Chapter: Mechanical : Gas Dynamics and Jet Propulsion : Flow Through Ducts

Rayleigh line (or) curve

Rayleigh line (or) curve

The friction less flow of a perfect gas through a constant

area duct in which heat transfer to or from the gas is the dominant factor

bringing about changes in the flow is referred to as Rayleigh flow or diabetic

flow. In thermodynamic coordinates, the Rayleigh flow process can be described

by a curve known as Rayleigh line and is defined as the locus of quasi- static

thermodynamic state points traced during the flow. The Rayleigh line satisfies

the equation of state along with simple forms of continuity and momentum

equation.

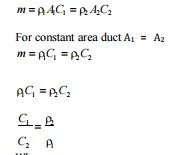

Governing Equations

In order to formulate the equation for the Rayleigh line,

let us consider steady flow of a perfect gas through a constant area passage in

which transfer of heat with the surroundings is the major factor responsible

for changes in fluid properties. The simple form of continuity equation for

steady one dimensional flow in a constant area duct is

Where

G- Mass flow density.

c- Velocity of sound.

p- Density of fluid.

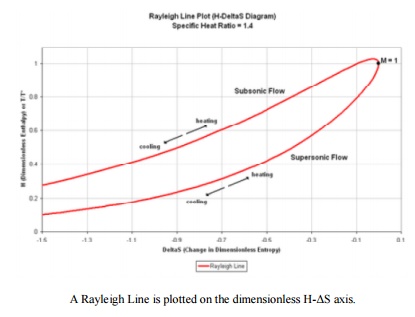

Equation 1 may be used for representing Rayleigh line on

the h- s diagram, as illustrated in fig shown in below. In general, most of the

fluids in practical use have Rayleigh curves of the general form shown in fig.

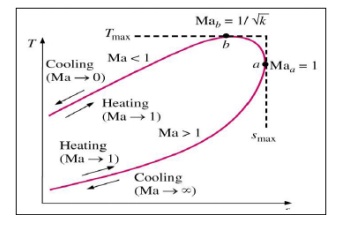

The portion of the Rayleigh curve above the point of

maximum entropy usually represents subsonic flow (M<1) and the portion below

the maximum entropy point represents supersonic flow (M>1).

An entropy increases due to heat addition and entropy

decreases due to heat rejection. Therefore, the Mach number is increased by

heating and decreased by cooling at subsonic speeds. On the other hand, the

Mach number is decreased by heating and increased by cooling at supersonic

speeds. Therefore, like friction, heat addition also tends to make the Mach

number in the duct approach unity. Cooling causes the Mach number to change in

the direction away from unity.

Rayleigh Flow

Rayleigh

flow refers to adiabetic flow through a constant area duct where the effect of

heat addition or rejection is considered. Compressibility effects often come into

consideration, although the Rayleigh flow model certainly also applies to

incompressible flow. For this model, the duct area remains constant and no mass

is added within the duct. Therefore, unlike Fanno flow, the stagnation

temperature is a variable. The heat addition causes a decrease in stagnation

pressure which is known as the Rayleigh effect and is critical in the design of

combustion systems. Heat addition will cause both supersonic and subsonic Mach

numbers to approach Mach 1, resulting in choked flow. Conversely, heat

rejection decreases a subsonic Mach number and increases a supersonic Mach

number along the duct. It can be shown that for calorically perfect flows the

maximum entropy occurs at M = 1. Rayleigh flow is named after John Strutt, 3rd

Baron Rayleigh.

Theory

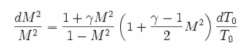

The Rayleigh flow model begins with a differential

equation that relates the change in Mach number with the change in stagnation

temperature, T0. The differential

equation is shown below.

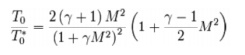

Solving the differential equation leads to the relation

shown below, where T0* is the stagnation temperature at the throat location of the

duct which is required for thermally choking the flow.

Fundamental Equations

The

following fundamental equations will be used to determine the variation of flow

parameters in Rayleigh flows.

Continuity equation

We know that

Mass flow rate,

Where ;-

C1

–Velocity of fluid at inlet-m/s

C2

–Velocity of fluid at outlet-m/s

- Density of fluid at

inlet-kg/m3

- Density

of fluid at out let-kg/m3

Momentum equation

Momentum equation between

state 1nad 2 is given by p1 A mc1 p2

A mc2

P1 A P2 A mc2 mc1

P1 P2 A m

c2 c1

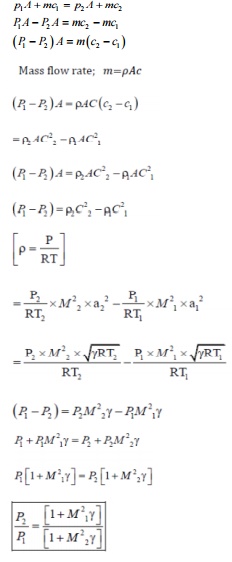

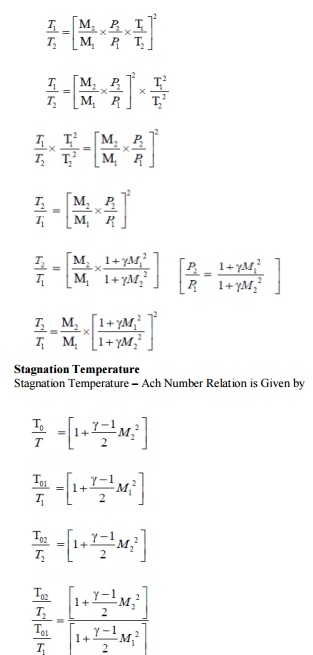

Ø Mach Number

The Mach number at the two states are

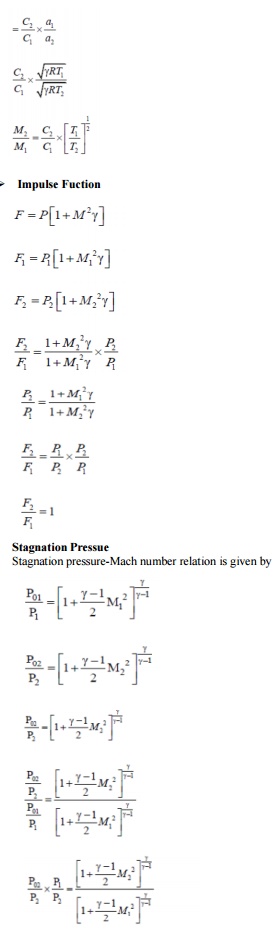

Stagnation Pressue

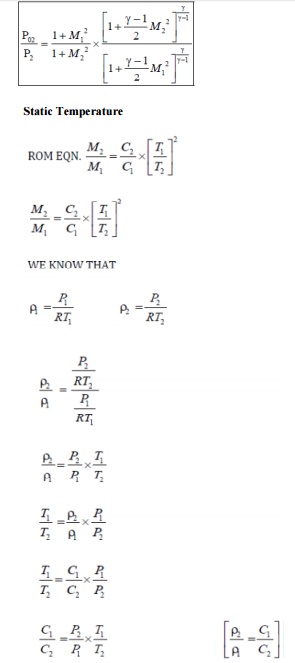

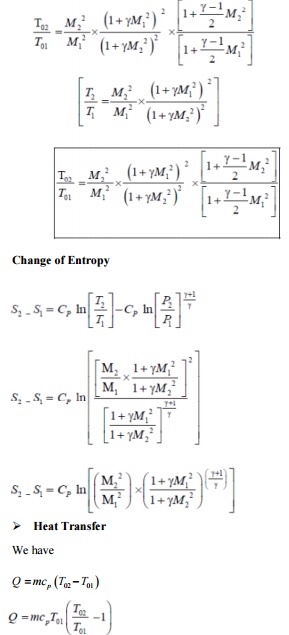

Stagnation Temperature

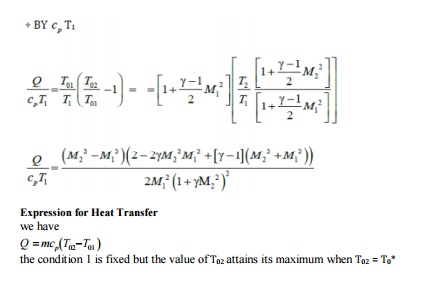

Expression

for Heat Transfer we have

Q mcp T02 T01

the condition 1 is fixed but

the value of T02

attains its maximum when T02 = T0*

Problems based on Rayleigh

flow

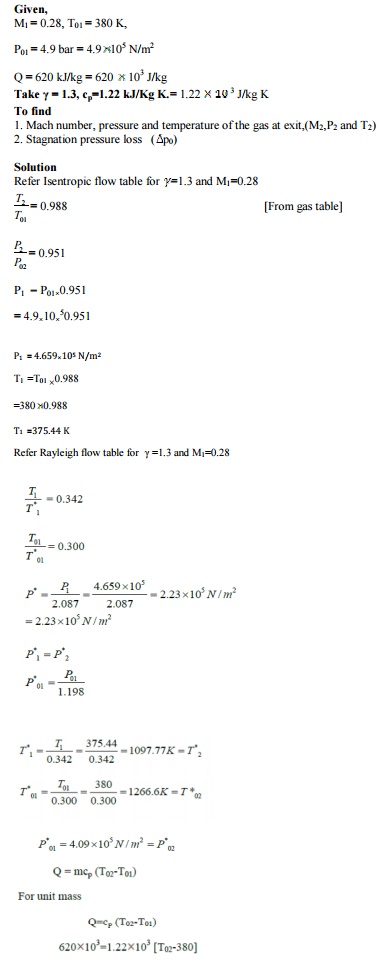

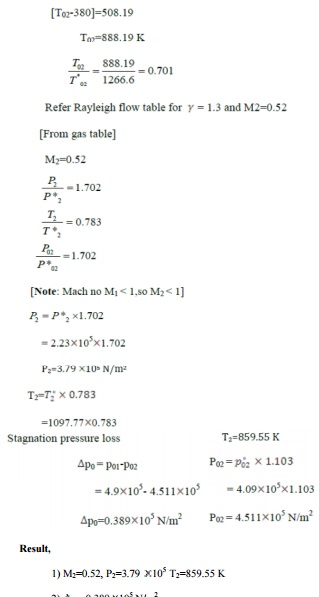

1.The

condition of gas in a combustion chamber at entry are M1=0.28, T01=380 K,

P01=4.9 bar. The heat supplied in the combustion chamber is 620 kJ/kg.Determine

Mach number, pressure and temperature of the gas at exit and also determine the

stagnation pressure loss during heating. Take γ= 1.3, cp=1.22 kJ/Kg K.

Given,

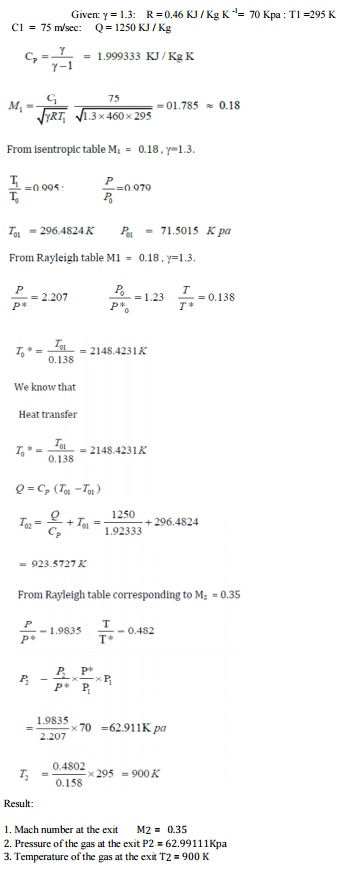

2.A

gas (γ=1.3 and R = 0.46 KJ / Kg K) at a pressure of 70 Kpa and temperature of

295 K enters a combustion chamber at a velocity of 75 m / sec. The heat supplied

in a combustion chamber is 1250 KJ / Kg .Determine the Mach number, pressure

and temperature of gas at exit.

Given:γ=1.3: R = 0.46 KJ / Kg K -1= 70 Kpa :

T1 =295 K C1 = 75 m/sec: Q = 1250 KJ / Kg

Related Topics