Chapter: Civil Engineering : Surveying and Civil Engineering Materials

Bricks

Bricks

1 Properties of Bricks

2 Tests on Bricks

3 Classification of Bricks Based on their Quality

4 Uses of Bricks

Bricks

Brick is obtained by moulding good clay into a

block, which is dried and then burnt. This is the oldest building block to

replace stone. Manufacture of brick started with hand moulding, sun drying and

burning in clamps. A considerable amount of technological development has taken

place with better Knowledge about to properties of raw materials, better

machineries and improved techniques of moulding drying and burning.

The size of the bricks are of 90 mm

× 90 mm × 90 mm and 190 mm × 90 mm × 40 mm. With mortar joints, the size of

these bricks are taken as 200 mm × 100 mm × 100 mm and 200 mm × 100 mm

(i) Building Bricks: These bricks are used for the construction of walls.

(ii) Paving Bricks: These are vitrified bricks and are used as pavers.

(iii) Fire Bricks: These bricks are specially made to withstand furnace

temperature. Silica bricks belong to this category.

(iv) Special Bricks: These bricks are different from the commonly used building bricks

with respect to their shape and the purpose for which they are made. Some of

such bricks are listed below:

(a) Specially shaped bricks

(b) Facing bricks

(c)Perforated building bricks

(d) Burnt clay hollow bricks

(e) Sewer bricks

( f ) Acid resistant bricks

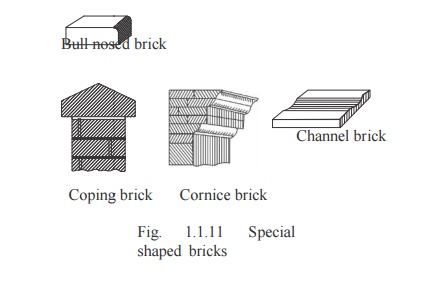

(a) Specially

Shaped Bricks: Bricks of special shapes are

manufactured to meet the requirements of different situations. Some of

them are shown in Fig. 1.1.11.

(b) Facing

Bricks: These bri cks are used in the outer

face of masonry. Once these bricks are provided, plastering is not

required. The standard size of these bricks is 190 × 90 × 90 mm or 190 × 90 ×

40 mm.

(c) Perforated Building Bric

ks: These bricks are manufactured with area of perforation of

30 to 45 per cent.

The area of each perforation should not exceed 500 mm2. T he

perforation should be uniformly distribute d over the surface.

They are manufactured in the size 190× 190 × 90

mm and 290 × 90 × 90 mm

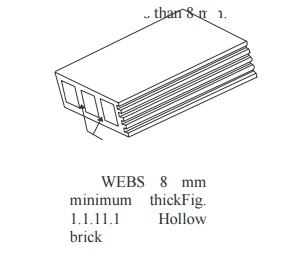

(d) Burn’t Clay Hollow Brick s: Figure 1.1.11.1 shows a burnt clay

hollow b rick. They are light in weight. They are used for the

construction of partition walls. They provide good thermal insulation to buildi

ngs. They are manufactured in the sizes 190 × 190 × 90 mm,290 × 90 × 90 mm and

290 × 140 × 90 mm. The thickness of any shell should not be less than 11 mm and

that of anny web not less than 8 mm.

WEBS 8

mm minimum thick

Fig. 1.1.11.1 Hollow brick

(e) Sewer

Bricks: These bricks are used for the

construction of sewage li nes. They are manufactured from surface cl ay,

fire clay shale or with the combination of th ese. They are manufactured in the

sizes 190 × 90 × 90 mm and 190 × 90 × 40 mm. The av erage strength of these

bricks should be a m inimum of 17.5 N/mm2 . The water absorption

should not be more than 10 per cent.

( f ) Acid

Resistant Bricks: These bricks are used for

floorings likely to be subjected to acid attacks, lining of chambers in

chemical plants, lining of sewers carrying industrial wastes etc. These bricks

are made of clay or shale of suitable composition with low lime and iron

content, flint or sand and vitrified at high temperature in a ceramic kiln.

Properties o

f Bricks

The following are the required

properties of good Bricks:(i) Colour: Colour should be uniform

and bright.

(ii) Shape: Bricks should have plane faces. They should have sharp and true

right angled corners.

(iii) Size: Bricks should be of standard sizes as prescribed by codes.(iv)

Texture: They should possess fine, dense and uniform texture. They

should not possess fissures, cavities, loose grit and unburnt lime.

(v)

Soundness: When struck with hammer or with

another brick, it should produce metallic

sound.

(vi) Hardness: Finger scratching should not produce any impression on the

brick.

(vii)

Strength: Crushing strength of brick should not be less

than 3.5 N/mm2. A field test for strength is that when

dropped from a height of 0.9 m to 1.0 mm on a hard ground, the brick should not

break into pieces.

(viii) Water

Absorption: After immercing the brick in water

for 24 hours, water absorption should not be more than 20 per cent by

weight. For class-I works this limit is 15 per cent.

(ix)

Efflorescence: Bricks should not show white

patches when soaked in water for 24 hours and then allowed to dry in

shade. White patches are due to the presence of sulphate of calcium, magnesium

and potassium. They keep the masonry permanently in damp and wet conditions.

(x) Thermal Conductivity: Bricks should have low thermal conductivity, so that buildings

built with them are cool in summer and warm in winter.

(xi) Sound Insulation: Heavier bricks are poor insulators of sound while light weight

and hollow bricks provide good sound insulation.

(xii) Fire Resistance: Fire resistance of bricks is usually good. In fact bricks are

used to encase steel columns to protect them from fire

Tests on Bricks

The following laboratory

tests may be conducted on the bricks to find their suitability:

(i) Crushing strength

(ii) Absorption

(iii) Shape and size

and

(iv) Efflorescence.

(i)

Crushing Strength: The brick specimen are immersed in water

for 24 hours. The frog of the brick is filled flush with 1:3 cement mortar and

the specimen is stored in damp jute bag for 24 hours and then immersed in clean

water for 24 hours. The specimen is placed in compression

testing machine with 6 mm plywood on top

and bottom of it to get uniform

load on the

specimen. Then load is applied axially at a uniform rate of 14 N/mm2

. The crushing load is noted. Then the crushing strength is the ratio of

crushing load to the area of brick loaded. Average of five specimen is taken as

the crushing strength.

(ii) Absorption Test: Brick specimen are weighed dry. Then they are immersed in water

for a period of 24 hours. The specimen are taken out and wiped with cloth.

The weight of each specimen in wet

condition is determined. The difference in weight indicate the water absorbed.

Then the percentage absorption is the ratio of water absorbed to dry weight

multiplied by 100. The average of five specimen is taken. This value should not

exceed 20 per cent.

iii) Shape and Size: Bricks should be of

standard size and edges should be truely rectangular with sharp

edges. To check it, 20 bricks are selected at random and they are stacked along

the length, along the width and then along the height. For the standard bricks

of size 190 mm × 90 mm × 90 mm. IS code permits the following limits:

|

Lengthwise: |

3680 |

to |

3920mm |

|

Widthwise: |

1740 |

to |

1860mm |

|

Heightwise: |

1740 |

to |

1860mm |

The following field

tests help in acertaining the good quality bricks:

(i)

uniformity in size (ii) uniformity in colour

(iii) structure

(iv) hardness test

(v) sound test

(vi) strength test.

(i) Uniformity in Size:

A good brick should have rectangular plane surface and uniform

in size. This check is made in the field by observation.

(ii) Uniformity in Colour:

A good brick will be having uniform colour throughout. This

observation may be made before purchasing the brick.

(iii) Structure: A few bricks may be broken in the field and their cross-section

observed. The section should be homogeneous, compact and free from defects

such as holes and lumps.

(iv) Sound Test: If two bricks are struck with each other they should produce

clear ringing sound. The sound should not be dull.

(v) Hardness Test:

For this a simple field test is scratch the brick with nail. If no impression

is marked on the surface, the brick is sufficiently hard

(vi) Efflorescense: The presence

of alkalies in brick is not desirable because they form patches of gray

powder by absorbing moisture. Hence to determine the presence of alkalies this

test is performed as explained below:

Place the brick specimen in a glass

dish containing water to a depth of 25 mm in a well ventilated room. After all

the water is absorbed or evaporated again add water for a

depth of 25 mm. After second evaporation observe

the bricks for white/grey patches. The observation is reported as ‘nil’, ‘slight ‘moderate’, ‘heavy’ or serious

to mean

(a) Nil: No patches

(b) Slight: 10% of area covered with deposits

(c) Moderate: 10 to 50% area

covered with deposit but unaccompanied by flaking of the surface. (d)

Heavy: More than 50 per cent area covered with deposits but unaccompanied by

flaking the surface.

(e) Serious: Heavy deposits of salt accompanied by

flaking of the surface.

Classification of Bricks Based on their Quality

The bricks used in construction are

classified as:

(i) First class bricks (ii)

Second class bricks

(iii) Third class bricks and

(iv) Fourth class bricks

(i) First Class Bricks: These bricks are of standard shape and size. They are burnt in

kilns. They fulfill all desirable properties of bricks.

(ii) Second Class Bricks: These bricks are ground moulded and burnt in kilns. The edges

may not be sharp and uniform. The surface may be some what rough. Such

bricks are commonly used for the construction of walls which are going to be

plastered.

(iii) Third Class Bricks: These

bricks are ground moulded and burnt in clamps. Their edges are somewhat

distorted. They produce dull sound when struck together. They are used for

temporary and unimportant structures.

(iv) Fourth Class Bricks: These are the over burnt bricks. They are dark in

colour. The shape is irregular. They are used as aggregates for concrete

in foundations, floors and roads.

Uses of Bricks

Bricks are used in the following

civil works:

(i) As building blocks.

(ii) For lining of ovens, furnaces and

chimneys. (iii) For protecting steel columns from fire.

(iv) As aggregates in providing water

proofing to R.C.C. roofs. (v) For pavers for footpaths and cycle tracks.

(vi) For lining sewer lines.

Related Topics