Chapter: Mechanical and Electrical : Power Plant Engineering : Diesel,Gas Tubine and Combined Cycle Power Plants

Kaplan turbine

Kaplan

turbine

Working

principle

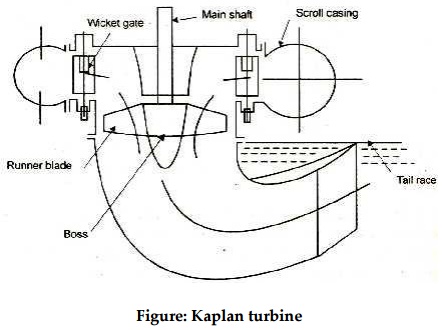

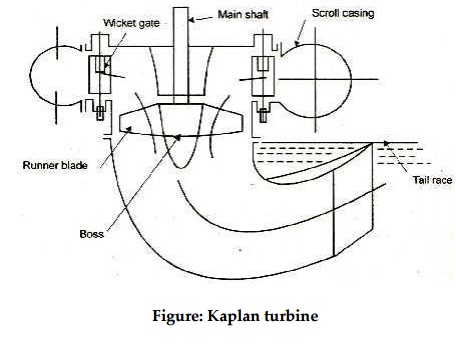

Figure: Kaplan turbine

The water from the scroll casing flows over the guide

vanes. It is deflected through 90° between guide vanes and runner.

Then, it flows axially into the runner. The blades are shaped such that water

flows axially in the runner. The force exerted on the blades causes the runner

shaft to rotate. This rotation is transmitted to the generator which is couple

to the runner shaft. After passing through the runner, the water enters the

tailrace through a draft tube.

Governing

of Kaplan turbine

A Kaplan turbine has adjustments in both guide vanes and

runner vanes. Generally, double regulators are provided in a Kaplan turbine.

The governor regulates the guide blade opening as well as the runner vane

angles simultaneously. The adjustment of guide vanes is similar to that of a

Francis turbine. The runner vanes are regulated by a separate Servomotor. The

control valves for both the runner and guide vanes are interconnected to ensure

a define runner vane angle for the given vane opening.

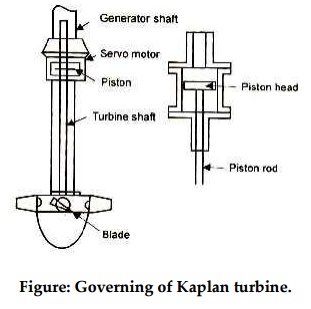

Figure: Governing of Kaplan turbine.

The runner vane angles may be adjusted while the turbine

is in motion. The piston rod of the servomotor (of the runner vanes) pass

through the hollow turbine shaft as shown in figure. The movement of the piston

is transmitted to the runner of the piston is transmitted to the runner vane by

a small crank connected to cross head. The servomotor acts as the coupling

between the turbines shaft and the generator shaft. Oil from the governor is

admitted to the upper or lower side of the servomotor piston through pipes.

This will reduce or increase the blade angle. The governor actuates

simultaneously both the guide vane and the runner vane. Thus for all loads, the

turbine is able to maintain high efficiency.

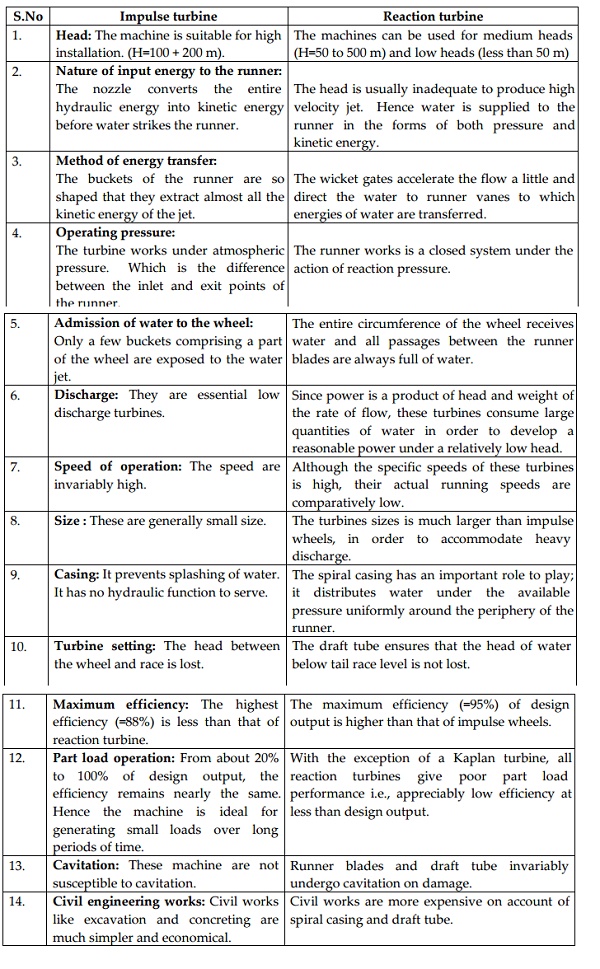

Compare Impulse and reaction turbines

S.No Impulse turbine

1. Head:

The machine is suitable for high installation. (H=100 +

200 m).

2. Nature of input energy to the runner:

The nozzle converts

the entire hydraulic energy

into kinetic energy before water

strikes the runner.

3. Method of energy transfer:

The buckets of

the runner are

so shaped that they extract

almost all the kinetic energy of the

jet.

4. Operating pressure:

The turbine works

under atmospheric pressure. Which

is the difference

between the inlet and exit points of the runner.

5. Admission of water to the wheel:

Only a few buckets

comprising a part of the wheel are

exposed to the water jet.

6. Discharge:

They are essential

low discharge turbines.

7. Speed of operation:

The speed are

invariably high.

8. Size : These are generally small size.

9. Casing: It prevents splashing of water. It has no hydraulic function to serve.

10. Turbine

setting: The head

between the wheel and race is lost.

11. Maximum

efficiency: The highest

efficiency (=88%) is less than that of

reaction turbine.

12. Part load operation: From about 20% to

100% of design

output, the efficiency

remains nearly the

same. Hence the

machine is ideal

for generating small

loads over long

periods of time.

13. Cavitation:

These machine are

not susceptible to cavitation.

14. Civil engineering works: Civil works like

excavation and concreting

are much simpler and economical.

S.No Reaction turbine

1. Reaction turbine The machines can be used for medium

heads (H=50 to 500 m) and low heads (less than 50 m)

2. The head is usually inadequate to produce high velocity

jet. Hence water

is supplied to the

runner in the forms of

both pressure and kinetic energy.

3. The wicket gates accelerate the flow a little and

direct the water

to runner vanes

to which energies of water are

transferred.

4. The runner works is a closed system under the action of

reaction pressure.

5. The entire circumference of the wheel receives

water and all

passages between the

runner blades are always full of water.

6. Since power is a product of head and weight of the rate

of flow, these turbines consume large quantities of

water in order

to develop a

reasonable power under a relatively low head.

7. Although the specific speeds of these turbines is high,

their actual running

speeds are comparatively low.

8. The turbines sizes is much larger than impulse

wheels, in order

to accommodate heavy discharge.

9. The spiral casing has an important role to play;

it distributes water

under the available pressure uniformly around the

periphery of the runner.

10. The draft tube ensures that the head of water below

tail race level is not lost.

11. The

maximum efficiency (=95%)

of design output is higher than

that of impulse wheels.

12. With the exception

of a Kaplan

turbine, all reaction turbines

give poor part

load performance i.e., appreciably low efficiency at less than design

output.

13. Runner

blades and draft

tube invariably undergo cavitation

on damage.

14. Civil works are more expensive on account of spiral

casing and draft tube.

Related Topics