Chapter: Mechanical : Quality Management : Introduction

Quality Management

Quality Management

1 Introduction

1.1 Prerequisite Discussions of Quality

2 Concept

2.1. Need for Quality

2.2. Evolution of quality

2.3. Defining quality

3 Dimensions of quality

3.1 Dimensions of service quality

3.2 Definition of TQM

4 Characteristics Of TQM

4.1 Basic Concepts of TQM

5 TQM Frame work or (ELEMENTS OF TQM)

6 Principles of tqm

7 Obstacles (barriers) in implementing tqm

8 Benefits of tqm

9 Contributions of Deming

10 The juran trilogy

11 Contributions of Crosby

11.1 Crosby’s fourteen points

INTRODUCTION

PREREQUISITE DISCUSSIONS

Quality is in its essence a way of management of the

organization.

Quality is conformance to

customer requirements. The requirements have many dimensions. The number of

quality experts also called quality gurus contributed to the evolution of

quality.

AN

INTRODUCTION:

A name itself is sufficient to describe everything but a bit

more clarification will add to a base for the description.

Total quality management is a management’s approach towards the quality, it can

be in regard

to products, customer satisfaction and

employees satisfaction. The concept of TQM

was developed by an American W. Edwards Deming and i.e.

why it is called as Deming’s concept of TQM .He introduced this concept

for improving the quality of various products and services. Earlier it was just

related with the quality of products which a organization is producing but now

other concepts like marketing, finance design, customer service has also joined

the area. Which means that now good numbers of things are there to manage. TQM

works on one belief that mistakes can be avoided and defects can be prevented.

And management should believe in watching each and every step.

TQM is now a day’s called

as TPM (total productivity management) and an organization needs to

consider ABCD for the effective application of TQM where A stands for accident

cure , B stands for breakdown , C stands for cost reduction and D stands for

damage. This policy of ABCD is in relation to product and if TQM needs to be

introduced a positive attitude from the side of management and employees is

required and then a collective effort will come up. TQM should give chance

for unleashing employee’s creativity and potential. The aim of TQM is to reduce

variations in quality of the products as well as in the working of whole

organization. For the successful implementation of TQM, an organization must

consider the commitment from all the level of organization. A concept of Six

sigma is a part of TQM. It is a strategy developed by Motorola and it

helps to detect the defects and to remove them.

TQM talks about the satisfaction of customer, supplier,

employees etc. and it requires continuous improvement. If the workers of an

organization are efficiently working then their morale will go up. TQM works

effectively if the organization works in a family manner. Here management is

like a father, employees are the children and manager is like mother and as father

and mother takes care for their home collectively the same way , management and

managers are supposed to take care for their organization with the help of tool

called TQM. Total quality management is called total because entire

organization is involved, Quality means degree of excellence. And management in

literal sense means getting things done by others. In a TQM effort, all members

of an organization participate in improving processes, products, services and

the culture in which they work. The earlier introduced quality management

concept is now taken over by Total quality management. To have effective TQM

the first requirement is strong internal motivation and emotional involvement

for implementation. So the concept of TQM talks about adopting the new policy,

creating quality products, eliminate defects, estimate for breakdown, accidents

etc . Hence TQM should be purpose driven so first the whole organization should

be willing to accept the change then only TQM can actually affect the

organization in a positive way.

CONCEPT

Need for quality:

The need for quality was felt,

during World War II due to the unprecedented need for manufacture goods. From

them on methodologies for assuring quality in products and services evolved

continuously finally lead to TQM.

Evolution

of quality (or) GURUS OF TQM:

SHEWHART - Control chart theory

- PDCA Cycle

DEMING - Statistical Process Control

JURAN - Concepts of SHEWHART

- Return on Investment (ROI)

FEIGANBAUM - Total Quality Control

- Management involvement

- Employee involvement

- Company wide quality control

ISHIKAWA - Cause and Effect Diagram

- Quality Circle concept

CROSBY - “Quality is Free”

- - Conformance to requirements

TAGUCHI - Loss Function concept

- Design

of Experiments

DEFINING

QUALITY:

Quality

is fitness for use

Quality

is conformance to requirements

Quality

is the totality of features and characteristics of a product or service that

bear on its ability to

satisfy

stated and implied needs of customer.

Quality

can be quantified as follows

Q = P / E

where,

Q = Quality

P = Performance

E = Expectation

DIMENSIONS

OF QUALITY:

-------------------------------------------------------------------------------------------------

Dimension Meaning

and Example

-------------------------------------------------------------------------------------------------

Performance Primary product characteristics,

such as the brightness of the picture

Features Secondary characteristics, added

features, such as remote control

Conformance Meeting specifications or industry standards, workmanship

Reliability Consistency

of performance over time, average time of the unit to fail

Durability Useful

life, includes repair

Service

Resolution

of problems and complaints, ease of repair

Response Human –

to – human interface, such as the courtesy of the dealer

Aesthetics Sensory

characteristics, such as exterior finish

Reputation Past

performance and other intangibles, such as being ranked first

1.3.1 Dimensions of service quality

Reliability Refers to the dependability of the service providers and their

ability to keep

their promises.

Responsiveness Refers to the reaction time of the service.

Assurance Refers

the level of certainty a customer has regarding the quality of the service

provided.

Empathy Being

able to understand the needs of the customer as an individual.

Tangibles Similar

to the physical characteristics of quality of products.

Other Dimensions Time, Courtesy, Timeliness, consistency, accuracy,

credibility and security.

Total

Quality Management (TQM) is an enhancement to the traditional way of doing

business.

Definition

of TQM

Art of

managing the whole to achieve excellence.

Total - Made

up of the whole

Quality - Degree

of Excellence a Product or Service provides.

Management - Art

of handling, controlling, directing etc.

TQM is the application of quantitative methods and human

resources to improve all the processes within an organization and exceed CUSTOMER

NEEDS now and in the future.

CHARACTERISTICS

OF TQM

The above

definitions revealed the following characteristics of TQM :

1. TQM is a

customer oriented.

2. TQM

required a long term commitment for continuous improvement of all processes.

3. TQM is

teamwork.

4. TQM

requires the leadership of top management and continuous involvement.

5. TQM is a

strategy for continuous improving performance at all levels and in all areas of

responsibility.

Basic

Concepts of TQM:

1.

A committed and involved management.

2.

An unwavering focus on the customer both

internally and externally.

3.

Effective involvement and utilization of entire

work force,

4.

Continuous improvement of the business and

production process.

5.

Treating suppliers as partners.

6.

Establish performance measures for the processes.

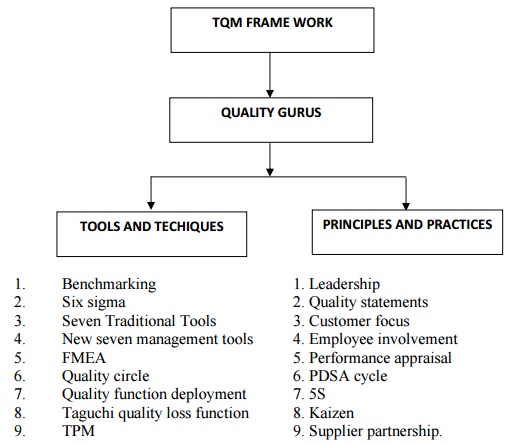

ELEMENTS

OF TQM

A

framework summarizing the important elements of TQM discussed in this text.

Three

elements of TQM include

1. The

philosophical elements of TQM stress the operation of the company

using quality as the integrating element.

2. The

generic tools consist of various statistical process control

(SPC) methods that are used for problem solving and continuous

improvement by quality teams. Quality function deployment is typically used by

managers to drive the voice of the customer into the organization.

3.

Tools of the QC department consists

of statistical quality control (SQC) methods such as sampling

plans,

process capability and Taguchi methods.

TQM Frame work:

TOOLS AND T

1. Benchmarking

2. Six sigma

3. Seven Traditional Tools

4. New seven management tools

5. FMEA

6. Quality circle

7. Quality function deployment

8. Taguchi quality loss function

9. TPM

PRINCIPLESPRACT

1. Leadership

2. Quality statements

3. Customer focus

4. Employee involvement

5. Performance appraisal

6. PDSA cycle

7. 5S

8. Kaizen

9. Supplier partnership.

Approach:

Continuous

improvement process.

Measures:

Performance

Measures

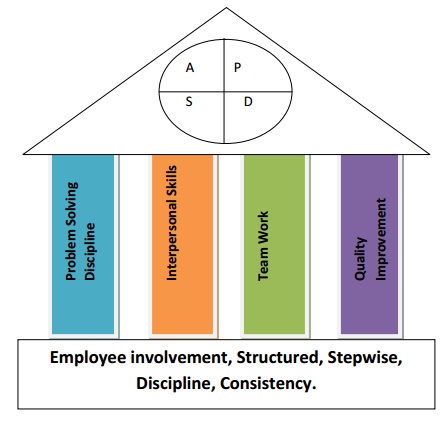

PRINCIPLES

OF TQM

Ø Customer’s

requirements must be met the first time, every time.

Ø There

must be agreed requirements, for both internal and external customers.

Ø Everybody

must be involved, from all levels and across all functions.

Ø Regular

communication with staff at levels is must. Two way communication at all levels

must be promoted.

Identifying

training needs and relating them with individual capabilities and requirements

is must.

Ø Top

management’s participation and commitment is must.

Ø A culture

of continuous improvement must be established.

Ø Emphasis should

be placed on purchasing and supplier management

Ø Every job

must add value.

Ø Quality

improvement must eliminate wastes and reduce total cost.

Ø There

must be a focus on the prevention of problems.

Ø A culture

of promoting creativity must be established.

Ø Performance

measure is a must at organization, department and individual levels. It helps

to asses and meet objectives of quality.

Ø There

should be focus on team work.

OBSTACLES

(BARRIERS) IN IMPLEMENTING TQM :

Ø Lack of

Management Commitment

Ø Inability

to change Organizational culture

Ø Improper

planning

Ø Lack of

continuous training and education

Ø Incompatible

organizational structure and isolated individuals and departments

Ø Ineffective

measurement techniques and lack of access to data and results

Ø Paying

inadequate attention to internal and external customers

Ø Inadequate

use of empowerment and teamwork

Ø Failure

to continually improve

BENEFITS

OF TQM:

Ø Improved

quality

Ø Employee

participation

Ø Team work

Ø Working

relationships

Ø Customer

satisfaction

Ø Employee

satisfaction

Ø Productivity

Ø Communication

Ø Profitability

Ø Market

share

CONTRIBUTIONS

OF DEMING:

1.

Create and publish the Aims and Purposes of the

organization.

2.

Learn the New Philosophy.

3.

Understand the purpose of Inspection.

4.

Stop awarding business based on price alone.

5.

Improve constantly and forever the System.

6.

Institute Training.

7.

Teach and Institute Leadership.

8.

Drive out Fear, Create Trust and Create a climate

for innovation.

9.

Optimize the efforts of Teams, Groups and Staff

areas.

10.

Eliminate exhortations for the Work force.

11a. Eliminate numerical quotas for

the work force.

11b. Eliminate Management by

objectives.

12.

Remove Barriers that rob people of pride of

workmanship.

13.

Encourage Education and Self-improvement for

everyone.

14.

Take action to accomplish the transformation.

THE JURAN

TRILOGY

Juran

views quality as fitness for use.

Juran

Trilogy is designed to reduce the cost of quality over time.

1. QUALITY PLANNING

Ø Determine

internal & external customers.

Ø Their

needs are discovered.

Ø Develop

product / service features.

Ø Develop

the processes able to produce the product / service features.

Ø Transfer

plans to operations.

2. QUALITY CONTROL

Control

is used by operating forces to help meet the product, process and service

requirements.

It

consists of the following steps

1.

Determine items to be controlled.

2.

Set goals for the controls.

3.

Measure actual performance.

4.

Compare actual performance to goals.

5.

Act on the difference.

3.

QUALITY IMPROVEMENT

Aims to attain levels of performance that are higher than

current levels.

It

consists of the following steps

Ø Establishment

of quality council.

Ø Identify

the improvement projects.

Ø Establish

the project teams with a project leader.

Ø Provide

the team with the resources.

CONTRIBUTIONS

OF CROSBY:

The Four

absolutes of quality are

1. Quality

is defined as conformance to requirements.

2. The

system for causing Quality is prevention.

3. The

performance standard must be zero defects.

4. The

measurement of Quality is the Price of Nonconformance

Crosby’s

Fourteen Points:

1. Management

Commitment

2. Quality

Improvement Team

3. Quality

Measurement

4. Cost of

Quality Evaluation

5. Quality

Awareness

6. Corrective

Action

7. Establish

an Ad Hoc Committee for the Zero Defects Program

8. Supervisor

Training

9. Zero Defects

Day

10.Goal

Setting

11.Error

Cause Removal

12.Recognition

13.Quality

Councils

Do It Over Again

Related Topics