Chapter: Mechanical : Gas Dynamics and Jet Propulsion : Flow Through Ducts

Rayleigh Flow (Duct Flow with Heat Transfer and Negligible Friction)

Rayleigh Flow (Duct Flow

with Heat Transfer and Negligible Friction)

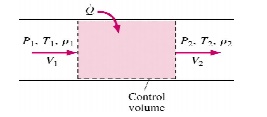

Flow in a constant area duct with heat

transfer and without friction is known as Rayleigh flow . Many compressible

flow problems encountered in practice involve chemical reactions such as

combustion, nuclear reactions, evaporation, and condensation as well as heat

gain or heat loss through the duct wall Such problems are difficult to analyze

Essential features of such complex flows can be captured by a simple analysis

method where generation/absorption is modeled as heat transfer through the wall

at the same rate

In

certain engineering processes, heat is added either by external sources across

the system boundary by heat exchangers or internally by chemical reactions in a

combustion chamber. Such process are not truely adiabatic, they are called

adiabatic processes.

Ø Applications

The

combustion chambers inside turbojet engines usually have a constant area and

the fuel mass addition is negligible. These properties make the Rayleigh flow

model applicable for heat addition to the flow through combustion, assuming the

heat addition does not result in dissociation of the air-fuel mixture.

Producing a shock wave inside the combustion chamber of an engine due to

thermal choking is very undesirable due to the decrease in mass flow rate and

thrust. Therefore, the Rayleigh flow model is critical for an initial design of

the duct geometry and combustion temperature for an engine.

The Rayleigh flow model is also used

extensively with the Fanno flow model. These two models intersect at points on

the enthalpy-entropy and Mach number-entropy diagrams, which is meaningful for

many applications. However, the entropy values for each model are not equal at

the sonic state. The change in entropy is 0 at M = 1 for each model, but the

previous statement means the change in entropy from the same

arbitrary point to the sonic

point is different for the Fanno and Rayleigh flow models.

Ø Combustion

processes.

Ø Regenerator,

Ø Heat

exchangers.

Ø Inter

coolers.

The

following are the assumptions that are made for analyzing the such flow

problem.

Ø One

dimensional steady flow.

Ø Flow

takes place in constant area duct.

Ø The

frictional effects are negligible compared to heat transfer effects..

Ø The

gas is perfect.

Ø Body

forces are negligible.

Ø There

is no external shaft work.

Ø There

is no obstruction in the flow.

Ø There

is no mass addition or rejection during the flow.

Ø The

composition of the gas doesn’t change appreciably during the flow.

Related Topics