Chapter: Chemistry : Phase Rule and Alloys

Phase Rule and Alloys

PHASE RULE AND ALLOYS

Chemical reactions are of two types

1.Irreversible

reaction

2. Reversible reaction – it’s of two types

a. homogeneous

b. heterogeneous

A.

homogeneous reversible reaction

B.heterogeneous reversible reaction

--- its behaviour can be studied by PHASE

RULE given by Willard Gibbs (1874).

Phase rule

The

number of degree of freedom (F) of the system is related to number of

components (C) and number of phases (P) by the following phase rule equation.

F = C-P+2

Explanation or meaning of terms 1. Phase

(P)

Any

homogeneous physically distinct and mechanically separable portion of a system

which is separated from other parts of the system by definite boundaries.

a.

Gaseous phase

All gases are completely miscible and there is

no boundary between one gas and the other. For example: air – single phase

b.Liquid

phase

It depends on the number of liquids present and

their miscibilities.

i.

If two

liquids are immiscible, they will form three separate phases two liquid phase

and one vapour phase. For example: benzene-water.

ii.

If tow

liquids are miscible, they will form one liquid phase and one vapour phase. For

example: alcohol – water.

C .Solid

phase

Every solid constitutes a separate phase

For

example:

(i)

Water system ------- three phases

(ii)

Rhombic sulphur (s) -- > monoclinic sulphur (s) ----- two phase

iii)

Sugar solution in water ----- one phase

iv) CuSO4.5H2O(s) < -- -- > CuSO4.3H2O(s)

+ 2H2O(g) ---- three phases.

2.

Component (C)

“The

smallest number of independently variable constituents, by means of which the omposition

of each phase can be expressed in the form of a chemical equation”.

For

example:

i) Water system ---- one component ( H2O )

ii) An aqueous system of NaCl --- two

component ( NaCl , H2O )

iii) PCl5(s) < -- -- > PCl3

(l) + Cl2 (g) --- two

component ,three phases

iv) CuSO4.5H2O(s) < -- -- > CuSO4.3H2O(s) + 2H2O(g) ---- three phases,two

3. Degree

of freedom(F)

“The minimum number of independent variable factors such as

temperature, pressure and concentration, which much be fixed in order to define

the system completely”.

i) Water system

Ice (s)

< -- -- > water (l) < -- -- > vapour (g)

F = Non

variant (or) zero variant

ii) Ice (s) < -- -- > water (l)

F =

univariant (one)

iii) For

a gaseous mixture of N2 and H2, we must state both the pressure and

temperature.

Hence,the

system is bivariant.

PHASE DIAGRAM:

Phase diagram is a graph obtained by plotting

one degree of freedom against another.

Types of phase diagrams

(i)P-T

Diagram : used for one component system

(ii) T-C Diagram : used for two component system

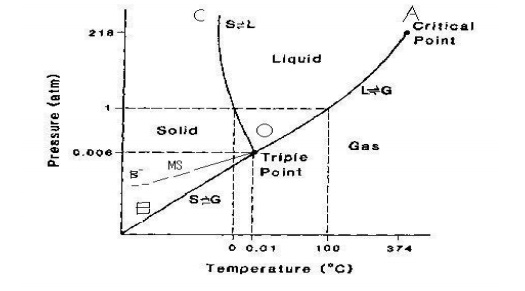

APPLICATIONS OF PHASE RULE TO ONE COMPONENT

SYSTEM The water system:

Water exists in three possible phases namely

solid, liquid and vapour. Hence there

can be

three forms of equilibria.

Solid < -- -- > Liquid

Liquid < -- -- > Vapour

Solid < -- -- > Vapour

Each of

the above equilibrium involves two phases. The phase diagram for the water

system is shown in the figure.

This

phase diagram contains curves, areas,

and triple.

(i)Curve OA

The

curve OA is called vaporisation curve, it represents the equilibrium between

water and vapour. At any point on the curve the following equilibrium will

exist.

Water < -- -- > Water vapour

The degree of freedom of the system is one,

i.e, univariant.

This is predicted by the phase rule.

F=C-P+2;

F=1-2+2; F=1

This

equilibrium (i.e. Line OA) will extend up to the critical temperature (347o

C). Beyond the critical temperature the equilibrium will disappear only water

vapour will exist.

(ii) Curve OB

The

curve OB is called sublimation curve of ice, it represents the equilibrium

between ice and vapour. At any point on the curve the following equilibrium

will exist.

ICE <

-- -- > VAPOUR

The degree of freedom of the system is one, i.e. univariant. This is predicted by the

phase rule.

F = C –

P + 2; F = 1-2=2 ; F=1

This

equilibrium (line OB) will extend up to the absolute zero (-273o C),

where no vapour can be present and only ice will exist.

iii) Curve OC

The

curve OC is called melting point curve of ice, it represents the equilibrium

between the ice and water. At any point on the curve the following equilibrium

will exist.

Ice < -- -- > water

The

curve OC is slightly inclined towards pressure axis. This shows that melting

point of ice decreases with increase of pressure.

The

degree of freedom of the system is one i.e., univariant. iv) point O

(triple point)

The

three curves OA ,OB ,OC meet at a point “O” ,where three phases namely solid

,liquid and vapour are simultaneously at equilibrium .

This

point is called triple point, at this point the following equilibrium will

exist.

Ice < -- -- > water < -- -- > vapour

![]()

![]() The degree of freedom of the system is zero i.e., nonvariant.This is predicted by the

phase rule. F=C-P+2; F=1-3+2=0

The degree of freedom of the system is zero i.e., nonvariant.This is predicted by the

phase rule. F=C-P+2; F=1-3+2=0

Temperature

and pressure at the point “O” are 0.0075 oC and 4.58 mm

respectively.

(v) Curve OB’: Metastable equilibrium

The

curve OB’ is called vapour pressure curve of the super-cool water or metastable

equilibrium where the following equilibrium will exist.

Super-cool water < -- -- > vapour

Sometimes

water can be cooled below O oC without the formation of ice, this

water is called super –cooled water. Super cooled water is unstable and it can

be converted in to solid by seeding or by slight disturbance.

vi) Areas

Area

AOC, BOC, AOB represents water, ice and vapour respectively .The degree of the

freedom of the system is two.i.e. Bivariant.

This is

predicted by the phase rule

F=C-P=2; F=1-1+2; F=2

Two component alloy system or multi component

equilibria Reduced phase rule or condensed system

The system in which only the solid and liquid are considered and

the gas phase is ignored is called a condensed system.since pressure kept

constant, the phase rule becomes

F’ = C –

P + 1

This

equation is called reduced phase rule.

Classification of two component system

Based on

the solubility and reactive ablity, the two component systems are classified in

to three types.

1. Simple

eutectic formation - A

binary system consisting of two substances, which are completely miscible in the liquid state, but completely immiscible

in the solid state, is known as eutectic (easy melt) system. They do not react

chemically. Of the different mixtures of the two substances, the mixture having

the lowest melting point is known as the eutectic mixture.

2. a) formation of compound with congruent melting

point

b) Formation of compound with incongruent melting

point

3. Formation of solid solution

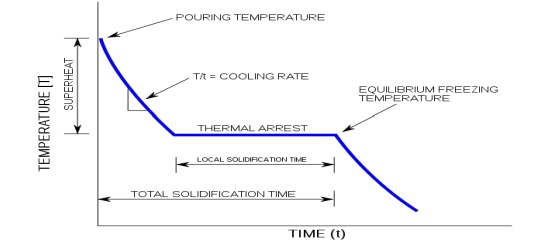

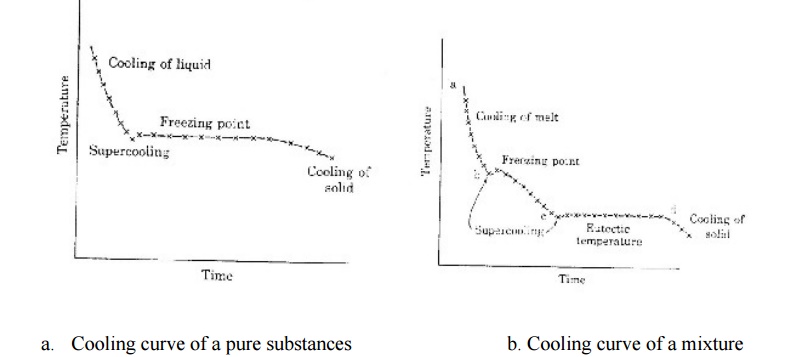

Thermal analysis or cooling curve

Thermal analysis is a method involving a study of the cooling

curves of various compositions of a system during solidification. The form of

the cooling curve indicates the composition of the solid.

Ex: 1.

Cooling curve of a pure solid. Ex: 2. Cooling curve of a mixture A + B.

A cooling curve is a line graph

that represents the change of phase of matter, typically from a

gas to a solid or a liquid to a solid.

The

independent variable (X-axis) is time and the dependent variable (Y-axis) is

temperature. Below is an example of a cooling curve.

The

initial point of the graph is the starting temperature of the matter, here

noted as the "pouring temperature". When the phase change occurs

there is a "thermal arrest", that is the temperature stays constant.

This is because the matter has more internal energy as a liquid or gas than in the state that it is cooling to. The amount of

energy required for a phase change is known as latent heat. The

"cooling rate" is the slope of the cooling curve at any point.

A Pure substance in the fused or liquid state is allowed to cool

slowly. The temperature is noted at different times.when represented

graphically the rate of cooling will be a continuous from ‘a’ to ‘b’.

When the

freezing point is reached and solid making its appearance there will be a break

in the continuity of the cooling curve.The temperature will thereafter remain

constant until the liquid is completely solidified.Thereafter the fall in

temperature wil again become continuous.

a. Cooling curve of a pure substances b. Cooling curve of a mixture

If a mixture of two solids in the fused state is cooled

slowly we get a cooling curve .

Here

also first a continuous coling curve will be obtained as long as the mixture is

in the liquid state .

When a

solid phase begins to form there will be a break in the cooling curve .But the

temperature will not remain constant unlike in the case of cooling of a

purified substance.The temperature will decrease continuously but at a

different rate.The fall of temperature will continue till the mixture forms a

eutectic and the eutectic point is reached.

The

temperature will thereafter remain constant until solidification is complete .

Thereafter the fall of temperature will become uniform ,but the rate of fall

will be different from that for a pure substance.

Uses of cooling curves

i)

Percentage

purity of the compounds can be noted from the cooling curve.

ii)

The

behaviour of the compounds can be clearly understood from the cooling curve.

iii)

The

procedure of thermal analysis can be used to derive the phase diagram of any

two

component system.

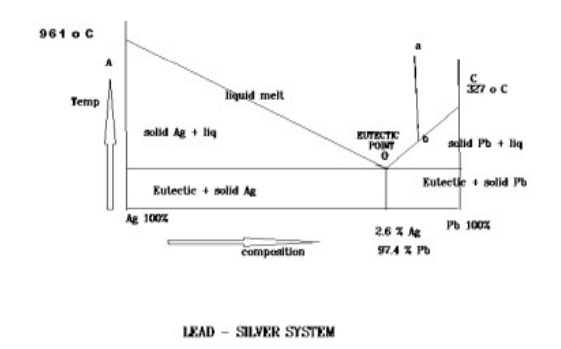

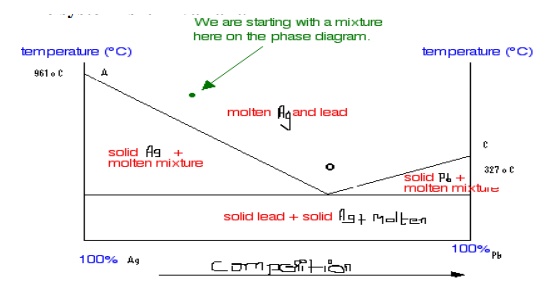

BINARY ALLOY SYSTEM OR THE SIMPLE EUTECTIC

SYSTEM The Lead – Sliver system

Since the system is studied at constant

pressure,the vapour phase is ignorned and the condensed phase rule is rule is

used.

F I= C-P+1

The phase diagram of lead –sliver system is

shown in the figure It contains lines,areas and the eutectic point.

i) curve AO

The

curve AO is known as freezing point curve of sliver.

Along

the curve AO, solid Ag and the melt are in equilibrium.

Solid Ag

< -- -- > melt

According

to reduced phase rule

F’=C-P+1

C=2

P=2

F’=1

The

system is univariant

ii) curve BO

The

curve BO is known as freezing point curve of lead .

Along

the curve BO, solid Pb and the melt are in equilibrium.

Solid

Pb < -- -- > melt

According

to reduced phase rule

F’=C-P+1

C=2

P=2

F’=1

The

system is univariant.

iii) Point “ O ” (eutectic point)

The

curves AO and BO meet at point ‘ O ‘ at a temperature of 303 o C ,where the

three phases are in equilibrium.

Solid Pb

+ soild Ag < -- -- > melt

According

to reduced phase rule

F’=C-P+1

C=2

P=3

F’=1

The

system is non-variant.

The

point “ O “ is called eutectic point or eutectic temperature and is

corresponding composition,97.4 % Pb and 2.6 % Ag ,is called eutectic composition.below

this point the eutectic compound and the metal solidfy.

iv) Areas

The area

above the line AOB has a single phase( molten Pb + Ag ). According to reduced

phase rule

F’=C-P+1

C=2

P=1

F’=2

The

system is bi-variant.

The area

below the line AO ,OB and point “O” have two phases and hence the system is

univariant.

According

to reduced phase rule F’=C-P+1

C=2

P=2

F’=1

The

system is uni-variant.

The process of raising the relative proportion

of Ag in the alloy is known as pattinson’s process.

The Pattinson process was patented

in 1833. It depended on well-known material properties; essentially that lead

and silver melt at different temperatures. The equipment consisted of a row of

about 8-9 iron pots, which could be heated from below. Agentiferous lead was

charged to the central pot and melted. This was then allowed to cool, as the

lead solidified, it was skimmed off and moved to the next pot in one direction,

and the remaining metal was then transferred to the next pot in the opposite

direction. The process was repeated in the pots successively, and resulted in

lead accumulating in the pot at one end and silver in that at the other. The

process was economic for lead containing at least 250 grams of silver per ton.

Uses of

eutectic system

1.suitable

alloy composition can be predicted with the help of eutectic systems.

2.eutectic systems are used in preparing solders ,used for joining two metal

pieces together.

Melting point

It is

the temperature at which the solid and liquid phases, having the same

composition ,are in

equilibrium.

Solid

A < -- -- > solid B

Eutectic point

It is

the temperature at which two solids and a liquid phase are in equilibrium.

Solid A

+ solid B < -- ---> Liquid

Triple point

It is

the temperature at which three phases are in equilibrium.

Solid < -- ---> liquid

< -- ---> vapour

![]() By definition ,

By definition ,

All the

eutectic points are melting points, but all the melting points need not be

eutectic points. ll ly , all the eutectic points are triple points

,but all the triple points need not be eutectic points.

Uses (or) merits of phase rule

1. It is a convenient method of

classifying the equilibrium states in terms of phases ,components and degree of

freedom.

2. It

helps in deciding whether the given number of substances remain in equilibrium

or not.

Limitations of phase rule

1.phase

rule can be applied for the systems in equilibrium.

2.only

three variables like P,T & C are considered ,but not electrical, magnetic

and gravitational forces.

Definition

An alloy is defined as “homogeneous solid

solution of two or more different element one of which at least is essentially

a metal”. Alloy containing Hg as a constituent element are called amalgams.

Properties

of alloys

1)

Alloy

are harder less malleable and possess lower melting point than their component

metals

2)

Alloys

possess low electrical conductivity

3)

Alloys

resist corrosion and the action of acids

Importance

or need of making alloys

1.

To increase the hardness of the metal Example

Gold and silver are soft metal they are alloyed

with copper to make them hard

2. To

lower the melting points of the metal Example

Wood metal (an alloy of lead, bismuth, tin and

cadmium) melts at 60.5⁰c which is far below the melting points of any

of these constituent metals

3. To resist the corrosion of the metal

Example

Pure iron rested but when it is alloyed with

carbon chromium (stainless steel) which resists corrosion

4. To

modify chemical activity of the metal

Example

Sodium amalgam is less active than sodium but

aluminium amalgam is more active than aluminium

5. To

modify the colour of the metal Example

Brass an alloy of copper (red) and size

(silver-white) is white colour.

6. To

get good casting of metal Example

An alloy of lead with 5% tin and 2% antimony is

used fro casting printing type due toits good casting property

Functions

(or) effects of alloying elements

Addition of small amount of certain metals such

as Ni, Cr, Mo, Mn, Si, v and Al impart special properties like hardness,

tensile strength, resistance to corrosion and coefficient of expansion on

steel. Such products are known as special steel or alloy steels Some important

alloying element and their functions are given in table

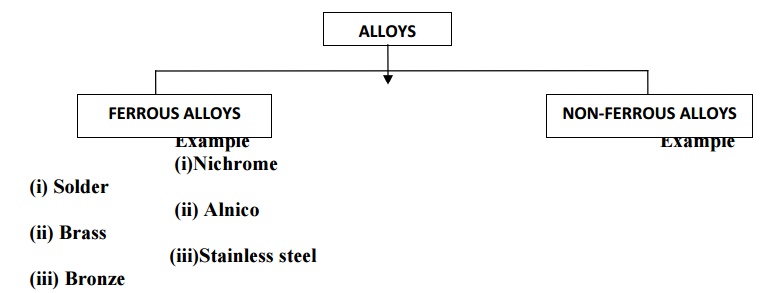

CLASSIFICATION (OR) TYPES OF ALLOYS

FERROUS ALLOYS OR ALLOY STEELS

Ferrous alloys are the type of steels in which

the elements like Al,B,Cr,Co,Cu,Mn are present in sufficient quantities, in

addition to carbon & iron.

PROPERTIES

1. High yield point & strength

2. Sufficient formability,ductility &

weldability

3. Corrosion & abrasion resistant

4. Less distortion & cracking

5. High temperature strength

IMPORTANT FERROUS ALLOYS (i)NICHROME

Nichrome is an alloy of nickel & chromium

COMPOSITION

Nickel –

60%

Chromium

– 12%

Iron –

26%

Manganese

– 2%

PROPERTIES

1. Good resistance to oxidation & heat

2. High melting point & electrical resistance

3. Withstand heat up to 1000-1100⁰C

USES

1. Used for making resistance coils,heting

elements in stoves & electric irons

2. Used in making parts of boilers,steam lines

stills,gas turbines,aero engine valves,retorts,annealing boxes.

(ii)ALNICO

Alnico is an alloy of aluminium-nickel-cobalt .

COMPOSITION

Aluminium

– 8-12%

Nickel –

14-28%

Cobalt –

5-35%

PROPERTIES

1. Excellent magnetic properties & high

melting point

2. Magnetized to produce strong magnetic fields as

high as 1500 gauss

TYPES OF

ALNICO ALLOYS

Alnico alloys are of two types

1. ISOTROPIC ALNICO

It is effectively magnetized in any direction

2.ANISOTROPIC

ALNICO

It possess preffered direction of magnetization.

Anisotropic alnico possesses greater magnetic

capacity in their preffered orientation than isotropic alnico.

USES

1. Used as permanent magnets in

motors,generators,radio speakers microphones,telephone receivers &

galvanometers.

(iii)STAINLESS

STEELS (or)CORROSIOPN RESISTANT STEELS

· These are alloy steels containing chromium together with other elements such

as nickel,molybdenum,etc.

· Chromium-16%

or more

· Carbon-0.3-1.5%

PROPERTIES

1. Resist corrosion by atmospheric gases &

also by other chemicals.

2.

Protection against corrosion is due to the

formation of dense, non-porous,tough film of chromium oxide at the metal

surface. If the film cracks, it gets automatically healed up by atmospheric

oxygen

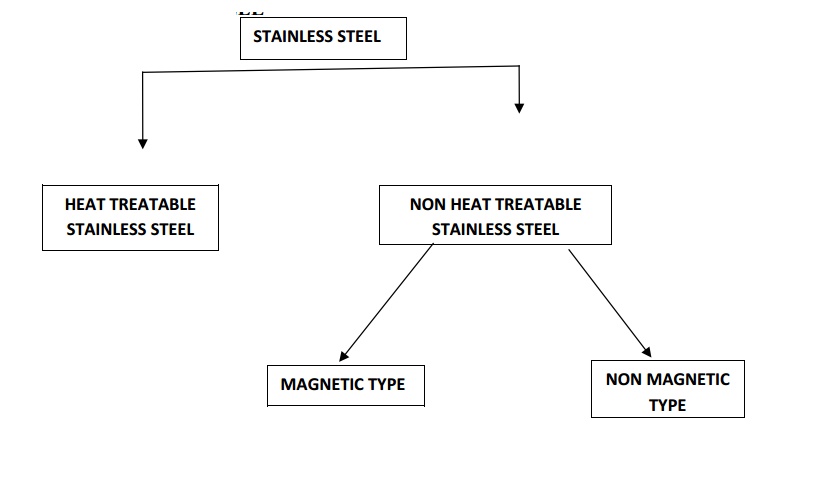

TYPES OF STAINLESS STEEL

1. HEAT TREATABLE STAINLESS STEEL

COMPOSITION Carbon-1.2%

Chromium-less

than 12-16%

PROPERTIES

Magnetic,tough & can be worked in cold

condition

USES

1. Can be used up to 800⁰C

2. Good resistant towards weather & water

3. In making surgical

instruments,scissors,blades,etc.

2.HEAT

TREATABLE STAINLESS STEEL

PROPERTIES

· Possess less strength at high temperature

· Resistant to corrosion

TYPES OF NON HEAT TREATABLE STAINLESS STEEL

(a)MAGNETIC TYPE

COMPOSITION

Chromium-12-22%

Carbon-0.35%

PROPERTIES

1. Can be forged,rolled & machined

2. Resist corrosion

USES

Used in making chemical equipments&

automobile parts.

(b)NON MAGNETIC TYPE

COMPOSITION

Chromium-18-26%

Nickel-8-21%

Carbon-0.15%

Total % of Cr & Ni is more than 23%.

EXAMPLE:18/8 STAINLESS STEEL COMPOSITION: Chromium-18%

Nickel-8%

PROPERTIES

1. Resistance to corrosion.

2. Corrosion resistance is increased by adding

molybdenum

USES

In making household utensils,sinks,dental &

surgical instruments.

NON FERROUS ALLOYS

· Do not contain iron as one of the main

constituent.

· Main constituents are

copper,aluminium,lead,tin,etc.

PROPERTIES

1. Softness & good formability

2. Attractive (or) very good colours

3. Good electrical & magnetic properties

4. Low density & coefficient of friction

5. Corrosion resistance

IMPORTANT NON FERROUS ALLOYS 1. COPPER ALLOYS

(BRASS)

Brass contains mainly copper & zinc

PROPERTIES

· Greater strength, durability &

machinability

· Lower melting points than Cu & Zn

· Good corrosion resistance & water

resistance property

2.BRONZE(COPPER

ALLOY)

Bronze contains copper & tin

PROPERTIES

· Lower melting point

· Better heat & electrical conducting

property

· Non-oxidizing,corrosion resistance & water

resistance property.

3.SOLDERS

Solders are low- melting alloys of tin &

lead

PROPERTIES

Solder is melted to join metallic surfaces ,especially

in the fields of electronic &

plumbing

USES

1. Used in electrical industry

2. Alloy with 50% tin is general-purpose solder

3. For sealing automotive radiator cores.

4. As fuses for fire-extinguishing

equipments,boiler plugs,etc.

Heat treatment of alloys (steel)

Heat treatment is defined as”

the process of heating and cooling of solid steel article under carefully

controlled condition”. During heat treatment certain physical properties are

altered without altering its chemical composition

Objectives (or) purpose of heat treatment

Heat treatment causes

i.

Improvement

in magnetic and electrical properties

ii.

Refinement

of grain structure

iii.

Removal

of the imprisoned trapped gases

iv.

Removal

of internal stress

v.

Improves

fatique and corrosion resistance

Types of heat treatment of alloys (steel) 1.

Annealing

Annealing means softening.

This is done by heating the metal to high temperature followed by slow cooling

in a furnace.

Purpose

of annealing

i.

It

increases the machinability

ii.

It also

removes the imprisoned gases

Types of

annealing

Annealing can be done in two types

i.

Low

temperature annealing (or) process annealing

ii.

High

temperature annealing 9or) full annealing

Low

temperature annealing (or)process annealing

It involves in heating steel

to a temperature below the lower critical point followed by slow cooling

Purpose

1. It improves mashinability by reliving the

internal stress or internal strain

2. It increases ductility and shock resistance

3. It reduce hardness

(i)

High temperature annealing (or) fault annealing

It

involves in heating to a temperature about 30 to 50⁰C above the higher critical temperature and

holding it at that temperature for sufficient time to allow the internal

changes to take place and then cooled room

temperature

The approximate annealing temperature of various

grades of carbon steel

are

1. Mild steel=840-870⁰c

2. Medium carbon steel=780-840⁰c

3. High carbon steel=760-780⁰c

Purpose

1. It increases the ductility and machinability

2. It makes the steel softer, together with an

appreciable increases in its toughness

2.Hardening

(or) quenching

· It is the process of heating steel beyond the

critical temperature and then suddenly cooling it either in oil or brine water

or some other fluid.

· The faster the rate of cooling harder will be

the steel produced.

· Medium and high carbon steel can be hardened

but low carbon steel cannot hardened

Purpose

1. It increases its resistance to wear ability ,to

cut other metal and strength .

2. It increases abrasion resistance.

3. Used for making cutting tools.

3.

TEMPERING

· It is the process of heating the already

hardened steel to a temperature lower than its own hardening temperature &

then cooling it slowly.

· The reheating controls the development of the

final properties

· Thus,

(a)For retaining strength

& hardness, reheating temperature should not exceed 400⁰C.

(b) For developing better

ductility & toughness, reheating temperature should be within 400-600⁰C.

Purpose

1. It removes stress &strains that might have

developed during quenching.

2. Increased toughness & ductility.

3. Used for cutting tools like blade,cutters etc.

4. NORMALISING

It is the purpose of heating steel to a

definite temperature (above its higher

critical temperature) & allowing it to cool gradually in air. Purpose

1. Recovers homogeneity

2. Refines grains.

3. Removes internal stresses

4. Increases toughness

5. Used in engineering works

NOTE: The difference between normalised &

annealed steel are

1. A normaled steel will not be as soft as

annealed steel.

2. Also normalizing takes much lesser time than

annealing.

5.CARBURIZING

· The mild

steel article is taken in a cast iron box within containing small pieces of

charcoal(carbon material).

· It is

heated to about 900 to 950⁰C & allow it for sufficient time,so that

the carbon is absorbed to required depth .

· The

article is then allowed to cool slowly within the box itself.

· The

outer skin of the article is converted into high carbon steel containing

about 0.8 to 1.2% carbon. Purpose

To produce hard surface on steel article

6.NITRIDING

· Nitriding

is the process of heating the metal alloy in presence of ammonia to about 550⁰C.

· The

nitrogen (obtained by the dissociation of ammonia) combines with the surface of

the alloy to form hard nitride.

Purpose

To get super-hard surface.

Related Topics