Chapter: Environmental Engineering : Collection and conveyence of water

Pumps And Pumping Stations

PUMPS AND PUMPING STATIONS

PURPOSE

I.

To

lift the water from source to the treatment plant which is at higher level

compared to the source

II.

To

lift the treated water to the elevated tanks

III.

To

increase the pressure in the distribution system.

IV. To lift the water at the treatment plant if

sufficient natural ground slope is not available as to cause gravitational flow

between different units of treatment plants.

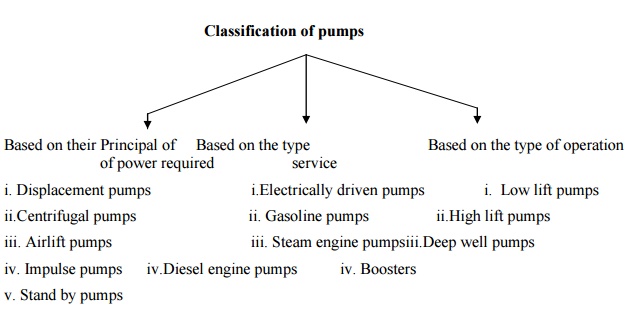

Classification of Pumps

Based

on their Principal of power required

i.

Displacement pumps

ii.Centrifugal

pumps

iii.

Airlift pumps

iv.

Impulse pumpsiv.Diesel engine pumps

v.

Stand by pumps

Based

on the type service

i.Electrically

driven pumps

ii.

Gasoline pumps

iii.

Steam engine pumps

iv.

Boosters

Based

on the type of operation

i. Low lift pumps

ii.High

lift pumps

iii.Deep

well pumps

Under most of the situations in

water supply scheme, displacement and centrifugal pumps are commonly used.

Displacement pumps

i.

Reciprocating

pumps

ii.

Rotary

pumps

PUMPING STATIONS

The

location of a pumping station is primarily governed by the place where it is to

recerive water. The points to be kept in mind while selecting a suitable site

are.

i.

The

site should be away from all the sources of contamination or pollution

ii.

The

site should be above the HFL of the river.

iii.

Its

future growth and expansion is easily possible

iv.

Possibility

of fire hazards is also to be considered

FACTORS AFFECTING THE SELECTION OF A PARTICULAR TYPE OF PUMP

1. Capacity of pumps

2. Importance of WSS

3. Initial cost of pumping arrangement

4. Maintenance cost

5. Space requirements for locating the

pumps

6. Number of units required

7. Total life of water required

8. Quantity of water to be pumped.

HEAD POWER AND EFFICIENCY OF PUMPS

The total head against which a pump

works is made up of

i.

The

suction Head(Hs)

ii.

The

Delivery Head(Hd)

iii.

The

Head loss due to friction entrance and exit in the rising main(Hf)

The suction HEAD is the difference

in elevation between the low water level and center line of pump.

Delivery HEAD is the difference in

elevation between the pump center line and point of discharge

Total HEAD (H) =Hs+Hd+Hf

The

work done by the pump in lifting „Q? cumecs of water by a head(H) =WQH kg-m/sec.

Where,

W = Specific weight of water, 1000

kg/m3 Q = discharge to be pumped, m3/sec.

The water horse power of the pump is

given by

WHP(out put) = WQH/75

If „n? is the efficiency of the pump

then

BRAKE HORSE POWER of the pump is given by

BHP(INPUT) + WQH/75n

ECONOMICAL DIAMETER OF THE RISING (PUMPING) MAIN

The

economical diameter is a particular size of the pumping or rising main which

while passing a given discharge of water gives the total annual expense to be

minimum.

If the diameter chosen is more than

the economic dia, it will lead to higher cost of the pipe line on the other

hand, if the dia of the pipe is less than the economical dia, the increased

velocity will lead to higher friction headless and require more HP for the

required pumping and the cost of pumping shall be much more than the resultant

saving in the pipe cost.

LEA FORMULA

An empirical formula given by LEA

Connecting the dia and discharge is

given by

D

= 0.97 to 1.22 ![]() SqRt(Q)

SqRt(Q)

Where

D = economical diain m

Q = Discharge to be pumped in cusecs

This relation gives optimum flow

velocity varying between 0.8 to 1.35m/sec

FOR

RIGOROUS ANALYSIS The

total cost of pipe and pumping should be woeked out at different assumed velocities (b/w 0.8 to 1.8m/sec) and a graph

plotted between the annual cost and the size of the pipe. The economical size

is one which gives the least annual cost.

Related Topics