Chapter: Aquaculture Engineering : Transport of Live Fish

Sea transport of Live Fish

Sea transport

Large quantities of fish can be effectively trans-ported by sea. This may be carried out by special boats, well boats or by hauling the sea cages or other floating installations with boats. Compared to trucks on shore, the advantage with using well boats is that the well is much larger than the truck tanks so the amount of transported fish can be increased and therefore the costs per fish transported reduced. Larger tanks are also better for larger fish, for instance for transporting fish to the slaughter-house because the available volume for the fish to swim in is greater.

The fish can also be transported by hauling the net cage or another closed construction. However, the recommended drag velocity is quite low; this is of course also species dependent, but is never recommended to be above 1 or 2 knots. Such veloci-ties will also impose large forces on the dragged constructions.

Well boats

Boats used for live fish transport are equipped with wells (internal tanks) for holding the fish (Fig. 18.3). Well boats have for many decades been used for transporting various species, such as herring and pollack, from traditional fisheries. The same boats may today be used for transporting farmed fish. Special systems for loading and unloading the fish may be installed. The normal size of well boats varies from 20 to 60 m and they may accommodate up to 150 t of live fish. Traditional V-shaped hulls are usually used, but catamaran types that are faster

The well

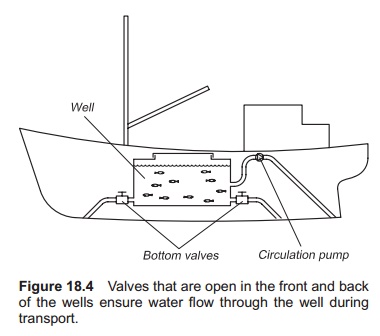

In the well boat there is a constant flow of new water through the well to ensure enough oxygen is supplied to the fish and the waste products are removed. Special well valves are placed in the front and in the back of the well (Fig. 18.4). If the boat is moving these valves are opened and new water will flow through the well from front to back. The well valves are operated directly from the bridge. If the well boat is in dock, large circulation pumps ensure the renewal of water in the well and by this the supply of necessary oxygen to the fish and removal of waste products.

When the well boat is transporting fish it may be necessary to close the well valves in some areas (special zones) and continue with closed valves. Reasons for this are to avoid possible transfer of disease either from surroundings to the fish in the well, or from the fish in the well to the surround-ings. Special zones can be areas near fish farms or important natural fish stocks. On these occasions it is necessary to ensure that the fish get enough oxygen even if the circulation pumps are inopera-tive. An oxygen supply system or air blower is therefore necessary, together with the necessary distribution system, for example diffusers located in the bottom of the well. Most modern well boats are

equipped with systems for adding oxygen and may carry the fish for a long period of time without opening the well valves. The wells function similarly to those used on truck transport. Similarly the tanks can be equipped with systems for individual circulation of the water and also water purification (re-use) systems. The well boat may also be equipped with a refrigerated seawater (RSW) system for cooling the seawater, to keep a low temperature in the well and also to chill the live fish before slaughter.

Well boat size commonly varies from 50 to 1000 m3. Inside the well is normally divided into several tanks separated by fixed walls. The construction and surface of the sidewalls and bottom must be designed not to damage the fish. Use of nets for dividing the well into additional compartments is therefore not satisfactory. It is also important that the well is designed in a way that ensures good water distribution and exchange of the total water volume. Well boats with circular tanks have also been constructed. The well will then function in the same way as a circular tank with the same flow pattern, and a very good distribution of the incoming water is ensured.

As for tanks on trucks, it is important that the wells are easy to clean and disinfect. It is also important to have control of the real well volume when adding disinfectant.

Density

As for truck transport, the transport density will vary with the species, but here it is also important from an economic perspective. For Atlantic salmon, the density is normally around 35–50 kg/m3, and for adult fish to slaughterhouse densities of between 150 and 180 kg/m3 have been reported. When transporting large amounts of fish to the processing plant, the cargoes are very valuable. A well capacity of 1000 m3 and a fish density of 150 kg/m3 mean that 150 t of fish is being transported. If the price is 3 €/kg the total value of the cargo is 450 000 €. This also shows the necessity of control to avoid accidents.

Instrumentation

Instrumentation to control water temperature, oxygen content and salinity, when transporting in seawater, is essential in well boats. In all boat trans-port it is important to have proper records and to keep a logbook. This can either be done manually or in a computer log with automatic data-logging of the parameters.

When transporting fish by well boat, special attention must be given to variations in temperature and salinity in the sea because these changes may be very stressful for the fish. Large variations in temperature may occur when there are large sup-plies of freshwater, for example close to the outlet of large rivers. Variation in water quality during transport is not good; for instance, there may be reduced salinity just outside large rivers and also large organic burdens so that a mixing zone with negative water quality may occur.

Boat transport in rough weather must also be avoided. The fish in the well boat may suffer from some kind of seasickness. Some species will attempt to compensate for the wave pressure and try to stay at the same depth in the well by taking air in and out of the swim bladder. This may exhaust the fish totally and they will sink to the bottom of the well where they will lie, sliding about on the bottom of the well so incurring wounds and losing scales. Therefore it is important to listen to the weather forecast before transport, and record the weather conditions and approximate wave height.

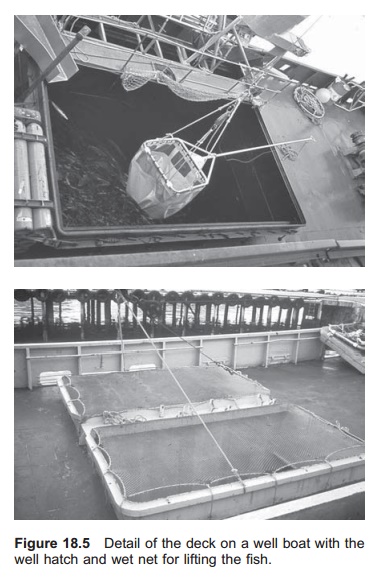

All well boats have some type of equipment for loading and unloading the fish. Some sort of fish pump, for instance an ejector or vacuum–pressure pump, is normally used today, but a wet net may also be employed (Fig. 18.5). There have also been some specially designed boats that allow the fish to move in and out of the well voluntarily. This is pos-sible by lifting the stern so that the well is opened. Sliding walls can be used to crowd the fish without pumping the water out from the well and reducing the water level. It is thus possible to reduce the volume in the well by moving one wall.

Many well boats are also equipped with grading equipment so that they can be used to grade fish in sea cages in addition to transporting fish.

Related Topics