. To save

time and to avoid tedious

calculations, learn how

to use one of

these tools. For

illustrative purposes, the

necessary calculations are

shown in de- tail in the following

example.

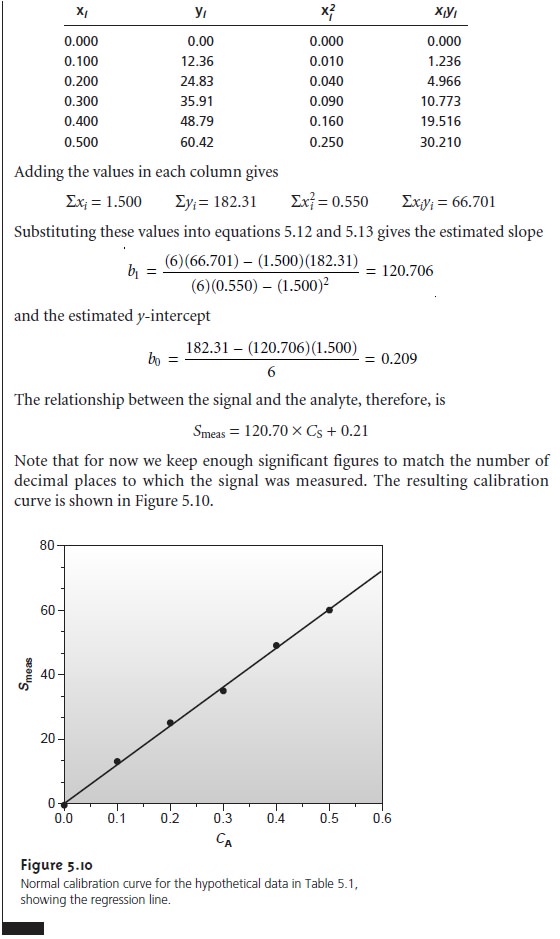

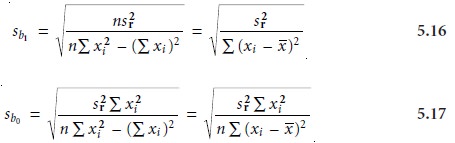

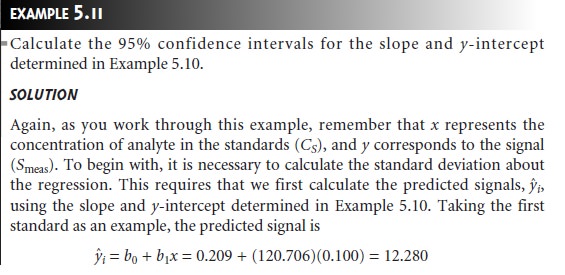

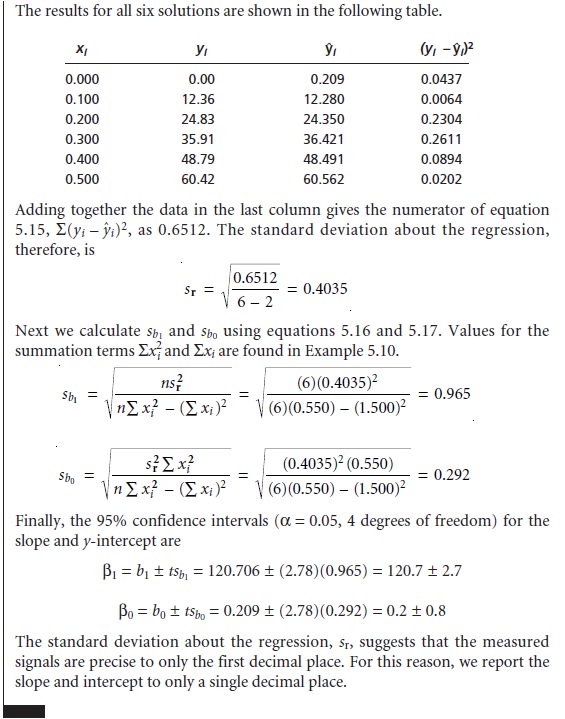

Uncertainty in the Regression Analysis

As shown in Figure 5.10, the regression line need not pass through the data points (this is the consequence of indeter- minate errors affecting the signal). The cumulative deviation of the data from the regression line is used to calculate the uncertainty in the regression due to indeterminate error.

This is called the standard deviation about the regression, sr,

and is given as

There is an obvious similarity between equation 5.15,

except that the sum of squares term for sr is determined rela- tive

to yˆi

instead of yˆ, and the denominator is n – 2 instead of n – 1; n – 2 indicates

that the linear

regression analysis has only n –

2 degrees of freedom since

two pa- rameters, the slope and the intercept, are used to calculate the values of yˆi.

A more useful

representation of uncertainty is to consider

the effect of indeter-

minate errors on the predicted slope and intercept. The standard deviation of the slope and intercept are given as

where t is selected

for a significance level of α and for n –

2 degrees of freedom. Note that the terms tsb1 and tsb0 do not contain a factor of (Root of n

)–1 because the con-fidence interval is based on a single

regression line. Again, many calculators, spread- sheets, and computer

software packages can handle the calculation of sb0 and

sb1 and the corresponding confidence intervals

for β0 and β1. Example

5.11 illustrates the calculations.

To minimize the uncertainty in the predicted slope and y-intercept, calibration curves are best prepared

by selecting standards that are evenly

spaced over a wide

range of concentrations or amounts

of analyte. The reason for this can be rational- ized by examining equations 5.16 and 5.17.

For example, both

sb0 and sb1 can be minimized by increasing the value of the term Σ(xi –

x ‘ )2, which

is present in the de-

|

i |

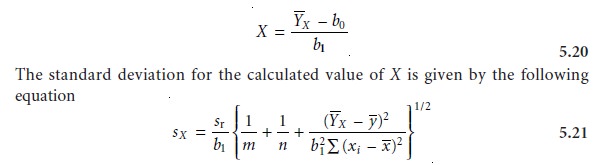

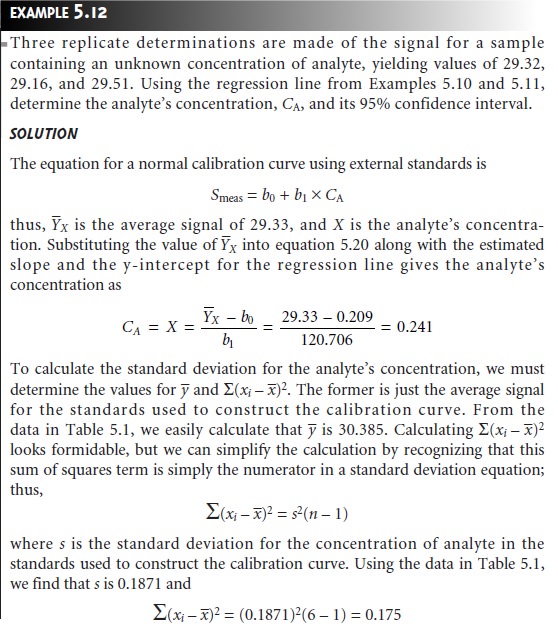

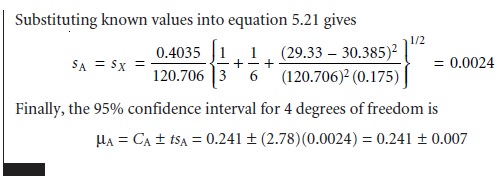

Using the Regression Equation

Once the regression equation is known,

we can use it

to determine the concentration of analyte in a sample.

When using a normal cali- bration curve with external

standards or an internal standards calibration curve, we

|

YX |

where m is the number of replicate samples

used to establish Y’X, n is

the number of calibration standards, yˆ is

the average signal for the standards, and xi and–x’ are

the individual and mean concentrations of the standards. Once sX is

known the confi- dence interval for the analyte’s concentration can be calculated as

μX= X ± tsX

where μX is the expected

value of X in

the absence of determinate errors,

and the value of t is determined by the desired

level of confidence and for n –

2 degrees of freedom. The following example

illustrates the use

of these equations for an analysis using a normal calibration curve with external

standards.

In a standard addition the analyte’s concentration is determined

by extrapolating the calibration curve to find the x-intercept. In this case

the value of X is

where n is the number of standards used in preparing

the standard additions

cali- bration curve (including the sample with no added

standard), and –y is

the average signal for the

n

standards. Because the

analyte’s concentration is determined by ex-

trapolation, rather than by interpolation, sX

for the method of standard additions

generally is larger than for

a normal calibration curve.

A linear regression analysis should not

be accepted without

evaluating the validity of the model

on which the

calculations were based.

Perhaps the simplest way to evaluate

a regression analysis

is to calculate and plot the residual error for each

value of x. The

residual error for

a single calibration standard, ri, is given as

ri = yi – yˆi

If the regression model is valid,

then the residual

errors should be randomly distrib- uted about an average

residual error of 0, with

no apparent trend

toward either smaller or larger residual

errors (Figure 5.11a).

Trends such as those shown

in Fig- ures 5.11b

and 5.11c provide

evidence that at least one of the assumptions on which

the regression model

is based are incorrect. For example, the trend toward

larger residual errors in Figure 5.11b

suggests that the

indeterminate errors affecting y are not independent of the value

of x. In Figure

5.11c the residual errors are not

ran- domly distributed, suggesting that the data cannot be modeled with a straight-line relationship. Regression methods for these two cases are discussed

in the following sections.

Weighted Linear Regression with Errors in y

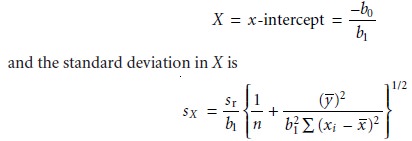

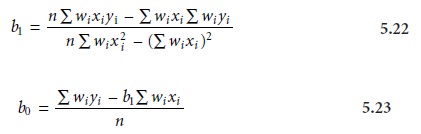

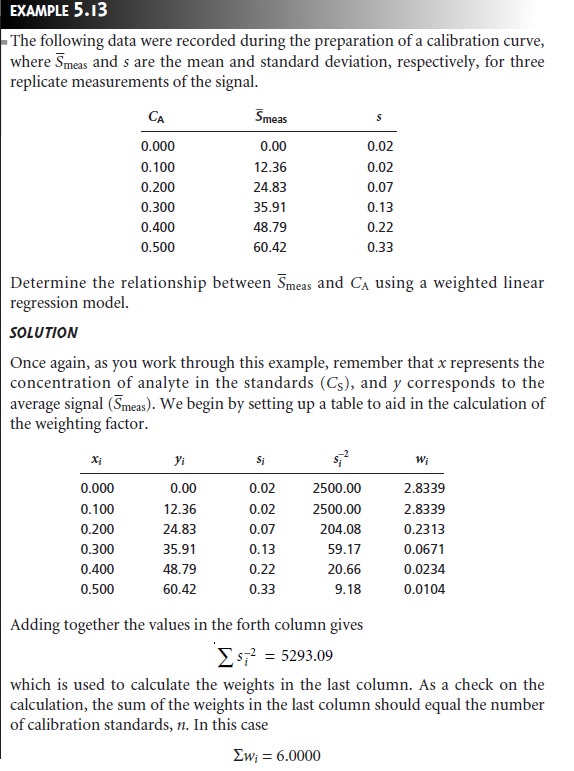

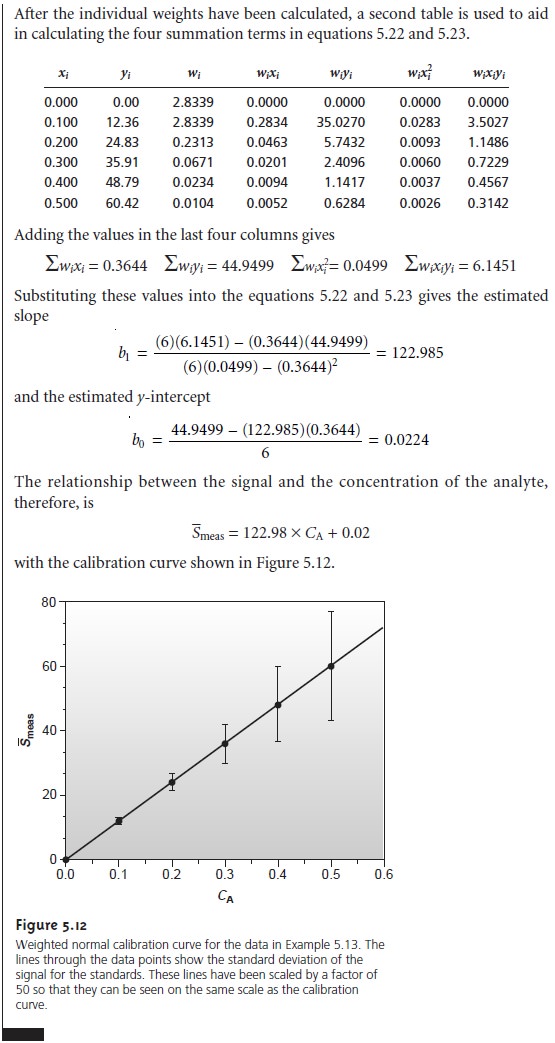

Equations 5.13 for the slope, b1, and 5.14 for the y-intercept, b0, assume that

indeterminate errors equally

affect each value

of y. When this

assumption is false,

as shown in Figure 5.11b, the variance associated with each value of y must be included

when estimating β0 and β1. In this case the predicted slope and intercept are

where wi is

a weighting factor accounting for the variance in measuring yi. Values of

wi are calculated using equation 5.24

where si is the standard deviation associated with

yi. The

use of a weighting factor ensures that the contribution of each pair of xy values to the regression line is proportional to the precision with which yi is

measured.

Equations for calculating confidence intervals for the slope, the

y-intercept, and the concentration of analyte when using a weighted

linear regression are not as easily defined

as for an unweighted

linear regression.

The confidence in- terval for the concentration of an analyte, however, will be at its optimum

valuewhen the analyte’s

signal is near the weighted centroid, –y, of the calibration curve

Weighted Linear Regression with Errors in Both x and y

If we remove

the assumption that the indeterminate errors affecting a calibration

curve are found only in the signal (y), then indeterminate errors affecting the preparation of standards containing known amounts of analyte (x) must

be fac- tored into

the regression model.

The solution for

the resulting regression line is

computationally more involved than that for

either the unweighted or weighted

regression lines, and is not presented in this text.

Curvilinear and Multivariate Regression

Regression models based on a straight line, despite their apparent complexity, use the simplest functional relationship between two variables. In many cases,

calibra- tion curves show a pronounced curvature at high concentrations of analyte (see Figure 5.3b). One approach to constructing a calibration curve

when curvature exists

is to seek a transformation function

that will make the data linear. Logarithms, expo- nentials, reciprocals, square

roots, and trigonometric functions have all been used in

this capacity. A plot of y versus log x is a typical example.

Such transformations are not

without complications. Perhaps

the most obvious

is that data

that originally has a uniform variance for the y values will not maintain that uniform variance when the variable is transformed.

A more rigorous

approach to developing a regression model

for a nonlinear calibration curve is to fit

a polynomial equation such as y =

a

+ bx + cx2 to the data.

Equations for calculating the parameters a, b, and c are

derived in the

same manner as that described earlier

for the straight-line model. When a single

polynomial equation cannot be fitted to the calibration data, it may be possible

to fit separate polynomial equations to short segments

of the calibration curve. The result is a sin- gle

continuous calibration curve

known as a spline function.

The regression models considered earlier

apply only to functions containing a single independent variable. Analytical methods, however, are frequently subject

to determinate sources of error due to interferents that contribute to the measured

sig- nal. In the

presence of a single interferent, equations 5.1 and

5.2 become

Smeas = kAnA + kInI + Sreag

Smeas = kACA + kICI + Sreag

where kI is the interferent’s sensitivity, nI is the moles

of interferent, and

CI is the in- terferent’s concentration.

Multivariate calibration curves can be prepared using standards that contain known

amounts of analyte

and interferent.

Related Topics