Chapter: Mechanical and Electrical : Power Plant Engineering : Diesel,Gas Tubine and Combined Cycle Power Plants

Operation Theory of Gas Turbine Power Plant

GAS TURBINE POWER PLANT

A gas

turbine, also called a combustion turbine, is a type of internal combustion

engine. It has an upstream rotating compressor coupled to a downstream

turbine,and a combustion chamber in-between. Energy is added to the gas stream

in the combustor, where fuel is mixed with air and ignited. In the high

pressure environment of the combustor, combustion of the fuel increases the

temperature. The products of the combustion are forced into the turbine

section.

There,

the high velocity and volume of the gas flow is directed through a nozzle over

the turbine's blades, spinning the turbine which powers the compressor and, for

some turbines, drives their mechanical output. The energy given up to the

turbine comes from the reduction in the temperature and pressure of the exhaust

gas.

Theory of

operation

Gasses passing through an ideal a gas turbine

undergo three thermodynamic processes. These are isentropic compression,

isobaric (constant pressure) combustion and isentropic expansion. Together

these make up the Brayton cycle.

In a practical gas turbine,

gasses are first accelerated in either a centrifugal or radial compressor.

These gasses are then slowed using a diverging nozzle known as a diffuser,

these process increase the pressure and temperature of the flow. In an ideal

system this is isentropic. However, in practice energy is lost to heat, due to

friction and turbulence. Gasses then pass from the diffuser to a combustion

chamber, or similar device, where heat is added. In an ideal system this occurs

at constant pressure (isobaric heat addition). As there is no change in

pressure the specific volume of the gasses increases.

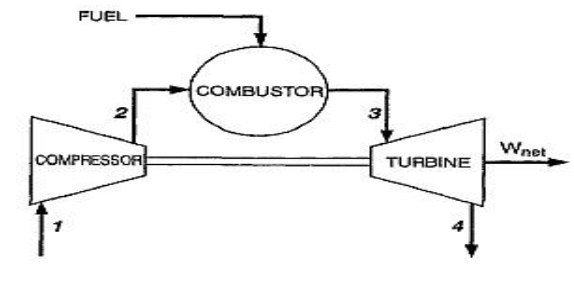

LAYOUT OF GAS TURBINE POWER PLANT

The gas

turbine power plants which are used in electric power industry are classified

into

two groups as per the cycle of operation.

(1) Open

cycle gas turbine.

(2) Closed

cycle gas turbine.

Open cycle gas turbine 1-

Atmospheric Air

2-

Compressed Atmospheric Air

3- Fuel

air mixture after compression

4- Exhaust gases.

The

heated gases coming out of combustion chamber are then passed to the turbine

where

it expands doing mechanical work. Part of the power developed

by the turbine is utilized in

driving the compressor and other accessories and remaining is

used for power generation.

Since ambient air enters into the compressor and gases coming

out of turbine are exhausted into the atmosphere, the working medium must be

replaced continuously. This type of cycle is known as open cycle gas turbine

plant and is mainly used in majority of gas turbine power plants as it has many

inherent advantages.

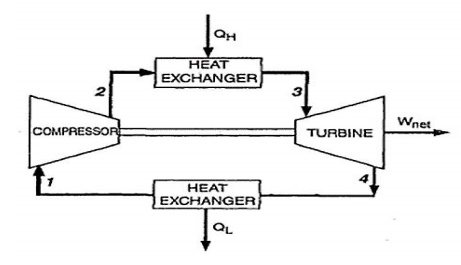

Closed

cycle gas turbine power plant

In this, the compressed air from

the compressor is heated in a heat exchanger (air heater) by some external

source of heat (coal or oil) at constant pressure. Then the high pressure hot

gases expand passing through the turbine and mechanical power is developed. The

exhaust gas is then cooled to its original temperature in a cooler before

passing into the compressor again.

The main difference between the

open and closed cycles is that the working fluid is continuously replaced in

open cycle whereas it is used again and again in a closed cycle. The open cycle

plant is much lighter than the closed cycle. Hence it is widely used.

1- Low Pressure Working Fluid @ Low temperature

2- High Pressure Working Fluid

3- Fuel + Working Fluid mixture @ High Pressure

and Temperature 4- Low Pressure Working Fluid @ Temperature T4 <

Temperature T3

In closed cycle gas turbine

plant, the working fluid (air or any other suitable gas) coming out from

compressor is heated in a heater by an external source at constant pressure.

The high temperature and

high-pressure air coming out from the external heater is passed through the gas

turbine. The fluid coming out from the turbine is cooled to its original

temperature in the cooler using external cooling source before passing to the

compressor.The working fluid is continuously used in the system without its

change of phase and the required heat is given to the working fluid in the heat

exchanger

Related Topics