Chapter: Mechanical : Finite Element Analysis : One Dimensional Finite Element Analysis

One Dimensional Finite Element Analysis

ONE DIMENSIONAL FINITE ELEMENT ANALYSIS

ONE

DIMENSIONAL ELEMENTS

Bar and beam elements are considered as One

Dimensional elements. These elements are often used to model trusses and frame

structures.

Ø Bar, Beam and Truss

Bar is a member which resists only axial loads. A

beam can resist axial, lateral and twisting loads. A truss is an assemblage of

bars with pin joints and a frame is an assemblage of beam elements.

Ø Stress, Strain and Displacement

Stress is denoted in the form of vector by the

variablexasσx, Strain

is denoted in the form of vector by the variable x as ex,

Displacement is denoted in the form of vector by the variable x as ux.

Ø Types of

Loading

(1) Body force (f)

It is a distributed force acting on every

elemental volume of the body. Unit is Force / Unit volume. Ex: Self weight due

to gravity.

(2)

Traction (T)

It is a distributed force acting on the surface of

the body. Unit is Force / Unit area. But for one dimensional problem, unit is

Force / Unit length. Ex: Frictional resistance, viscous drag and Surface shear.

(3) Point

load (P)

It is a

force acting at a particular point which causes displacement.

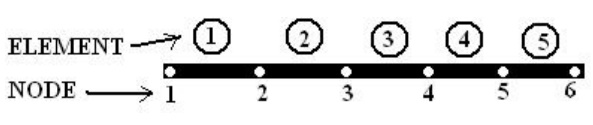

Ø Finite Element Modeling

It has

two processes.

(1) Discretization

of structure

(2) Numbering

of nodes.

Ø CO –

ORDINATES

(A) Global co –ordinates,

(B) Local co –ordinates and

(C) Natural co –ordinates.

Ø Natural

Co – Ordinate (ε)

Integration

of polynomial terms in natural co –ordinates

for two dimensional elements can be performed by using the formula,

Shape function

N1N2N3 are usually denoted as shape function. In one

dimensional

problem,

the displacement

u = SNi ui =N1 u1

For two

noded bar element, the displacement at any point within the

element

is given by,

u = SNi ui =N1 u1 + N2

u2

For three

noded triangular element,

the displacement at any point

within

the element is given by,

u = SNi ui =N1 u1 + N2

u2 + N3 u3

v = SNi vi =N1 v1 + N2

v2 + N3 v3

Shape

function need to satisfy the following

(a) First

derivatives should be finite within an element; (b) Displacement should

be

continuous across the element boundary

Polynomial Shape function

Polynomials

are used as shape function due to the following reasons, (1)

Differentiation

and integration of polynomials are quite easy.

(2) It is

easy to formulate and computerize the finite element equations.

(3) The

accuracy of the results can be improved by increasing the order of

Ø Properties

of Stiffness Matrix

1. It is a

symmetric matrix,

2. The sum

of elements in any column must be equal to zero,

3. It is an

unstable element. So the determinant is equal to zero.

Ø Problem

(I set)

1.A two

noded truss element is shown in figure. The nodal displacements are u1

= 5 mm and u2 = 8 mm. Calculate the displacement at x = ¼ , 1/3 and

½ .

Ø Problem

(II set)

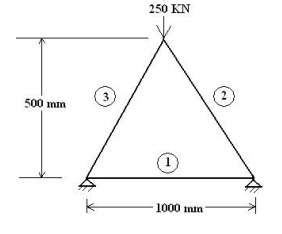

1. Consider

a three bar truss as shown in figure. It is given that E = 2 x 105

N/mm2. Calculate

(a) Nodal displacement,

(b) Stress in

each member and

(c) Reactions

at the support. Take Area of element 1 = 2000 mm2, Area of element 2

= 2500 mm2, Area of element 3 = 2500 mm2.

Ø Types of

beam

1. Cantilever

beam,

2. Simply

Supported beam,

3. Over

hanging beam,

4. Fixed

beam and

5. Continuous

beam.

Ø Types of

Transverse Load

1. Point or

Concentrated Load,

2. Uniformly

Distributed Load and

3. Uniformly

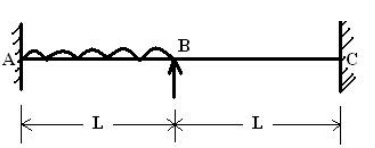

Ø Problem

(III set)

1. A fixed beam of length 2L m carries a uniformly distributed

load of w (N/m)

which

runs over a lengt h of L m from the fixed end. Calculate the rota tion at Point

B.

LINEAR

STATIC ANALYSIS( BAR ELEMENT)

Most structural analysis pro

blems can be treated as linear static problems, b ased on the following

assumptions

1.Small

deformations (loading pattern is not changed due to the defor med shape)

2.Elastic

materials (no plasticity or failures)

3.Static

loads (the load is applied to the structure in a slow or steady fashion)

Linear analysis can pro vide most of the information

about the behavior of a structure, and can be a good ap proximation for many

analyses. It is also the ba ses of nonlinear analysis in most of th e cases.

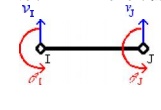

BEAM ELEMENT

A beam element is defin ed as a

long, slender member (one dimension i s much larger than the other two) that is

subje cted to vertical loads and moments, which pro duce vertical displacements

and rotations. T he degrees of freedom for a beam element are a vertical

displacement and a rotation at e ach node, as opposed to only an horizontal di

splacement at each node for a truss element.

Degrees of Freedom

Degrees of freedom are defined as

the number of independent coordina tes necessary to specify the configuration

of a system. The degrees of freedom for a general situation consists of three

translations in t he x, y, and z directions and three rotations

abou t the x, y, and z axes. A one-dimensional beam element has

four degrees of freedom, which include, a vertical displacement and a

rot ation at each node.

Assumptions

Nodal Forces and Moments

Forces and moments can only be

applied at the nodes of the beam element, not between the nodes. The nodal

forces and moments, fc, are related to the nodal displacements and rotations, ![]()

![]() through the ele ment stiffness

matrix,Kv.

through the ele ment stiffness

matrix,Kv.

Constant Load

The loads that are appli ed to

the beam element are assumed to be stat ic and not to vary over the time period

being considered, this assumption is only valid if the r ate of change of the

force is much less than th e applied force (F >> dF/dt). If

the loads vary significantly, (if the variation in load is not much less than

the applied force) then the pro blem must be considered as dynamic.

Weightless Member

The weight (W) of the beam is

neglected, if it is much less than the total resultant forces (F) acting on the

beam. If the weight of the beam is not neglected, then its effects must be

represented as vertical forces acting at the nodes, by dividing up the weight

and lumping it at the nodes, proportionally according to it's placement along

the beam.

Prismatic Member

The beam element is assumed to

have a constant cross-section, which m eans that the cross-sectional area and

the mom ent of inertia will both be constant (i.e., the be am element is a

prismatic member). If a bea m is stepped, then it must be divided up into

sections of constant cross-section, in order to obtain an exact solution. If a

beam is tape red, then the beam can be approximated by us ing many small beam

elements, each having the same cross-section as the middle of the tap ered

length it is approximating. The more sections that are used to approximate a

tapered be am, the more accurate the solution will be.

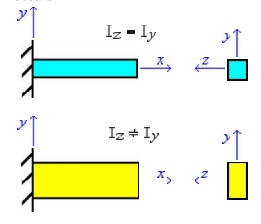

The moment of inertia is a geometric

property of a beam element, which describes the beams resistance to bending and

is assumed to be constant through the length of the element. The moment of

inertia can be different along different axes if the beam el ement is not

symmetric, we use the moment of inertia (I) of the axis about which the bendin

g of the beam occurs

Where (Iz)

refers to the moment of inertia, resisting bending about the "z"

axis and (Iy) about the "y" axis.

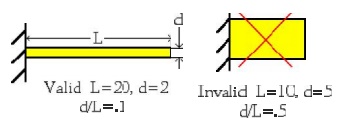

The Beam Element is a Slende r Member

A beam is assumed to be a slender

member, when it's length (L) is moree than 5 times as long as either of it's

cross-sec tional dimensions (d) resulting in (d/L<.2). A beam must be

slender, in order for the beam equations to apply, that were used to derive our

FEM equations.

The Beam Bends without Twisting.

It is assumed that the c

ross-section of the beam is symmetric about the plane of bending (x-y

plane in this case) and will undergo symmetric bending (where n o twisting of

the beam occurs during the bend ing process). If the beam is not symmetric abo

ut this plane, then the beam will twist during bending and the situation will

no longer be on e-dimensional and must be approached as an u nsymmetric bending

problem (where the beam twists while bending) in order to obtain a cor rect

solution.

Cross Section Remains Plane

When a beam element b ends, it is

assumed that it will deflect uniformly, thus the cross section will move

uniform ly and remain plane to the beam centerline. In other words, plane

sections remain plane and normal to the x axis before and after bending.

Axially Rigid

The one-dimensional bea m element

is assumed to be axially rigid, mean ing that there will be no axial displacement

( u) along the beams centriodal axis. This implies that forces will only

be applied perpendicular to the beams centriodal axis. The one-dimensional beam

element can be used only when the degrees of freedom are limited to vertical

displacements (perpendicular to the beams centriodal axis) and rotations in one

plane. If axial displacements are present then a one-dimen sional bar element

must be superimposed w ith the one-dimensional beam element in ordder to obtain

a valid solution.

Homogenous Material

A beam element has the s ame

material composition throughout and there fore the same mechanical properties

at every position in the material. Therefore, the modulus of elasticity E is

constant throughout the beam element. A member in which the material properties

varies from one point to the next in t he member is called inhomogenous

(non-homo genous). If a beam is composed of different ty pes of materials, then

it must be divide up into elements that are each of a single homogeneous

material, otherwise the solution will not be exact.

Isotropic Material

A beam element has the same

mechanical and physical properties in all directions, i.e., they are

independent of dir ection. For instance, cutting out three tensile test

specimens, one in the x-direction, one in t he y-direction and

the other oriented 45 degre es in the x-y plane, a tension test

on each s pecimen, will result in the same value for th e modulus of elasticity

(E), yield strength and ultimate

strength. Most metals arre considered isotropic. In contrast fibrous m

aterials, such as wood, typically have properties that are directionaly

dependant and are generally considered anisotropic (not isotropic).

The Proportional Limit is not Exceeded

It is assumed that the b eam

element is initially straight and unstressed. It is also assumed that the

material does n ot yield, therefore the beam will be straight af ter the load

is released. These assumptions me an that the beam must be made of an elastic

material, one which will return to it's original size and shape when all loads

are removed, if not stressed past the materials elastic or proportional limit.

It is also assumed that the beam is not stressed past the proportional limit,

at w hich point the beam will take a permanent set and will not fully return to

it's original size an d shape, when all loads are removed. Below th e

proportional limit an elastic material is in the linear elastic range, where

the strain varies linearly with the

applied load and the stress ( ) varies

linearly according to: σ = Eε , where E is the modulus

of elasticity.

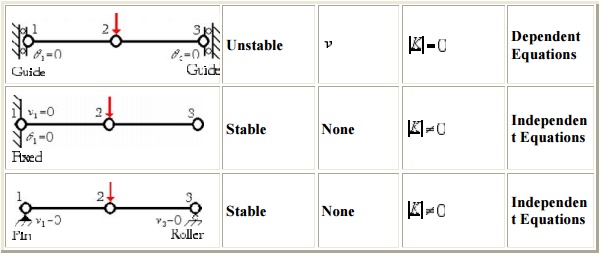

Rigid Body Modes for the

One-Dimensional Beam Element

Rigid Body Modes for the

One-Dimensional Beam Element

Rigid body motion occurs when

forces and/or moments are applied to an unrestrained mesh (body), resulting in

motion that occurs without any deformations in th e entire mesh (body). Since

no strains (deformations) occur during rigid body motion, there can be no

stresses developed in the mesh. In order to obtain a unique FEM solution, rigid

body motion must be constrained. If rigid body motion is not constrained, then

a singular system of equations will result, since the determinate of the mesh

stiffness matrix is equal to zero (i.e., ( |K| - 0)

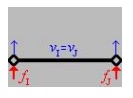

There are two rigid body modes for

the one-dimensional beam element , a translation (displacement) only and a

rotation only. These two rigid body modes can occu r at the same time resulting

in a displacement and a rotation simultaneously. In order to e liminate rigid

body motion in a 1-D beam elem ent (body), one must prescribe at least two no

dal degrees of freedom (DOF), either two displacements or a

displacement and a rotation. A DOF can be equal to zero or a non-zero know n

value, as long as the element is restrained fro m rigid body motion

(deformation can take pl ace when forces and moments are applied) .

For simplicity we will in troduce

the rigid body modes using a mesh c omposed of a single element. If only translatio

nal rigid body motion occurs, then the displaceement at local node I

will be equal to the displacement at local node J. Since the displacem

ents are equal there is no strain developed in t he element and the applied

nodal forces cause the element to move in a rigid (non-deflected) vertical

motion (which can be either up as show n below or it can be in the downward

directio n depending on the direction of the applied force s).

This

rigid body mode can be suppressed by prescribing a vertical nodal displace

ment.

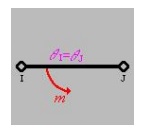

If rotational rigid body motion

occurs, then the rotation at local node I will be equal to the rotation

at local node J (i.e., in magnitude and direction). In this situation th

e nodal forces and/or moments applied to the element, cause the element to

rotate as a rigid body (either clockwise as shown below or counterclockwise

depending on the direction o f the applied forces and/or moments).

This

rigid body mode can be suppressed by prescribing a nodal translation or

rotation.

If translational and

rotational rigid body motion occurs simultaneously then:

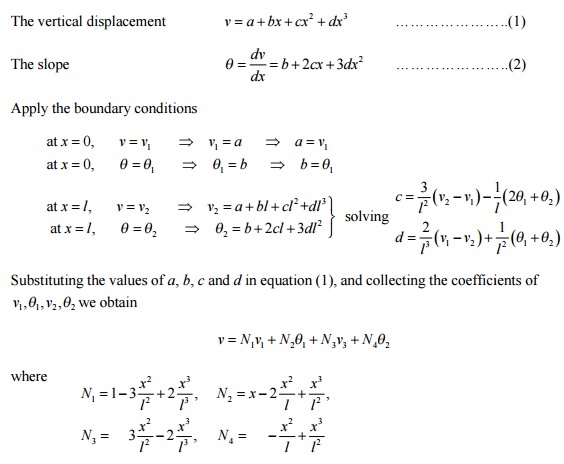

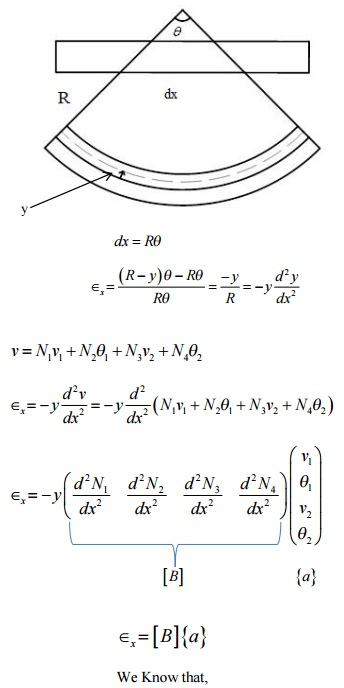

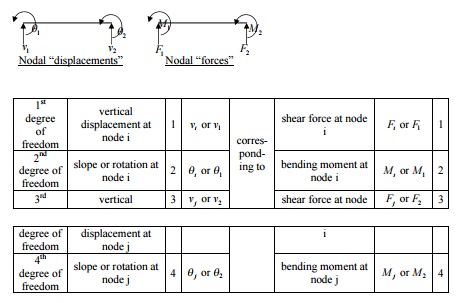

1-D 2-NODED CUBIC BE AM ELEMENT MATRICES

A single 1-d 2-noded c ubic beam

element has two nodes, with two degrees of freedom at each node (one vertic al

displacement and one rotation or slope). The re is a total of 4 dof and the

displacement polynomial function assumed should have 4 terms, so we choose a

cubic polynomial for the vertical deflection. Slope is a derivative of the

vertical deflections.

DEVELOPMENT OF ELEMENT EQUATION

BEAM ELEMENT

A beam is a long, slender structural member

generally subjected to transverse loading that produces significant bending

effects as opposed to twisting or axial effects. An elemental length of a long

beam subjected to arbitrary loading is considered for analysis. For this

elemental beam length L, we assign two points of interest, i.e., the ends of

the beam, which become the nodes of the beam element. The bending deformation

is measured as a transverse (vertical) displacement and a rotation (slope).

Hence, for each node, we have a vertical displacement and a rotation (slope) – two

degrees of freedom at each node. For a single 2-noded beam element,

we have a total of 4 degrees of freedom. The associated “forces” are shear

force and bending moment at each node.

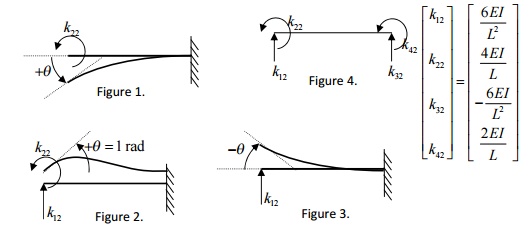

The stiffness term kij

indicates the force (or moment) required at i to produce a unit deflection (or

rotation) at j, while all other degrees of freedom are kept zero.

Sign

conventions followed

Upward

forces are positive and upward displacements are positive.

Counter-clockwise

moments are positive and counter-clockwise rotations are positive.

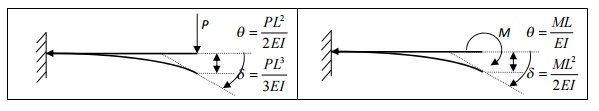

Formulae required –

cantilever beam subjected to concentrated load and moment.

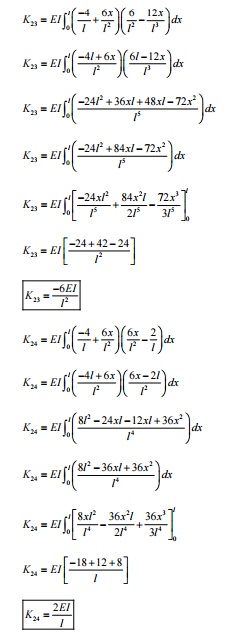

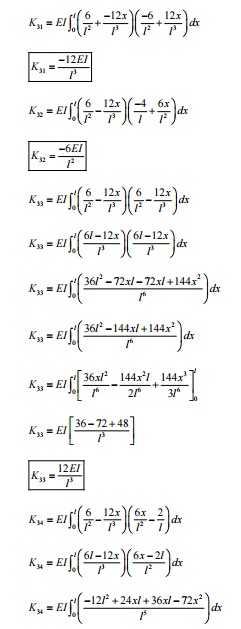

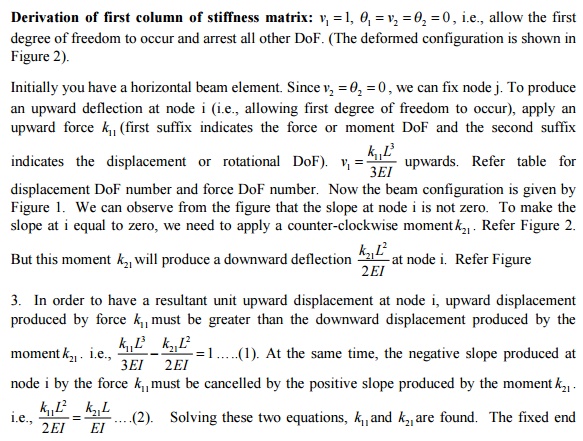

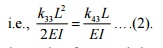

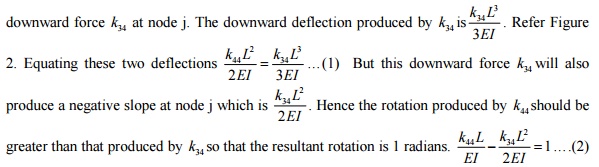

1 ELEMENT MATRICES AND VECTORS

reaction force and the reaction

moment are assumed to be acting upwards and counterclockwise, respectively. Now

use force equilibrium equation to find fixed end reaction force k ….…

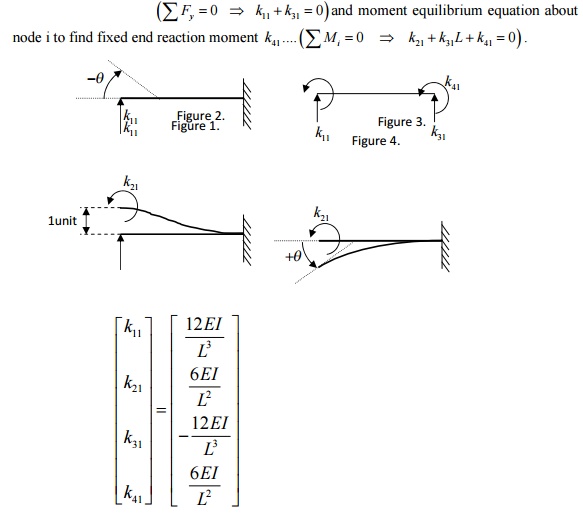

Derivation of second column of

stiffness matrix:

found. The fixed end reaction

force and the reaction moment are assumed to be acting upwards and

counterclockwise, respectively. Now use force equilibrium equation to find

fixed end reaction force

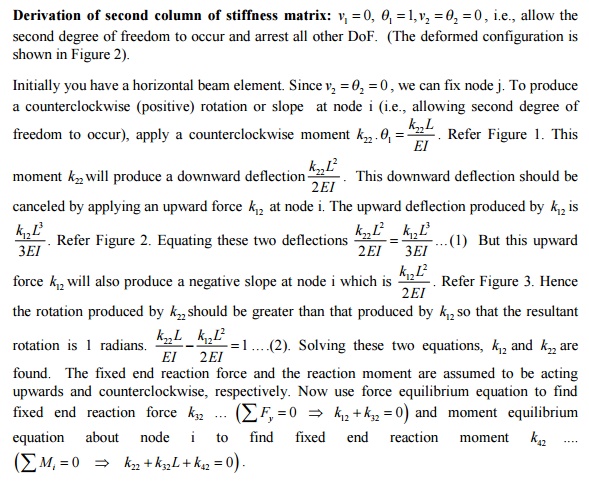

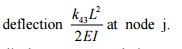

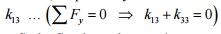

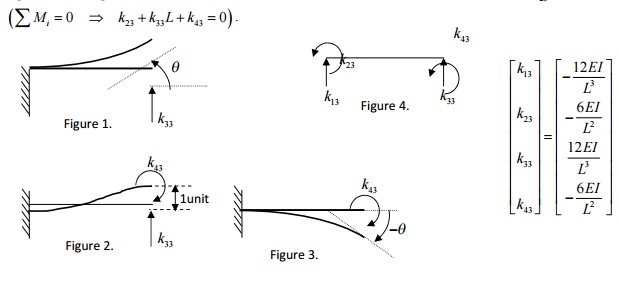

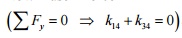

Derivation of third column of

stiffness matrix:

Derivation of third column of

stiffness matrix: v1 = 0, q1

=0,

v2 1,= q 2 0 , i.e., allow the third degree of

freedom to occur and arrest all other DoF. (The deformed configuration is shown

in Figure 2).

Initially you

have a horizontal beam element. Since V1=q1=0 we can fix node i. To produce an upward deflection

at node j (i.e., allowing third degree of freedom to occur), apply an upward

force k33 .

upwards. Now the beam configuration is given by

Figure 1. We can observe from 3EI

![]()

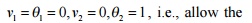

the figure that the slope at node

j is not zero. To make the slope at j equal to zero, we need to apply a

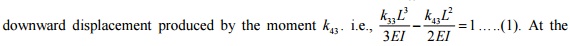

clockwise moment k43 . Refer Figure 2. But this moment k43

will produce a downward

at node j. Refer Figure 3. In

order to have a resultant unit upward 2EI displacement at node j, upward

displacement produced by force k33 must be greater than the

same time, the positive slope

produced at node j by the force k33 must be cancelled by the negative slope

produced by the moment k43

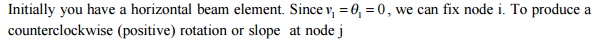

Solving these two equations, k33

and k43 are found. The fixed end reaction force and the reaction moment are

assumed to be acting upwards and counterclockwise, respectively. Now use force

equilibrium equation to find fixed end reaction force  and moment equilibrium equation

about node i to find fixed end reaction moment k23

....

and moment equilibrium equation

about node i to find fixed end reaction moment k23

....

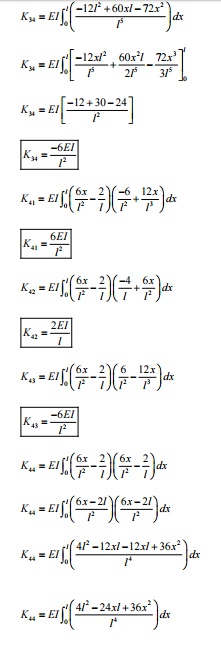

Derivation of fourth column of

stiffness matrix:

fourth degree of

freedom to occur and arrest all other DoF. shown in Figure 2).

fourth degree of

freedom to occur and arrest all other DoF. shown in Figure 2).

i.e., allow the (The deformed configuration is shown in fig.

Initially you have a horizontal beam element.

Since  , we can fix node i.

To produce a counterclockwise (positive) rotation or slope at node j (i.e., allowing fourth degree of

freedom to occur), apply a

counterclockwise moment k44 . Refer Figure 1. This moment k44 will produce

a upward deflection

, we can fix node i.

To produce a counterclockwise (positive) rotation or slope at node j (i.e., allowing fourth degree of

freedom to occur), apply a

counterclockwise moment k44 . Refer Figure 1. This moment k44 will produce

a upward deflection ![]() This upward deflection should be canceled by applying

a

This upward deflection should be canceled by applying

a

Refer Figure 3. Solving these two

equations, k34 and k44 are found. The fixed end reaction force and the reaction

moment are assumed to be acting upwards and counterclockwise, respectively.

Now use force

equilibrium equation to find

fixed end reaction

force k14  and moment equilibrium equation

about node i to find fixed end

and moment equilibrium equation

about node i to find fixed end

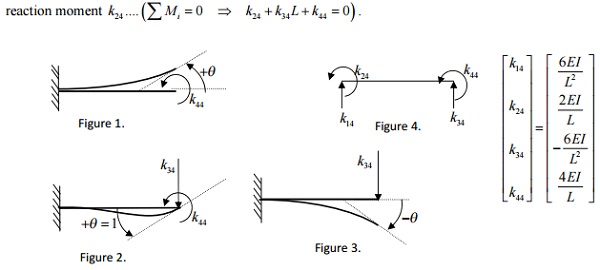

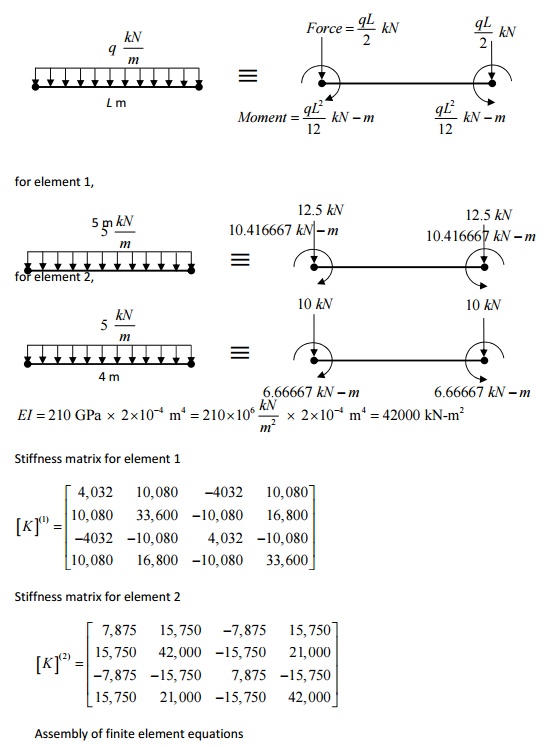

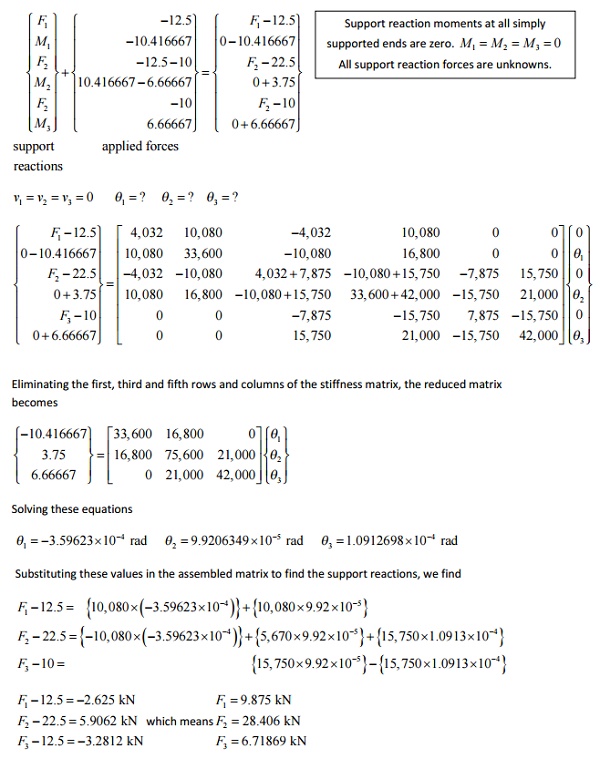

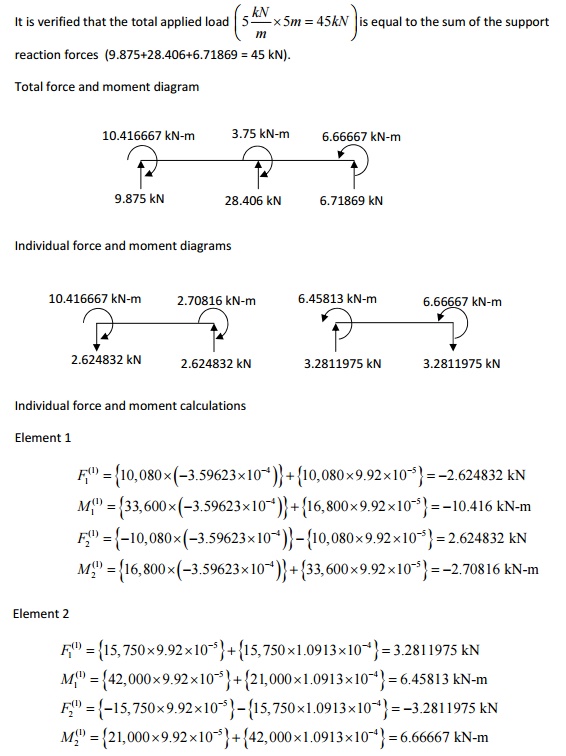

Problem

Find the slopes at the supports and support reac

beam shown in Figure-.4m4.

TakeDarylP4E=210-24LoganpageGPa,208I. = 2×10

Finite element representation of the problem

Conversion of UDL into nodal forces and nodal mo

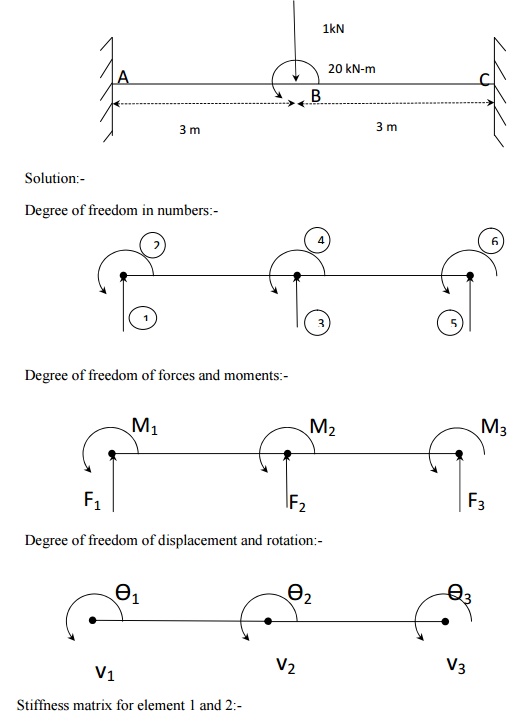

PROBLEM

Given that E=210 GPa and I=4×10 -4

m4, cross section of the beam is constant. Determine the deflection

and slope at point C. calculate the reaction forces and moments. DARYL LOGAN P

171-172

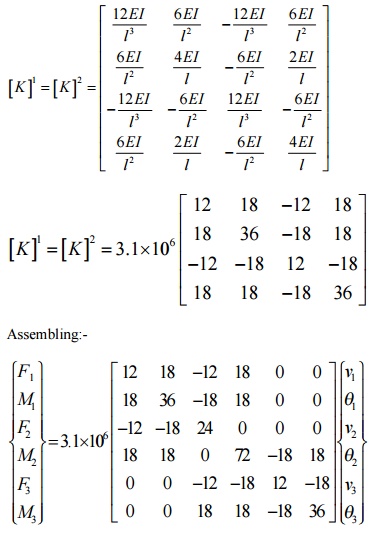

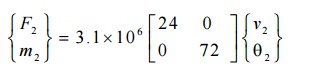

Boundary condition:-

F2=-10 kN; M2=20 kN-m

Therefore first, second, fifth, sixth columns are ineffective and hence

the reduced matrix is given by

Deflection and slope at point c:-

V2= -1.34×10 -4

m = -0.134 mm

Ѳ2= 8.96×10

-5

rad

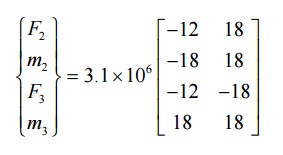

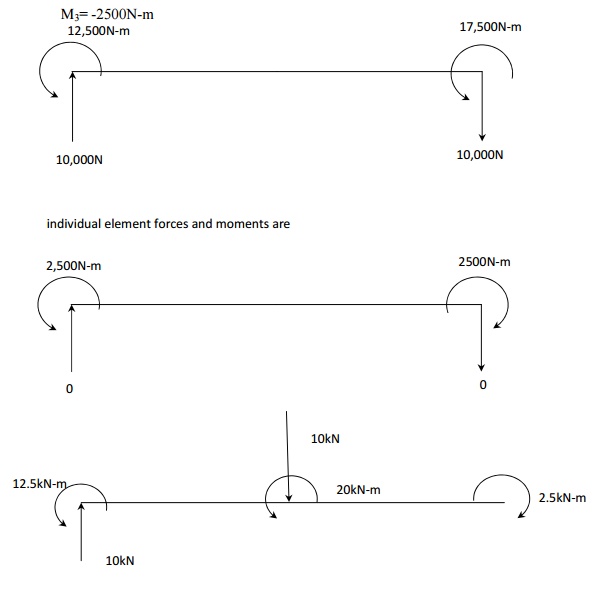

Reaction forces and moments:-

F1=10000N

M1=12500N-m

F3=0

M3=

-2500N-m

Related Topics