Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Track Fittings and Fastenings

Some Fittings and Fastenings

Other Fittings and Fastenings

This section discusses malleable

cast iron inserts, rubber pads, composite liners, and pilfer-proof elastic

fastenings.

1 MCI Inserts

Malleable cast iron inserts are

directly fixed onto concrete sleepers during manufacture. MCI inserts are

manufactured according to the Indian Railway Standard (IRS) specification

T-32-76. These inserts are of two types.

(a) Stem-type

MCI insert for use in normal pre-tension concrete sleepers. This insert is

provided in concrete sleepers being manufactured in all the concrete sleeper

factories in India except the one located at Allahabad. The weight of the

stem-type insert is about 1.6 kg per piece.

(b) Gate-type

MCI insert for use in the post-tension concrete sleepers being manufactured at

Allahabad. The approximate weight of the gate-type MCI insert is 1.7 kg per

piece.

2 Rubber Pads

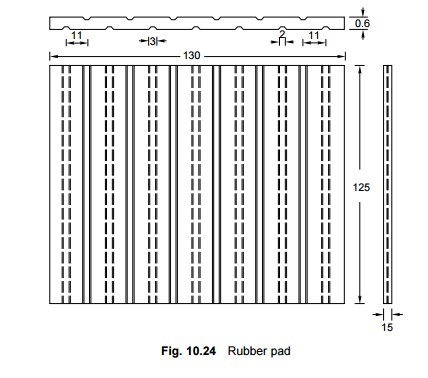

A rubber

pad (Fig. 10.24) is an integral part of an elastic fastening. It is provided

between the rails and the sleepers and has the following functions.

(a) It

absorbs shocks.

(b) It

dampens and absorbs vibrations.

(c) It

resists the lateral movements of the rails.

(d) It prevents

the abrasion of the bottom surface of the rail, which would otherwise come in

direct contact with the sleepers.

(e) It

provides electrical insulation between the rails in an electrified area. Indian

Railways uses grooved rubber pads of 4.5 mm thickness made of special

quality rubber. The grooves aid

in the uniform distribution of the load on sleepers and help to limit the

lateral expansion of the rubber under the pressure of dynamic loads.

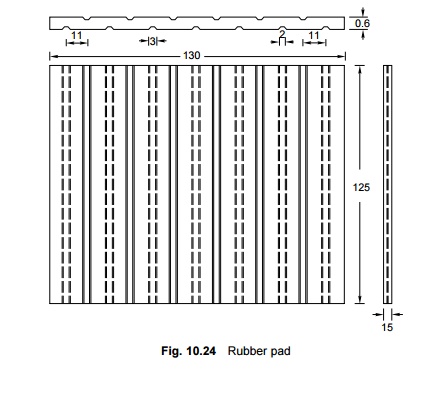

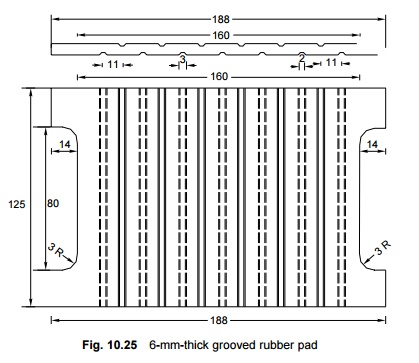

The RDSO

has recently designed 6-mm-thick grooved rubber pads with horns (Drg. No.

RDSO/T-37) for use on 60-kg rails (Fig. 10.25). It was noticed that normal

4.5-mm-thick rubber pads (IRST-37-1982) got crushed wihtin 6-7 years and,

therefore, thicker, grooved rubber pads with a service life of 15-20 years were

designed particularly for use on 60-kg UIC rails. These rubber pads are still

under trial.

3 Composite Liners

The Indian Railways mostly uses

nylon insulating liners. These liners, however, get crushed under the toe load

exerted by Pandrol clips. To eliminate such premature failure, the following

two types of composite liners have been evolved by RDSO.

Composite

liner with malleable cast iron and nylon components (Drg. No. RDSO/T653/1)

(b) Composite

liners with MS and nylon components (Drg. No. RDSO/T-1895) These liners have

been developed on the basis of the designs of the liners adopted

on British Railways, which have

been reported to provide trouble-free service. Composite liners have been used

on Indian Railways for the last few years and are serving the railways well.

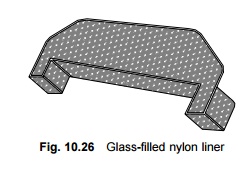

Glass-filled nylon liners

The RDSO

has developed glass-filled nylon liners (Fig. 10.26) (GFN-66) of 4 mm thickness

particularly for track-circuited areas and sections subject to server

corrosion. These glass-filled nylon liners are considered to be technically

superior to other liners because they are single piece, have a longer life, and

are free from corrosion. These liners are used extensively on Indian Railways

particularly with the ERC clip assembly on 60-kg and 52-kg rails and PRC

sleepers.

It has been noticed that the

GFN-66 liners tend to break, particularly in yards where these liners have been

fitted in the ERC clip assembly on concrete sleepers. This happens due to the

rusting of the rail surface and uneven seating. To avoid breakage of GFN-66

liners, it is necessary that proper precautions be taken during initial laying

to ensure that the rail surface is free from rust, etc. and that the liners are

fitted evenly on the 1 in 6 sloping surface of the rail flange.

A new design of GFN-66 liners

with a thickness of 6 mm (Drg. No. DSO/T-2505 Alt II) has recently been

developed and is expected to be sturdier and provide a better service life.

4 Pilfer-proof Elastic Fastenings for

Concrete Sleepers

The present design of elastic

fastenings (Pandrol clips) is such that they can be easily removed by a single

stroke of a hammer. A new type of elastic rail clip, which is pilfer-proof, has

been recently developed by RDSO. A pilfer-proof elastic fastening may be

defined as an elastic fastening system which is easy to fit in the assembly but

is difficult to remove without damaging the system.

The

design of a pilfer-proof elastic rail fastening consists of clip of almost the

same design as that of the normal elastic fastening as well as a new fitting

known as the pilfer-proof circlip. The circlip is a standard mechanical

component manufactured according to IS specifications and is generally used for

restraining the axial movements of the components mounted on shafts.

Related Topics