Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Track Fittings and Fastenings

Elastic Fastenings

Elastic Fastenings

The primary purpose of a

fastening is to fix the rail to the sleeper. The rail may be fixed either directly

or indirectly with the help of fastenings. In the process, the fastening gets

subjected to strong vertical, lateral, and longitudinal forces. The forces,

which are predominantly dynamic, increase rapidly with increasing loads and

speeds. In addition, vibrations are generated by moving loads mainly on account

of geometrical irregularities in the track and due to the forces set up by the

imbalance in the rolling stock. The traditional rigid fastening, which so far

has fulfilled its task to a certain extent, is no longer able to effectively

meet the present challenge of heavy dynamic forces and, therefore, becomes

loose under the impact of high-frequency vibrations of the order of 800 to 1000

cycles per second, even at a moderate speed of 100 kmph. In fact, this type of

fastening is unable to hold the rail to the sleeper firmly for a satisfactory

length of time because of the constant pressure exerted by moving loads. Due to

the shocks and vibrations caused by moving loads, the rigid fastenings become

loose, an interplay between the components of the track develops, track

parameters get affected, and rapid deterioration of the track begins. To solve

these problems a fastening which could safeguard track parameters and dampen

the vibrations is required. This has led to the development of the elastic

fastening.

1 Requirements of an Elastic Fastening

The ideal elastic fastening should meet the

following requirements.

(a) It should

hold the gauge firmly in place.

(b) It should

have an adequate toe load which should not reduce under service.

(c) It should

provide sufficient elasticity to absorb the vibrations and shocks caused by

moving loads.

(d) It should

help in keeping the track well maintained.

(e) It should

offer adequate resistance to lateral forces in order to maintain the stability

of the track.

(f) It should

provide adequate resistance to the longitudinal forces that are a result of the

acceleration of moving loads and other miscellaneous factors. These

longitudinal forces tend to cause the development of creep in the track.

(g) It should

be of the 'fit and forget' type so that it requires least maintenance.

(h) It should

not lose its properties even when it is used over and over.

(i) It should

have as few parts as possible and these parts should be easy to manufacture,

lay, and maintain.

(j) It should

be irremoveable so that once fitted it cannot be taken out and as such it

should not be vulnerable to sabotage or theft.

(k) It should

be universally applicable so that it can be used with wooden, steel, or

concrete sleepers.

(l) It should

be cheap and long lasting.

Types of Elastic Fastenings

An elastic fastening is usually in the form of a

clip. Various types of clips have been developed over the years; these are

discussed here in detail.

Pandrol

clip or elastic rail clip

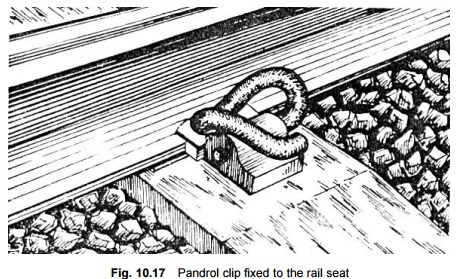

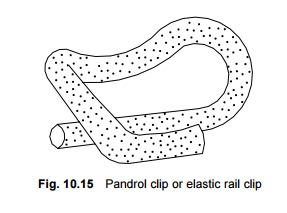

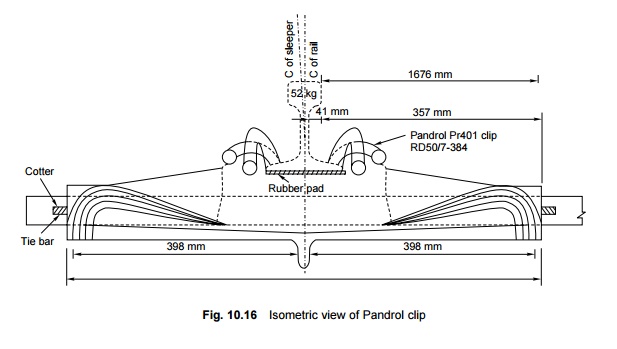

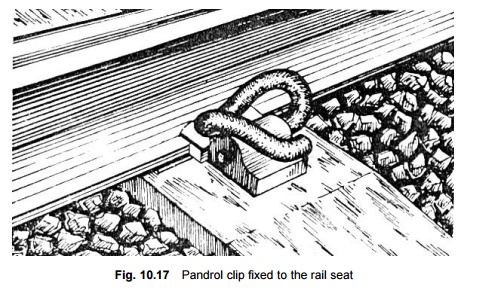

The

Pandrol PR 401 clip (also known as an elastic rail clip) (Fig. 10.15) is a

standard type of elastic fastening used on Indian Railways, earlier

manufactured by Messrs Guest, Keens & Williams. It is a 'fit and forget'

type of fastening that requires very little attention towards its maintenance.

The clip is made of a silico-manganese spring steel bar with a diameter of 20.6

mm and is heat treated. It exerts a toe load of 710 kg for a nominal deflection

of 11.4 mm. The toe load is quite adequate to ensure that no relative movement

is possible between the rail and the sleeper. Pandrol clips can be driven with

the help of an ordinary 4-pound hammer and require no special tools. In order

to ensure that the correct toe load is exerted, the Pandrol clip should be

driven to such an extent that the outer leg of the clip is flush with the outer

face of the CI insert. Figure 10.16 shows an isometric view of the clip fixed

on the rail while Fig. 10.17 shows the clip fixed to a rail seat.

The

Pandrol or elastic clip can be fixed on wooden, steel, cast iron, and concrete

sleepers with the help of a base plate and some other ancillary fittings.

Pandrol clips are the most widely used clips with concrete sleepers on Indian

Railways. Therefore, it becomes imperative that a detailed account of the same

be given.

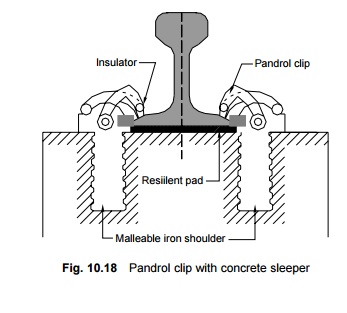

Concrete

sleepers with Pandrol/elastic clips In the case of concrete sleepers,

malleable cast iron inserts are punched directly into the sleepers during

manufacture. The Pandrol clip is fixed in the holes of the CI insert. A

4.5-mm-thick grooved rubber pad is provided under the rail seat to make it

doubly elastic. Insulated liners provide the necessary insulation (Fig. 10.18).

Drawbacks of Pandrol clip The

Pandrol clip suffers from the following drawbacks

1. Their use

makes the adjustment of the gauge impossible.

2. The

Pandrol clip has a point contact and this causes indentation on the foot of the

rail due to a heavy toe load and a small contact area.

3. It does

not provide enough safeguard from theft or sabotage because it can easily be

taken out using an ordinary hammer.

4. It gets

caught inside the malleable cast iron (MCI) insert during service.

Toe load measuring device This

device consists of a lever made of silico- manganese steel and is

designed to grip the Pandrol rail slip toe. It is used in conjunction with a

suitable block which is fitted on the rail head and acts as the fulcrum. To

operate the device, a force is gradually applied to the handle and the reading

of the dial gauge at which the Pandrol clip toe is just lifted above the rail

seat is noted. The reading of the dial gauge indicates the toe load, which is

pre-calibrated in the laboratory.

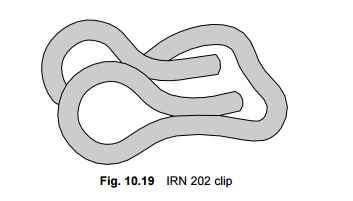

IRN 202 clip

The IRN

202 clip (Fig. 10.19) is an elastic fastening designed by RDSO to suit

two-block reinforced cement concrete (RCC) sleepers. The clip is manufactured

by the Republic Forge of Hyderabad using a silico-manganese spring steel bar of

diameter of 18 mm, suitably heat treated to Brinel hardness number (BHN) 375-

415. The assembly is designed for a toe load of 1000 kg and a toe deflection of

18.5 mm. The assembly has a creep resistance generally equal to 50% of the

total toe load of the rail.

The clip

essentially consists of outer legs connected by means of two coils. It is held

in position by a bolt and clamp arrangement. The clamp is made up of the same

material as the clip. The bolt, which has a diameter of 19 mm, is made of mild

steel. The clip holds the track gauge easily and effectively. The inner legs

rest against the bottom flange of the rail to provide an elastic gauge check.

After the clip is placed in position, the nut is tightened to depress the inner

legs with respect to the toe till these touch the sleeper surface. This stage

depends on the designed toe load and the toe load deflection. At this stage, it

is not possible to tighten the nut any further. The nut will remain in position

for quite some time, as the tension in the bolt does not vary much during

summer.

The

advantage of the IRN 202 clip is that the rail can be changed without removing

the fastening simply by loosening the bolt and pushing the rail out. However,

the IRN 202 clip suffers from the following drawbacks.

1. The

corrosion of the highly stressed part (heel) of the assembly can lead to the

development cracks.

2. It is not

a fit and forget type of fastening and requires frequent attention such as

oiling and tightening of the nuts to maintain the required toe load.

3. It is a

comparatively costlier and heavier clip.

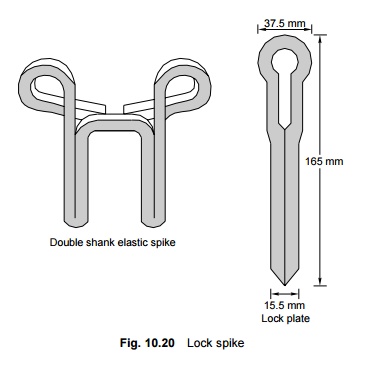

Lock spikes

Lock

spikes (Fig. 10.20) are manufactured by Messrs Lock Spike Ltd, London for use

with wooden sleepers. The lock spike type LG-20 has been tried on Indian

Railways. It is a 165-mm- (6.5-in.) long spike with a round section of diameter

16 mm (5/8"). The sizes of the holes bored into the sleeper are 14

mm and 12 mm for hard wood, and soft wood respectively. The spike, which

appears to have a good future, is still under trial.

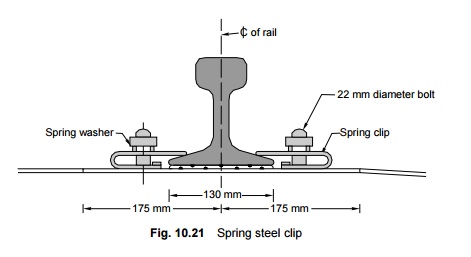

Spring steel clip

A large

number of spring steel clips (Fig. 10.21), supplied mostly by Messrs Guest,

Keens & Williams, have been tried on Indian Railways. The assembly consists

of a double elastic fastening used on a prestressed concrete sleeper. In this

assembly, the rail rests on a grooved rubber pad and is held vertically by a

pair of spring clips at each rail seat. The clip is pressed with the help of a

nut tightened on a 22-mm bolt, which is inserted from the underside of the

sleeper. The clip is manufactured using EN-48 steel. The nut is tightened to a

torque of 100 ft lb to obtain a resistance of 1 t per pair of clips. The clip

is still in its experimental stage on Indian Railways.

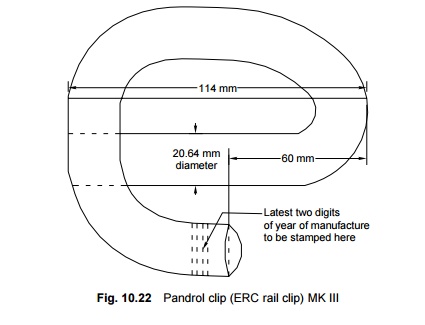

Elastic rail clip MK-III

The RDSO

has designed a new type of elastic rail clip known as ERC MK-III (Fig. 10.22)

which suits both 52-kg and 60-kg rails along with 6-mm-thick rubber pads. In

the case of 60-kg rails, two liners of 16 mm thickness are used, whereas in the

case of 52-kg rails, one liner of 16 mm thickness is used on the non-gauge side

and another liner of 10 mm thickness is used on the gauge side. The clip can

also be used with 6-mm-thick rubber pads in place of the usual 4.5-mm-thick

rubber pads on the existing 52-kg PRC sleeper.

The ERC

MK-III clip has been modified from the standard elastic rail clip to the extent

that the distance of the toe of the clip has increased with respect to the

centre leg. The space curves of the clip have also been modified to achieve a

higher toe load. The diameter of the standard ERC has been retained, i.e., 20.6

mm.

The new ERC MK-III has a toe load

of 900-1100 kg with a toe deflection of 15.5 mm. The clip is still under trial.

Limitations of elastic

rail clip The elastic clip (or Pandrol clip) presently being used

on Indian Railways has the following limitations.

1. The

elastic rail clip (ERC) does not permit 52-kg rails to be interchangd with

60-kg rails. Therefore, whenever traffic requirements demand the replacement of

52-kg rails with 60-kg rails, the sleepers also have to be replaced or costlier

special steel alloy rails have to be used.

2. The ERC

can be easily removed from the track.

3. The ERC

gets jammed/rusted in the insert and tends to lose the designed toe load.

The only

fastenings in the world proven to permit the interchangeability of 52-kg rails

with 60-kg rails are the HM fastenings of German design and the NABLA

fastenings of French design. The RDSO has recently designed an elastic rail

clip (mark III) which also permits interchangeability of the two types of

rails, but it is still in its trial stage.

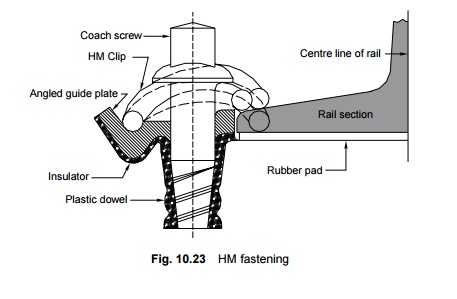

Herbert Meir fastening

The

Herbert Meir (HM) fastening (Fig. 10.23) basically consists of four coach

screws which are tightened against the plastic dowels of the PRC sleepers and

press the HM clip assembly to give the desired toe load. Each clip weighs about

510 g and can give a toe load of about 1 t. The gauge is maintained with the

help of an angled guide plate. A thin insulated shim is placed between the

angled plate and the concrete sleepers. A grooved rubber pad is placed below the

seat to provide the necessary dampening effect and resistance to the lateral

movement of rails.

The HM

fastening can be used for 52-kg as well as 60-kg rails by using a suitable size

of angled guide plates and insulating shims.

Related Topics