Chapter: Mechanical : Design of Transmission Systems : Spur Gears and Parallel Axis Helical Gears

Spur Gears and Parallel Axis Helical Gears

SPUR GEARS AND PARALLEL

AXIS HELICAL GEARS

Gear Terminology

The following terms, which will be mostly used in this chapter, should

be clearly understood at this stage.

1. Pitch circle. It is an imaginary circle which

by pure rolling action, would give the same

motion as the actual gear

2. Pitch circle diameter. It is

the diameter of the pitch circle. The size of the gear is usually specified by the pitch circle

diameter. It is also called as pitch diameter.

3. Pitch point. It is a common point of contact

between two pitch circles.

4. Pitch surface. It is the surface of the

rolling discs which the meshing gears have replaced at the pitch circle.

5. Pressure angle or angle of obliquity. It is

the angle between the common normal to two

gear teeth

at the point of contact and the common tangent at the pitch point. It is

usually denoted by φ. The standard pressure angles are 1 14 /2° and 20°.

6. Addendum. It is the radial distance of a

tooth from the pitch circle to the top of the tooth.

7. Dedendum. It is the radial distance of a

tooth from the pitch circle to the bottom of the tooth.

8. Addendum circle. It is the circle drawn through

the top of the teeth and is concentric with

the pitch circle.

9. Dedendum circle. It is the circle drawn

through the bottom of the teeth. It is also called

root

circle.

Note : Root

circle diameter = Pitch circle diameter × cos φ, where φ is the

pressure angle.

10. Circular pitch. It is the distance

measured on the circumference of the pitch circle from a point of one tooth to the

corresponding point on the next tooth. It is usually denoted by pc.

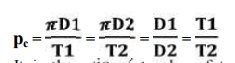

Mathematically,

Circular

pitch, pc = π D/T

Where, D = Diameter of the pitch circle, and

T = Number of teeth on the wheel.

A little consideration will show that the two gears will mesh together

correctly, if the

two

wheels have the same circular pitch.

Note : If

D1 and D2 are the diameters of the two meshing gears having the teeth T1 and T2

respectively; then for them to mesh correctly,

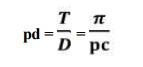

11.Diametral

pitch. It is the ratio of number of teeth to the pitch circle diameter in

millimetres. It denoted by pd. Mathematically,

Diametral

pitch,

where T

= Number of teeth, and

D

= Pitch circle diameter.

12. Module. It is the ratio of the pitch

circle diameter in millimetres to the number of teeth. It is usually denoted by

m. Mathematically,

Module, m = D / T

Note : The recommended series of

modules in Indian Standard are 1, 1.25, 1.5, 2, 2.5, 3, 4, 5, 6, 8, 10, 12, 16, 20, 25, 32, 40 and

50.

The

modules 1.125, 1.375, 1.75, 2.25, 2.75, 3.5, 4.5,5.5, 7, 9, 11, 14, 18, 22, 28,

36 and 45 are of second choice.

13.

Clearance. It is

the radial distance from the top of the tooth to the bottom of the tooth, in a meshing gear. A circle passing

through the top of the meshing gear is known as clearance circle.

14.

Total

depth. It is the radial distance between the addendum and the dedendum circle

of a gear. It is equal to the sum of

the addendum and dedendum.

15.Working depth. It is radial distance from the

addendum circle to the clearance circle. It

is equal to the sum of the addendum of the two meshing gears.

16.

Tooth

thickness. It is the width of the tooth measured along the pitch circle.

17.Tooth space. It is the width of space between

the two adjacent teeth measured along the

pitch circle.

18. Backlash. It is the difference between

the tooth space and the tooth thickness, as

measured on the pitch circle.

19.

Face of

the tooth. It is surface of the tooth above the pitch surface.

20.

Top land. It is

the surface of the top of the tooth.

21.

Flank of

the tooth. It is the surface of the tooth below the pitch surface.

22.Face width. It is the width of the gear

tooth measured parallel to its axis.

23.

Profile. It is

the curve formed by the face and flank of the tooth.

24.

Fillet

radius. It is the radius that connects the root circle to the profile of the

tooth.

25. Path of contact. It is the path traced by the

point of contact of two teeth from the beginning

to the end of engagement.

26. Length of the path of contact. It is

the length of the common normal cut-off by the addendum circles of the wheel and pinion.

27.Arc of contact. It is the path traced by a

point on the pitch circle from the beginning to the end of engagement of a given pair of teeth. The arc of contact

consists of two parts, i.e.

(a) Arc of approach. It is the portion of

the path of contact from the beginning of the engagement

to the

pitch point.

(b) Arc of recess. It is the portion of the

path of contact from the pitch point to the end of the engagement of a pair of

teeth.

Note: The ratio of the length of arc

of contact to the circular pitch is known as contact ratio i.e. number of pairs of teeth in contact.

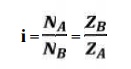

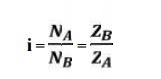

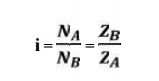

Speed ratios and number of

teeth

It is the

ratio of speed of driving gear to the speed of the driven gear.

where, NA and NB

= speed of the driver and driven respectively, and ZA and ZB

= Number of teeth on driver and driven respectively.

Force analysis

1. Tangential component:

The tangential component Ft is a useful component. Because it

transmit power. Using the value of Ft , the magnitude of torque and

transmitted power can be determined.

Transmitted power Wt = Ft

2. Radial component:

The radial component Fr is a separating force which is always

directed towards the centre of the gear. Fr does not really a useful

component. It is also called as transverse force or bending force.

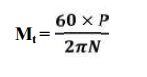

Let P =

Power transmitted (W)

Mt = Torque transmitted (N-m)

N1

and N2 = Speed of pinion and

gear respectively

d1

and d2 =

Pitch circle diameters of pinion and gear respectively

ϕ = Pressure angle.

The

torque transmitted by gear

DESIGN PROCEDURE FOR SPUR GEAR:

1.

Calculation

of gear ratio (i):

where, NA and NB

= speed of the driver and driven respectively, and ZA and ZB

= Number of teeth on driver and driven respectively.

2. Selection

of material

Consulting Table 5.3, knowing the gear ratio i,

choose the suitable material.

3. If not

given, assume gear life (say 20000 hrs)

4.

Calculation

of initial design torque:

[Mt] = Mt . K. Kd

where, [Mt] = transmission torque

K = Load

factor, Table 5.11

Kd =

Dynamic load factor, Table 5.12

Assume K. Kd = 1.3 ( if not given)

5.

Calculation

of Eeq, [ϭb] and [ϭc]:

ü From

table 5.20 Calculate Eeq

ü From

table 5.16 Calculate Design bending stress

[ϭb]

ü Calculate

Design contact stress [ϭc] by

[ϭc] = CB . HB. Kcl (or)

[ϭc] = CR . HRC. Kcl

where, CB

CR = Coefficient of surface hardness from table 5.18

HB HRC = Hardness number

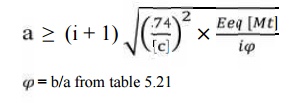

6.

Calculation

if centre distance (a):

6.

Select

number of teeth on gear and pinion:

Ø On

pinion,Z1 = Assume 18

Ø On gear, Z2 = i X Z1

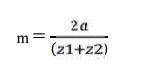

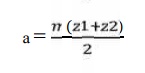

8. Calculation of module:

Choose standard module from table 5.8

9. Revision

of centre distance(m)

10. Calculate

b, d1, v and ѱp :

Calculate

face width, b = ѱ. a

Calculate

pitch dia, d = m.z1

Calculate pitch

line velocity, v = (πd1N1)/60

Calculate

value of ѱp = b/d1

11.

Selection of quality of gear:

Knowing the pitch line velocity and consulting

table 5.22, select a suitable quality

of gear.

12.

Revision of design torque [Mt]: Revise K:

Using the calculated value of ѱp revise

the K value by using table 5.11

Revise Kd:

Using the selected quality if gear and pitch line

velocity, revise the Kd

value

[Mt] = Mt . K. Kd

13. Check

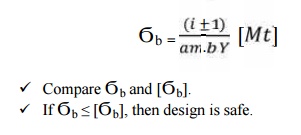

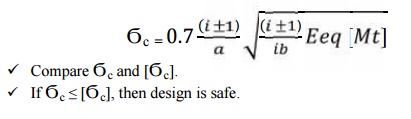

for bending:

14. Check

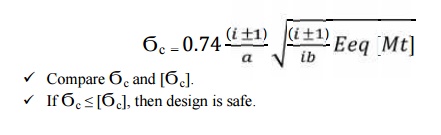

for wear strength:

Calculate induced contact stress,

15. If the design is not satisfactory (ϭb

> [ϭb] and / or ϭc > [ϭc] ), then

increase the module of face width value of the gear material.

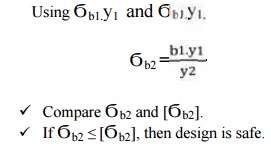

16. Check

for gear:

a.

Check for

bending:

If Ϭb2 ≤ [Ϭb2], then design

is safe.

b. Check

for wear strength:

Calculate induced contact stress will be same for

pinion and gear,

So,

Ϭc2 = Ϭc

ü Compare Ϭc

and [Ϭc]

ü If Ϭc

≤ [Ϭc], then design is safe

DESIGN

PROCEDURE FOR HELICAL GEAR:

1. Calculation of gear ratio (i):

where, NA and NB

= speed of the driver and driven respectively, and ZA and ZB

= Number of teeth on driver and driven respectively.

2. Selection

of material

Consulting Table 5.3, knowing the gear ratio i,

choose the suitable material.

3. If not

given, assume gear life (say 20000 hrs)

4.

Calculation

of initial design torque:

[Mt] = Mt . K. Kd

where, [Mt] = transmission torque

K = Load

factor, Table 5.11

Kd =

Dynamic load factor, Table 5.12

Assume K. Kd = 1.3 ( if not given)

5.

Calculation

of Eeq, [ϭb] and [ϭc]:

ü From

table 5.20 Calculate Eeq

ü From

table 5.16 Calculate Design bending stress

[ϭb]

ü Calculate

Design contact stress [ϭc] by

[ϭc] = CB . HB. Kcl (or)

[ϭc] = CR . HRC. Kcl

CB CR = Coefficient of

surface hardness from table 5.18

HB HRC = Hardness number

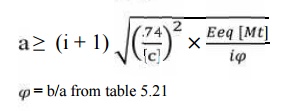

6.

Calculation

if centre distance (a):

7.Select number of teeth on gear and pinion:

Ø On

pinion,Z1 = Assume ≥ 17

Ø On gear, Z2 = i X Z1

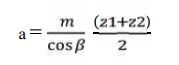

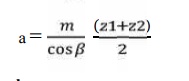

8. Calculation

of module:

Choose standard module from table 5.8

9. Revision

of centre distance (m):

10. Calculate

b, d1, v and ѱp :

Calculate

face width, b = ѱ. a

Calculate

pitch dia, d = (mn.z1)/ cos β

Calculate

pitch line velocity, v = (πd1N1)/60

Calculate

value of ѱp = b/d1

11. Selection

of quality of gear:

Knowing the pitch line velocity and acosulting

table 5.22, select a suitable quality

of gear.

12.

Revision of design torque [Mt]: Revise K:

Using the calculated value of ѱp revise

the K value by using table 5.11

Revise Kd:

Using the selected quality if gear and pitch line

velocity, revise the Kd

value

[Mt] = Mt . K. Kd

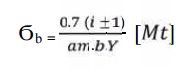

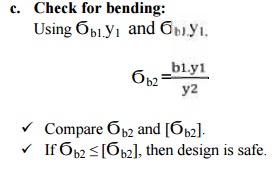

13. Check

for bending:

Compare Ϭb

and [Ϭb].

If Ϭb ≤ [Ϭb], then design is

safe.

14. Check

for wear strength:

Calculate induced contact stress,

If Ϭc ≤ [Ϭc], then design is

safe.

15. If the design is not satisfactory (ϭb > [ϭb]

and / or ϭc > [ϭc] ), then increase the module of face width value of the gear material.

16. Check

for gear:

ü Compare Ϭb2

and [Ϭb2].

ü If Ϭb2

≤ [Ϭb2], then design is safe.

d. Check for wear strength:

Calculate induced contact stress will be same for

pinion and gear,

So,

Ϭc2 = Ϭc

ü Compare Ϭc

and [Ϭc]

ü If Ϭc

≤ [Ϭc], then design is safe

SOLVED PROBLEMS

1.

The

following particulars of a single reduction spur gear are given : Gear ratio =

10 : 1; Distance between centres = 660 mm approximately; Pinion transmits 500

kW at 1800 r.p.m.; Involute teeth of standard proportions (addendum = m) with

pressure angle of 22.5°; Permissible normal pressure between teeth = 175 N per

mm of width. Find :

1. The nearest standard module if no interference is

to occur;

2. The number of teeth on each wheel;

3. The necessary width of the pinion; and

4.

The load

on the bearings of the wheels due to power transmitted.

Solution : Given :

G = TG / TP = DG / DP = 10 ;

L = 660 mm ;

P = 500 kW = 500 × 103 W;

NP = 1800 r.p.m. ; φ = 22.5° ;

WN = 175 N/mm width

1. Nearest standard module if no interference is to

occur

Let m = Required module,

TP = Number of teeth on the pinion,

TG = Number of teeth on the gear,

DP = Pitch circle diameter of the pinion, and

DG = Pitch circle diameter of the gear.

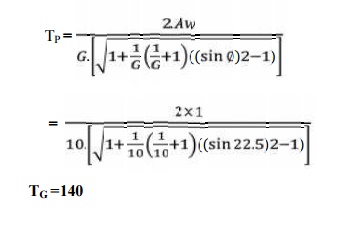

We know that minimum number of teeth on the pinion

in order to avoid interference,

we

already know that,

L = (DG / 2) + (Dp

/ 2) = 5.5 Dp

We also

know that

∴ DP

= m . TP

=

DP / TP = 120 / 14

m

= 8.6 mm

Since

the nearest standard value of the module is 8 mm, therefore we shall take

m = 8 mm

Ans.

2. Number of teeth on each wheel

We know that number of teeth on the pinion,

TP = DP / m = 120 / 8 = 15 Ans.

and number of teeth on the gear,

TG = G × TP = 10 × 15 = 150 Ans.

3. Necessary width of the pinion

We know that the torque acting on the pinion,

T = 60P/(2πN)

= 2652

N-m

Tangential load, WT = T/(DP/2)

= 2652 / (20.12 / 2)

T = 44200

N

WN = Wt/cosϕ

= 44200 / cos 22.5

W = 47

840 N

Since the

normal pressure between teeth is 175 N per mm of width, therefore necessary

width of

the

pinion,

b = 47840 / 175

=273.4 mm

Ans.

4. Load on the bearings of the wheels

We know

that the radial load on the bearings due to the power transmitted,

WR = WN . sin φ

= 47 840 ×

sin 22.5°

= 18 308 N

= 18.308 kN An

2.

A bronze

spur pinion rotating at 600 r.p.m. drives a cast iron spur gear at a

transmission ratio of 4 : 1. The allowable static stresses for the bronze

pinion and cast iron gear are 84 MPa and 105 MPa respectively. The pinion has

16 standard 20° full depth involute teeth of module 8 mm. The face width of

both the gears is 90 mm. Find the power that can be transmitted from the

standpoint of strength.

Solution.

Given :

NP = 600 r.p.m. ;

V.R. = TG / TP = 4 ;

σOP = 84 MPa = 84 N / mm2 ; σOG = 105 MPa = 105 N/mm2 ;

TP = 16 ;

m = 8 mm ;

b = 90 mm

We know

that pitch circle diameter of the pinion,

DP

= m.TP = 8 × 16 = 128 mm = 0.128 m

velocity,

∴ Pitch line

v

= πDN/60

=

4.02 m/s

We know

that for 20° full depth involute teeth, tooth form factor for the pinion,

yP = 0.154 – (.912/ Tp)

= 0.097

and tooth form factor for the gear

yG = 0.154 – (.912/ TG)

= 0.14

σOP × yP = 84 × 0.097 = 8.148

and σOG × yG = 105 × 0.14 = 14.7

Since

(σOP × yP) is less than ( σOG × yG), therefore the pinion is weaker. Now using

the Lewis equation for the pinion, we have tangential load on the tooth (or

beam strength of the tooth),

WT = σwP.b.π m.yP

= (σOP × Cv) b. π m.yP (Q σWP = σOP.Cv)

= 84 × 0.427 × 90 ×

π × 8 × 0.097 = 7870 N

∴ Power that can be transmitted = WT × v

= 7870 ×

4.02

= 31 640 W

= 31.64 kW Ans.

3.

A pair of

helical gears are to transmit 15 kW. The teeth are 20° stub in diametral plane

and have a helix angle of 45°. The pinion runs at 10 000 r.p.m. and has 80 mm

pitch diameter. The gear has 320 mm pitch diameter. If the gears are made of cast

steel having allowable static strength of 100 MPa; determine a suitable module

and face

width

from static strength considerations and check the gears for wear, given σes =

618 MPa.

Solution.

Given :

P = 15 kW = 15 × 103 W;

φ = 20° ; α = 45° ;

NP = 10 000 r.p.m. ;

DP = 80 mm = 0.08 m ;

DG = 320 mm = 0.32 m ;

σOP = σOG = 100 MPa = 100 N/mm2 ; σes = 618 MPa =

618 N/mm2

Module

and face width

Let m = Module in mm, and b =

Face width in mm.

Since both the pinion and gear are made of the same material (i.e. cast

steel), therefore the pinion is weaker. Thus the design will be based upon the

pinion.

We know

that the torque transmitted by the pinion,

T = (60P) / (2πN)

= 14.32 N-m.

Tangential tooth load on the pinion,

WT

= T / (Dp/2)

We know

that number of teeth on the pinion,

TP = DP / m = 80 / m

and formative or equivalent

number of teeth for the pinion, TE = TP / cos3

α

= 226.4 / m

∴ peripheral velocity,

v = (π Dp

Np) / 60

= 42 m/s

Velocity

factor, Cv =

0.104

Since the

maximum face width (b) for helical gears may be taken as 12.5 m to 20 m, where

m is the module, therefore let us take

b = 12.5 m

We know

that the tangential tooth load (WT),

358 = (σOP . Cv) b.π m.y'P

= (100 ×

0.104) 12.5 m × π m (0.175 – 0.0037 m)

= 409 m2

(0.175 – 0.0037 m)

= 72 m2 –

1.5 m3

Solving this expression by hit

and trial method, we find that m = 2.3 say 2.5

mm Ans.

and face

width, b =

12.5 m = 12.5 × 2.5 = 31.25 say 32 mm

Ans.

Checking the gears for wear

We know

that velocity ratio,

V.R. = DG / DP

= 320 / 80

= 4

We know

that the maximum or limiting load for wear,

Ww = (D bQK) / cos2a

= 5554 N

A helical cast steel gear with 30° helix angle has

to transmit 35 kW at 1500 r.p.m. If the gear has 24 teeth, determine the

necessary module, pitch diameter and face width for 20° full depth teeth. The

static stress for cast steel may be taken as 56 MPa. The width of face may be

taken as 3 times the normal pitch. What would be the end thrust on the gear?

The tooth factor for 20° full depth involute gear may be taken as 0.154 –

0.912/T where TE represents the equivalent number of teeth.

Solution.

Given :

α = 30° ;

P = 35 kW = 35 × 103 W ;

N = 1500 r.p.m. ;

TG = 24 ;

φ = 20° ;

σo = 56 MPa = 56 N/mm2 ; b = 3 × Normal pitch = 3

pN

Module

Let m = Module in mm, and

DG = Pitch circle diameter of the gear in mm. We

know that torque transmitted by the gear,

T = (60P) / (2πN)

= 223x103 N-mm.

Formative or equivalent number of teeth,

TE = TP / cos3 α

= 37.

∴ Tooth factor, y' = 0.154 – 0.912/T

= 0.129

Tangential tooth load on the pinion,

WT

= T / (Dp/2)

∴ = 18600 / m peripheral

velocity,

v = (π Dp Np) / 60

= 1.885m

m/s

Velocity factor, Cv = 0.75 / (0.75 + v )

= 0.75 /

(0.75 + 1.885m )

We know

that tangential tooth load,

WT = (σo

× Cv) b. π m.y' = (σo × Cv) 3pN × π m ×

y'

= (σo × Cv) 3 × pc cos α × π m × y'

α)

= (σo ×

Cv) 3 π m cos α × π m × y'

... (Q b = 3 pN)

... (Q pN = pc cos

... (Q pc = π m)

Solving

this equation by hit and trial method, we find that

m = 5.5

say 6 mm Ans

Pitch diameter of the gear

We know

that the pitch diameter of the gear,

DG = m × TG = 6 × 24 = 144 mm Ans.

Face width

It is

given that the face width,

b = 3 pN = 3 pc cos α = 3 × π m

cos α

= 3 × π × 6

cos 30°

= 48.98 say

50 mm Ans.

End thrust on the gear

We know

that end thrust or axial load on the gear,

WA = Wr tan a

= 1790 N

Related Topics