Chapter: Civil Engineering : Surveying and Civil Engineering Materials

Plain and Green concrete

PLAIN CONCRETE

Major ingredients of concrete are:

Functions of Various Ingredients

Properties of Green concrete

Tests on Concrete

PLAIN CONCRETE

Plain concrete,

commonly known as concrete, is an intimate mixture of binding material, fine

aggregate, coarse aggregate and water. This can be easily moulded to desired

shape and size before it looses plasticity and hardens. Plain concrete is

strong in compression but very weak in tension. The tensile property is

introduced in concrete by inducting different materials and this attempt has

given rise to RCC, RBC, PSC, FRC, cellular concrete and Ferro cement. In this

chapter proportioning, mixing, curing, properties, tests and uses of plain

concrete is dealt in detail. The other improved versions of concrete are

explained and their special properties and uses are pointed out.

Major ingredients of concrete are:

1. Binding material (like cement, lime, polymer)

2. Fine aggregate (sand)

3. Coarse aggregates (crushed stone, jelly)

4. Water.

A small quantity of admixtures like air

entraining agents, water proofing agents, workability agents etc. may also be

added to impart special properties to the plain concrete mixture.

Depending upon the

proportion of ingredient, strength of concrete varies. It is possible to

determine the proportion of the ingredients for a particular strength by mix

design procedure.

.In proportioning of concrete it is kept in mind

that voids in coarse aggregates are filled with sand and the voids in sand are

filled with cement paste.

Functions of Various Ingredients

Cement is the binding material. After addition

of water it hydrates and binds aggregates and the surrounding surfaces like

stone and bricks. Generally richer mix (with more cement) gives more strength.

Setting time starts after 30 minutes and ends after 6 hours. Hence concrete

should be laid in its mould before 30 minutes of mixing of water and should not

be subjected to any external forces till final setting takes place.

Coarse aggregate consists of crushed

stones. It should be well graded and the stones should be of igneous origin.

They should be clean, sharp, angular and hard. They give mass to the concrete

and prevent shrinkage of cement. Fine aggregate consists of river sand. It

prevents shrinkage of cement. When surrounded by cement it gains mobility

enters the voids in coarse aggregates and binding of ingradients takes place.

It adds density to concrete, since it fills the voids. Denser the concrete

higher is its strength.

Water used for making concrete

should be clean. It activates the hydration of cement and forms plastic mass.

As it sets completely concrete becomes hard mass. Water gives workability to

concrete which means water makes it possible to mix the concrete with ease and

place it in final position. More the water better is the workability.

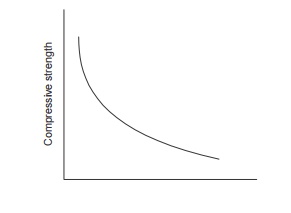

However excess water reduces the

strength of concrete. Figure 1.1.13.1 shows the variation of strength of

concrete with water cement ratio. To achieve required workability and at the

same time good strength a water cement ratio of 0.4 to 0.45 is used, in case of

machine mixing and water cement ratio of 0.5 to 0.6 is used for hand mixing.

Water/cement ratio

Properties of Green concrete

1.Workability: This is defined as the ease with which concrete can be compacted

fully without seggregating and bleeding. It can also be defined as the

amount of internal work required to fully compact the concrete to optimum

density. The workability depends upon the quantity of water, grading, shape and

the percentage of the aggregates present in the concrete.

Workability is measured by

(a) The

slump observed when the frustum of the standard cone filled with concrete is

lifted and removed.

(b) The

compaction factor determined after allowing the concrete to fall through the

compaction testing machine.

(c) The time

taken in seconds for the shape of the concrete to change from cone to cylinder

when tested in Vee-Bee consistometer.

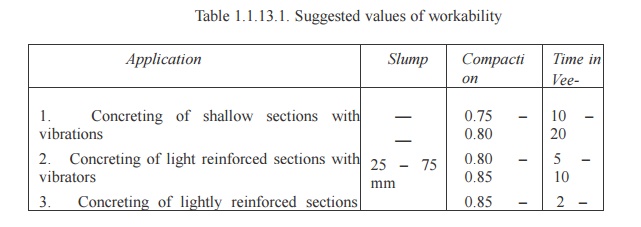

The suggested

values of workability for different works are as shown in Table 1.1.13.1.

Table 1.1.13.1. Suggested values of workability

2. Segregation: Separation of coarse particles from the green concrete is

called segregation. This may happen due to lack of sufficient quantity

of finer particles in concrete or due to throwing of the

concrete from greater heights at the time of

placing the concrete. Because of the segregation, the cohesiveness of the

concrete is lost and honey combing results. Ultimately it results in the loss

of strength of hardened concrete. Hence utmost care is to be taken to avoid

segregation.

3. Bleeding: This refers to the appearance

of the water along with cement particles on the surface of the freshly

laid concrete. This happens when there is excessive quantity of water in the

mix or due to excessive compaction. Bleeding causes the formation of pores and

renders the concrete weak. Bleeding can be avoided by suitably controlling the

quantity of water in the concrete and by using finer grading of aggregate

4.

Harshness: Harshness is the resistance offered by concrete to its surface

finish. Harshness is due to presence of lesser quantity of fine

aggregates, lesser cement mortar and due to use of poorely graded aggregates.

It may result due to insufficient quantity of water also. With harsh concrete

it is difficult to get a smooth surface finish and concrete becomes porous.

Tests on Concrete

The following are

some of the important tests conducted on concrete:

2. Compaction factor test.

3. Crushing strength test.

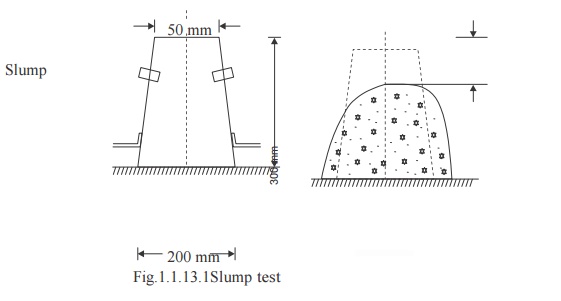

1. Slump Test:

This test is conducted to determine the workability of concrete. It needs a

slump cone for test (Fig. 3.3). Slump cone is a vessel in the shape of a

frustum of a cone with diameter at bottom 200 mm and 50 mm at top and 300 mm

high. This cone is kept over a impervious platform and is filled with concrete

in four layers.

Each layer is

tamped with a 16 mm pointed rod for 25 times. After filling completely the cone

is gently pulled up. The decrease in the height of the concrete is called

slump. Higher the slump, more workable is the concrete. The desired values of

slumps for variousworks have been shown in Table 1.1.13.1

Fig.1.1.13.1 Slump test

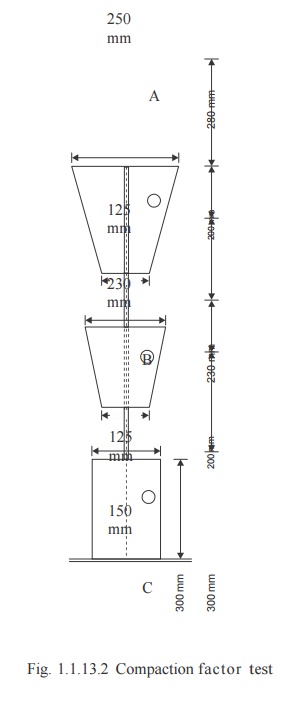

2. Compaction Factor Test: This is another test to identify the workability of concrete.

This test is conducted in the laboratory. The test equipment consists of

two hoppers and a cylinder fixed to a stand, the dimensions and the distances

between the three vessels being standardized. Vessel A and B are having hinged

bottoms whereas cylinder C is having fixed bottom. [Ref. Fig. 1.1.13.2]

Top vessel A is filled with the

concrete to be tested. As soon as it is filled, the hinged door is opened.

Concrete is collected in vessel B. Then the hinged door of B is opened to

collect concrete in cylinder C. The concrete in cylinder C is weighted. Let it

be W1.

Now cylinder is

again filled with the sample of concrete in 50 mm layers, which is compacted by

ramming and vibrating. Then the weight of compacted concrete is determined. Let

this weight be W2.

The ratio W1/W2

is termed as compaction factor. The specified values of compaction factor for

different works are already listed in Table 3.2.

Fig. 1.1.13.2 Compaction factor test

Crushing Strength

Test: Metallic moulds of size 150 mm × 150 mm × 150 mm are used for casting

concrete cubes. Before filling mould, it is properly oiled on its inner

surfaces, so that cubes can be easily separated. Fresh cube is filled with

concrete to be tested in 3 layers and kept in the room. After 24 hours, cube is

removed from the mould and kept under water for curing. After 28 days of curing

cubes are tested in the compression testing machine. In this test cubes are

placed over the smooth surface which is in contact with side plates of mould.

The crushing load is noted and crushing strength is found as

load divided by

surface area (150 × 150 mm2). Code

specify the desirable strength of concrete for 3 days and 7 days for quick

assessment of strength of concrete.

Desirable Properties Concrete

Appropriate quality and quantity of cement, fine

aggregate, coarse aggregate and water should be used so that the green concrete

has the following properties:

(a) Desired workability

(b) No seggregation in

transporting and placing (c) No bleeding and

(d) No harshness

Related Topics