Chapter: Essential Anesthesia From Science to Practice : Clinical management : The anesthesia machine

Single-valve system with gas storage - The anesthesia machine

Single-valve system with gas

storage

In order

to save gas, we can provide for storage of the gas. Well known is the Mapleson

system, often used during

resuscitation and during transport of a

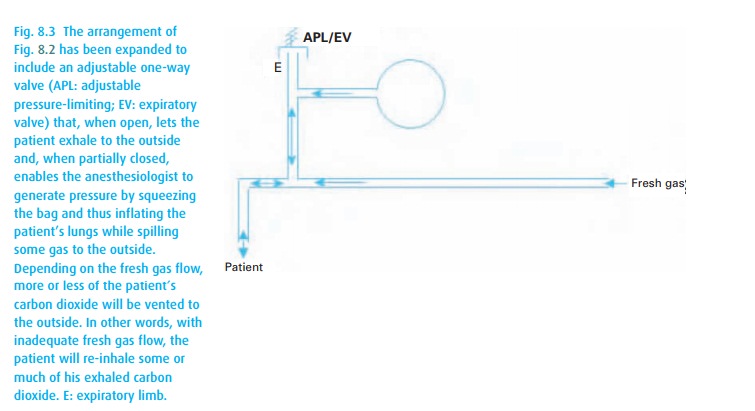

The system shown in Fig. 8.3is properly called a Mapleson D (as there are different arrangements

lettered A through F).

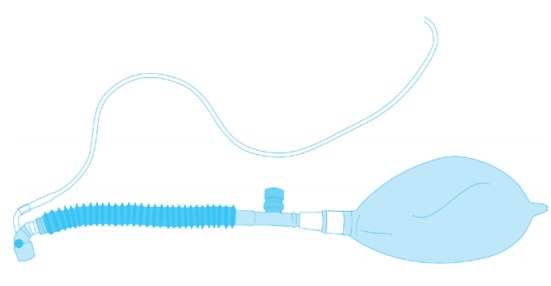

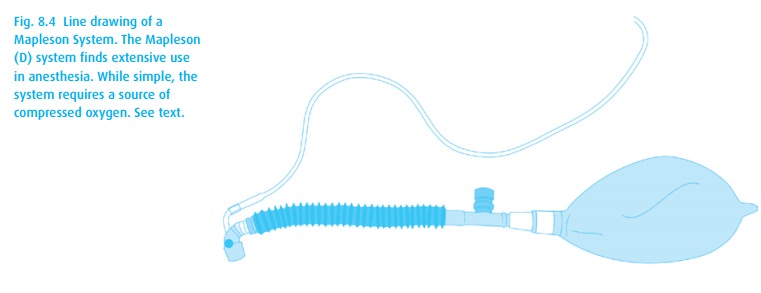

Figure 8.4shows the real thing. It is light and deceptively simple. To prevent rebreathing of exhaled carbon dioxide requires a relatively high fresh gas flow, both to meet inspiratory demand and to wash exhaled CO2 out of the tubing. Here, the excess gas escapes through an adjustable one-way (pop-off ) valve that prevents entrainment of room air. The pressure required to open the spring-loaded valve can be varied, enabling us to generate enough pressure (by squeezing the bag) to inflate the patient’s lungs. Slow respiratory rates help because, during a long pause between inspirations, the fresh gas will push the exhaled gas toward the pop-off valve. During spontaneous ventilation, the fresh gas flow should be as high as 200 to 300 mL/kg; for our patient, that would be 14–21 L/min. With manually controlled ventilation, 100 to 200 mL/kg will do. We will occasionally observe lower flow rates in clinical usage, causing unintended rebreathing of carbon dioxide. To be sure, err on the high side – which wastes a little gas and has no disadvantage to the patient – rather than on the low side, which causes rebreathing of carbon dioxide, the very problem patients in respiratory distress should be spared.

The

Mapleson systems require compressed gas.

Related Topics