Chapter: Mechanical : Manufacturing Technology : Metal Casting Process

Non-destructive methods used for finding casting Defects

Non-destructive methods used for finding casting Defects.

The various casting defects may be on the surface, under the surface of the solidified casting. These defects are found out by the below mentioned non-Destructive Inspection methods.

1. Ultra Sonic Inspection

2. Liquid Penetrant Inspection

3. Magnetic Particle Inspection

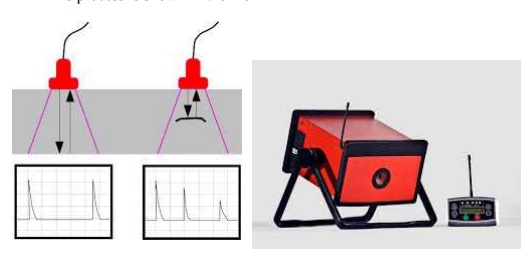

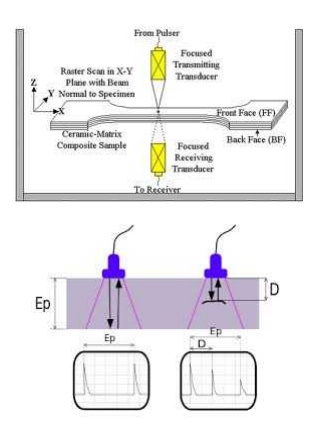

1.Ultra sonic Inspection.

Ultrasonic sound waves are in the frequency decibel which cannot be heared by a human ear. The bats use this kind of sound waves in-order to find the obstacles while flying. These waves will be reflected back to the source when obstructed. Similarly, in ultrasonic testing there is a probe which sends the ultrasonic sound waves into the metal part that is to be inspected. The sound waves will be reflected back after hitting the other end of the metal.

If there is a crack in the middle of the metal part, then the sound waves will be reflected before in advance.

This process is shown in the monitor as a graph. Thus the crack is identified and decided wheather to rectify the crack or reject the metal part.

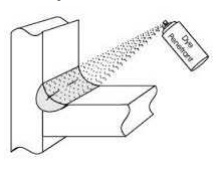

2. LPT (Liquid Penetrant Testing)

Chemicals Used.

1. Cleaner

2. Potassium Permanganate solution

3. Developer.

Initially the Casted Metal Part to be inspected is cleaned using Cleaner. Dust, oil, Grease etc are removed. Then potassium permanganate solution is sprayed over the surface of the metal part and allowed to remain for 5 – 7 mins. Then the potassium permanganate solution is cleaned.

Now developer is applied over the surface. Due to capillary action the rose/pink colour potassium permanganate liquid will reach the surface of the crack. And now the crack will be visible in pink/rose color.Thus the surface cracks are inspected on the casting.

ADVANTAGES & LIMITATIONS OF LPT

Cost of the chemicals is low when compared to UT & MPT.

Huge / Large size components can be inspected, only on the particular area, where it is required.

Time taken is less.

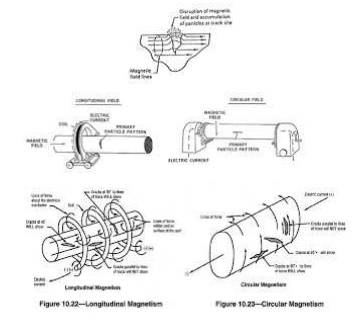

3.MPT Magnetic Particle testing.

This method of inspection is used on magnetic ferrous castings for detecting invisible

surface or slightly subsurface defects. Deeper subsurface defects are not satisfactorily detected because the influence of the distorted lines of magnetic flux (owing to a Discontinuity) on the magnetic particles spread over the casting.

The defects commonly revealed by magnetic particle inspection are quenching cracks, overlaps, thermal cracks, seams , laps, grinding cracks, fatigue cracks, hot tears Etc,

Working Principle.

When a piece of metal is place in a magnetic field and the lines of magnetic flux get intersected by a discontinuity such as a crack or slag inclusion in a casting, magnetic poles are induced on either side of the discontinuity. The discontinuity causes an abrupt change in the path of magnetic flux flowing through the casting normal to the discontinuity, resulting in a local flux leakage field and interference with the magnetic lines of force. This local flux disturbance can be detected by its effect upon magnetic particles which are attracted to the region of discontinuity and pile up and bridge over the discontinuity.

A surface crack is indicated (under favorable conditions) by a line of fine particles following the crack outline and a subsurface defect by a fuzzy collection of the magnetic particles on the surface near the discontinuity. Maximum sensitivity of indication is obtained when the discontinuity lies in a direction normal to the applied magnetic field and when the

Related Topics