Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Sensors, Actuators, and Other Control System Components

Sensors

SENSORS

A wide

variety of measuring devices is available for collecting data from the

manufactur ing process lor usc in feedback control. In general.a measuring

device is composed of two components: a sensor and a transducer. The sensor detects the physical variable of

interest (such astemperature. force. or pressure), The transducer converts the physical variable into an alternative form

(commonly electrical voltage),quantifying the variable in the con. version. The

quantified srgnat can be interpreted as the value of the measured variable. In

some cases, the sensor and transducer are the same device; for example, a limit

switch that converts the mechanical movement of a lever to close an electrical

contact.

To use

any measuring device. a calibration

procedure is required to establish the re lations.hip between the physical

variable to be measured and the converted output signal (such as voltage). The

ease with which the calibration procedure can be accomplished is one criterion

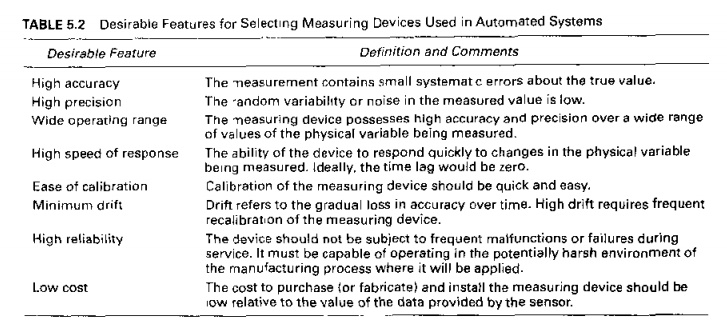

by which a measuring device can be evaluated. A list of desirable features of

measuring devices for process control is presented in Table 5.2. Few measuring

devices achieve perfect scores in all of these criteria. and the control system

engineer must decide which features are the most important in selecting among

the variety of available sensors and transducers for a given application

Consisreru

with our ctasstncartcn of process variables, measuring devices can be

classified into two basic categories: (1) analog and (2) discrete. An analog measuring device produces a

continuous analog signal such as electrical voltage. Examples are

thermocouples, strain gages.end potentiometers. The output signal from an

analog measuring device must be convened to digital data by an analogtodigital

converter (Section 5.3).A discrete

measuring device produces an output that can have only certain values, Discrete

sensor devices arc often divided into two categories: binary and digitaL A binary measuring device produces an

on/off signal.The most common devices operate by closing an electrical contact

from a normally open position. Limit switches operate in this manner. Other

binary sensors include photoelectric sensors and proximity switches. A digital measuring device produces a

digital output signal, either in the form of a set of parallel status bits [e.g

.•a photoelectric sensor array) or a series of pulses that can be counted

(e.g., an optical encoder). In either case, the digital signal represents the

quantity to be measured. Digital transducers are finding increased usc because

of the ease with which thev can be read when used as standalone measuring

instruments and because of their compatibility with digital computer systems.

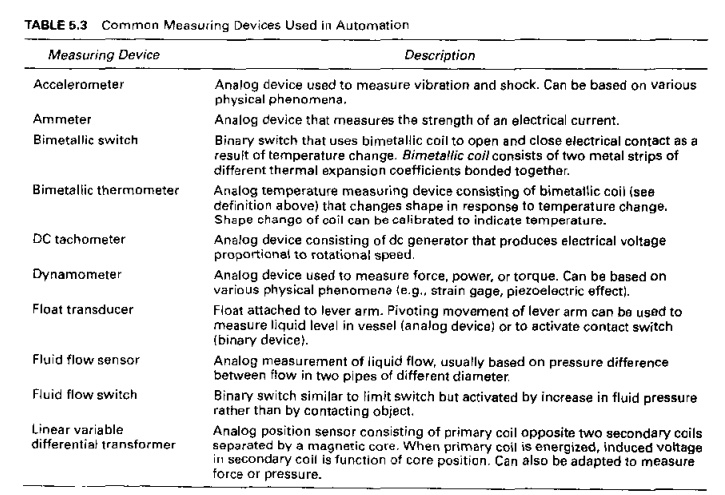

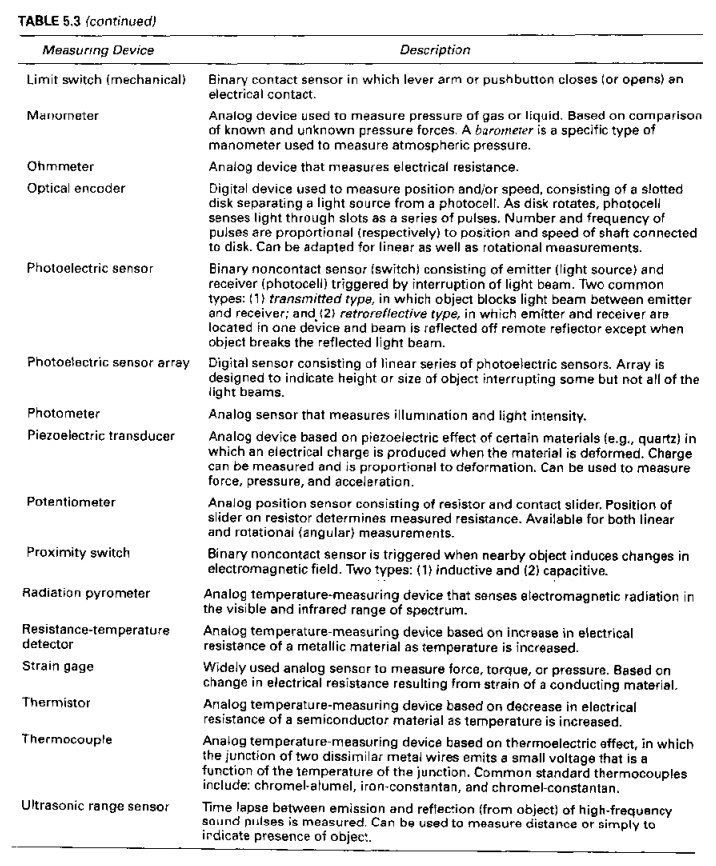

Several of the common sensors and measuring devices used in industrial control

systems are listed in Table 5.3

Related Topics