Chapter: Fiber optics and Laser instruments : Optical Fiber and Their Properties

Scattering losses

Scattering losses

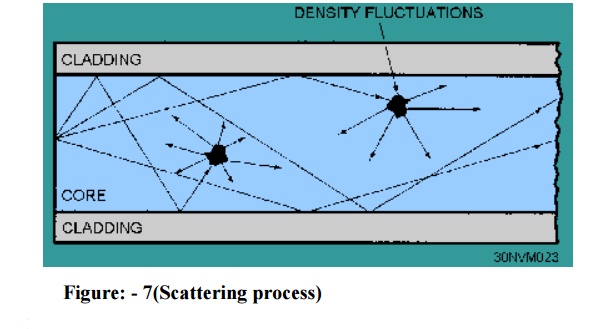

Basically, scattering losses are caused by the

interaction of light with density fluctuations within a fiber. Density changes

are produced when optical fibers are manufactured. During manufacturing,

regions of higher and lower molecular density areas, relative to the average

density of the fiber, are created. Light traveling through the fiber interacts

with the density areas as shown in Light is then partially scattered in all

direction.

In commercial fibers operating between 700-nm and

1600-nm wavelength, the main source of loss is called Rayleigh scattering. As the wavelength increases, the loss caused

by Rayleigh scattering decreases. If the size of the defect is greater than

one-tenth of the wavelength of light, the scattering mechanism is called Mie scattering.

1. Linear scattering losses

1. Rayleigh scattering

It occurs because the molecules of silicon dioxide have some freedom when adjacent to one another. Thus, setup at irregular positions and distances with respect to one another when the glass is rapidly cooled during the final stage of the fabrication process. Those structural variations are seen by light as variations in the refractive index, thus causing the light to reflect – that is, to scatter – in different directions

Rayleigh scattering is a scattering of light by particles much smaller than the wavelength of the light, which may be individual atoms or molecules. Rayleigh scattering is a process in which light is scattered by a small spherical volume of variant refractive index, such as a particle, bubble, droplet, or even a density fluctuation.

As light

travels in the core, it interacts with the silica molecules in the core.

Rayleigh scattering is the result of these elastic collisions between the light

wave and the silica molecules in the fiber. Rayleigh scattering accounts for

about 96 percent of attenuation in optical fiber

Causes of

Rayleigh Scattering:

It

results from non-ideal physical properties of the manufactured fiber.

It

results from inhomogeneities in the core and cladding.

Because

of these inhomogeneities problems occur like –

a) Fluctuation

in refractive index

b) density

and compositional variations.

Minimizing of Rayleigh Scattering:

Rayleigh

scattering is caused due to compositional variations which can be reduced by

improved fabrication.

Equation of Rayleigh Scattering:

Light

scattering can be divided into three domains based on a dimensionless size

parameter, α which is defined as

A = πDp / λ

where πDp is the circumference(The

boundary line of a circle) of a particle and λ is the wavelength of incident

radiation. Based on the value of α, these domains are:

α<<1:

Rayleigh scattering (small particle compared to wavelength of light) α≈1: Mie

scattering (particle about the same size as wavelength of light)

2. Mie scattering

Non

perfect cylindrical structure of the fiber and imperfections like

irregularities in the core-cladding interface, diameter fluctuations, strains

and bubbles may create linear scattering which is termed as Mie scattering

Mie scattering is a

scattering of light by particles approximately equal to the wavelength of the light, which may be individual atoms or

molecules.

Causes of Mie Scattering:

Occurred

due to inhomogeneities in the composition of silica. (i.e. inhomogeneities in

the density of SiO2 )

Irregularities

in the core-cladding interface, Difference in core cladding refractive index,

Diameter fluctuations

Due to

presence of strains and bubbles.

The

scattering caused by such inhomogeneities is mainly in the forward direction

depending upon the fiber material, design and manufacture.

Minimizing of Mie scattering

Mie

scattering is mainly caused by inhomogeneities which can be minimized by

Removing

imperfection due to glass manufacturing process

Carefully

controlled extrusion(To push or thrust out) and coating of the fiber

Both Mie

and Rayleigh scattering are considered elastic scattering (elastic scattering

is also called Linear scattering) processes, in which the energy (and thus

wavelength and frequency) of the light is not substantially changed.

2. Nonlinear scattering losses

Specially

at high optical power levels scattering causes disproportionate attenuation,

due to non linearbehavior. Because of this non linear scattering the optical

power from one mode is transferred in either the forward or backward direction

to the same, or other modes, at different frequencies. The two dominant types

of non linear scattering are :

a) Stimulated

Brillouin Scattering and

b) Stimulated

Raman Scattering.

a) Stimulated Brillouin Scattering:

This is

defined as the modulation of light through thermal molecular vibration within

the fiber. The scattered light contains upper and lower side bands along with

incident light frequency. An incident photon produces a scattered photon as

well as a photon of acoustic frequency. The frequency shift is maximum in the

backward direction and it is reduced to zero in the forward direction. The

threshold optical power for Brillion scattering is proportional to

d2λ2αB

b) Stimulated Raman Scattering:

Here, the

scattered light consists of a scattered photon and a high frequency optical

photon. Further, this occurs both in the forward and backward direction in the

optical fiber. The threshold optical power for Raman scattering is about three

orders of magnitude higher than the Brillouin threshold for the given fiber,

The threshold optical power for Raman scattering is proportional to

d2λ2αR

Related Topics