Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Sensors, Actuators, and Other Control System Components

Actuators

ACTUATORS

In

industrial control systems, an actuator

is a hardware device that converts a controller cornmand signal into a change

in a physical parameter. The change in the physical parameter is usually

mechanical. such as position or velocity change. An actuator is a

transducer.because it changes one type of physical quantity. say electric

current, into another type of physical quantity, say rotational speed of an

electric motor. The controller command signal is usually low level, and so an

actuator may also include an amplifier

to strengthen the ~ignal sufficiently 10 drive the actuator

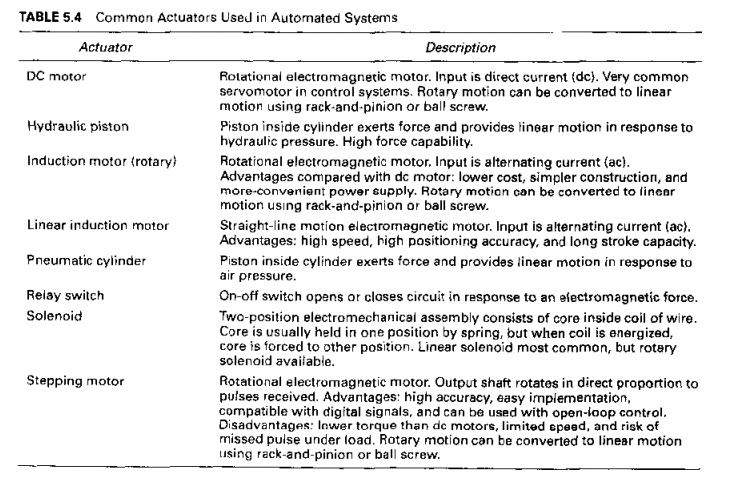

A list of

common actuators is presented in Table 5,4. Depending on the type of amplifier

used. most actuators can he classified into one of three categories: (1)

electrical,

(2)

hydraulic, and (3) pneumatic. Electrical

aCluators are most common; they include Ole and de motors of various kinds,

stepper motors. and solenoids. Electrical actuators include both linear devices

(output is linear displacement) and rotational devices (output is rotational

displacement or velocity). Hydraulic

actuators use hydraulic fluid to amplify the controller command signal. Thc

available devices provide both linear and rotational motion.

Hydraulic

actuators are often specified when large forces are required. Pneumatic octuators usc compressed air

(typically "shop air" in the factory environment) as the driving power. Again. both linear and

rotational pneumatic actuators are available. Because of the relatively

10••••airpressures. involved, these actuators are usually limited to relatively

low force applications compared with hydraulic actuators.

Related Topics