Chapter: Mechanical : Engineering Economics & Cost Analysis : Introduction to Economics

Process Planning /Process Modification

Process Planning /Process Modification

While planning for a new component, a feasible sequence of operations with the least cost of processing is to be considered.

The process sequence of a component which has been planned in the past is not static.

It is always subject to modification with a view to minimize the cost of manufacturing the component.

So, the objective of process planning/process modification is to identify the most economical sequence of operations to produce a component.

The steps in process planning are as follows:

1. Analyze the part drawing to get an overall picture of what is required.

2. Make recommendations to or consult with product engineers on product design changes.

3. List the basic operations required to produce the part to

the drawing or specifications.

4. Determine the most practical and economical manufacturing method and the form or tooling required for each operation.

5. Devise the best way to combine the operations and put them in sequence.

6. Specify the gauging required for the process.

Steps 3–5 aim to determine the most practical and economical sequence of operations to produce a component. This concept is demonstrated with a numerical problem.

Example

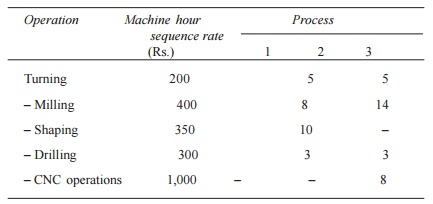

The process planning engineer of a firm listed the sequences of operations as shown in Table to produce a component.

Table Data for Example

Sequence

Process sequence

1 Turning – Milling – Shaping – Drilling

2 Turning – Milling – Drilling

3 All operations are performed with CNC machine

The details of processing times of the component for various operations and their machine hour rates are summarized in Table below

Machine Hour Rates and Processing Times (minutes) for Example

Find the most economical sequence of operations to manufacture the component.

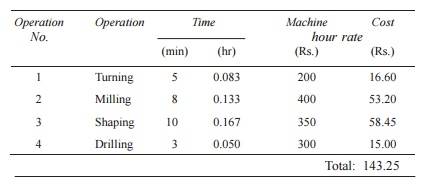

Solution (a) Cost of component using process sequence 1. The process sequence 1 of the component is as follows:

Turning – Milling – Shaping – Drilling

The calculations for the cost of the above process sequence are summarized in Table.

Table Workings for Process Sequence 1

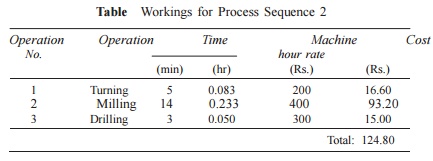

(b) Cost of component using process sequence 2. The process sequence 2 of the component is as follows:

Turning – Milling – Drilling

The calculations for the cost of the above process sequence are given in Table

Table Workings for Process Sequence 2

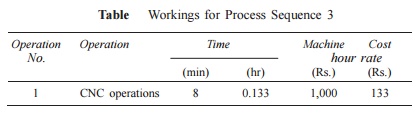

(c) Cost of component using process sequence 3. The process sequence 3 of the component is as follows:

Only CNC operations

The calculations for the cost of the above process sequence are summarized in Table

Table Workings for Process Sequence 3

The process sequence 2 has the least cost. Therefore, it should be selected for manufacturing the component.

Related Topics