Chapter: Mechanical : Manufacturing Technology : Manufacturing of Plastic Components

Manufacturing of Plastic Components

MANUFACTURING OF PLASTIC COMPONENTS

Plastics are the best

alternatives used in the areas where the component size is very small and

weight reduction is required in order to minimize the cost of material. Hence

knowledge about various types of plastics, its properties, production method

etc is very important.

TYPES OF PLASTICS

Plastics are of two types 1.Thermo plastics

2.Thermosetting Plastics

Common

plastics USED in molding are

• HDPE

(stiff bottle, toys, cases, drum)

• LDPE

(flexible bottle)

• PP

(higher temperature bottle)

• PVC

(clear bottle, oil resistant containers)

• PET (soda

pop bottle)

• Nylon

(automotive coolant bottle, power steering reservoir)

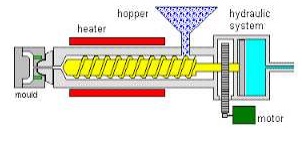

INJECTION

MOULDING

Injection

Molding

Most

widely used process. Suitable for high production of thermoplastics. Charge fed

from a hopper is heated in a barrel and forced under high pressure into a mold

cavity. Several types. Variety of parts can be made.

Basic

components:

mold pieces (define the geometry of the part), and sprue,

gates, runners, vents, ejection pins, cooling system

There are two types of injection moulding.

1. Plunger

type injection moulding.

2. Screw

type injection moulding.

In screw type injection moulding

machine the plunger is replaced by a screw.A receiprocating screw now forces

the material into the mould.since the screw action generally helps to pack the

materials better , a given plunger travel will push more material into the

cavity. Finally the action of the screw , as it rotates and mixes, adds energy

to the melt.

Band heaters are still needed to

fully heat the melt. All of this results in a much better and more consistent

part.

Virtually all industrial presses are screw type presses.

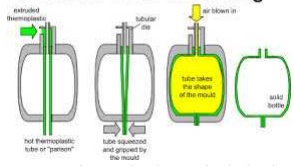

BLOW

MOULDING

used to make thermoplastic

bottles and hollow sections. Starting material is a round heated solid-bottom

hollow tube – perform.

Perform inserted into two die halves and air is

blown inside to complete the process

General steps

• Melting

the resin- done in extruder

• Form the

molten resin into a cylinder or tube (this tube is called parison)

• The

parison is placed inside a mold, and inflated so that the plastic is pushed

outward

against

the cavity wall

• The part

is allowed to cool in the mold and is then ejected

• The part

is trimmed

The

parison can be formed by

A)Extrusion

process

B)Injection

molding process

(A)Extrusion blow molding

– Parison is formed from by forcing

the plastic through an extrusion

die.

Material enters the die, flow around the mandrel

so that extrudate would be cylindrical

– The die would have a hole at the

center so that air could be blown into the

cylinder

– In some blow molding operations,

the air is introduced from the bottom through

an inlet

This process can be;

– continuous

extrusion blow molding

• During the

process, the extrusion

runs continuously, thus

making a

continuous

parison.

• using

multiple mold to match the mold cycle to the extrusion speed

– Intermittent

extrusion blow molding

• During the

process, the extruder

is stopped during

the time that

the

molding

occur

• use

either reciprocating screw or an accumulator system

• In this

system, the output of the extruder is matched by having multiple molds which

seal and blow the parison and then move away from extruder to cool and eject

• In

practical case, the mold cycle is longer than time required to extrude a new

parison

• If the

mold cycle is twice than time needed for creating a parison, a two mold system

can be used

• The

method is sometimes called rising mold system - system of which two or more

molds are used to mold parts from one extruder during continuous process

b)Injection

Blow Molding

• The

parison is formed by the injection of molten resin into a mold cavity and

around a core pin

• The

parison is not a finished product, but it is subjected to subsequent step to

form the final shape

• Second

step, blowing of the intermediate part in a second mold

• Because

of distinct separation of the two steps, the parison made by injection molding

is called a perform

Process

• The mold

is closed

• Resin is

then injected to form a cylindrical part

• The mold

is opened and perform is ejected

The

perform can be stored until the finished blow molded is needed.

The flexibility

of separating the two cycles has proven useful in manufacture of soda pop

bottle.

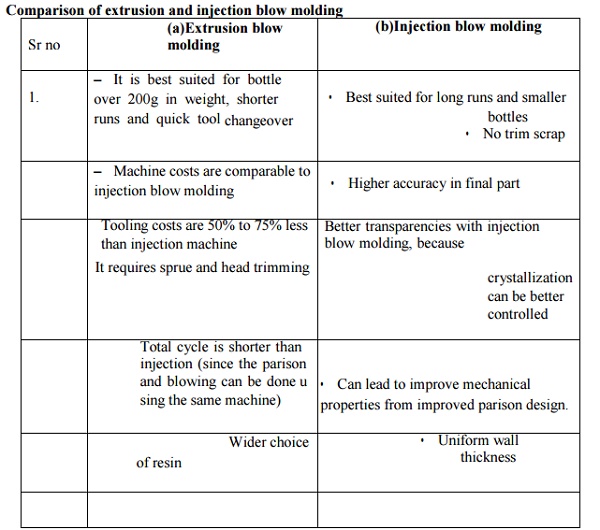

Comparison

of extrusion and injection blow molding

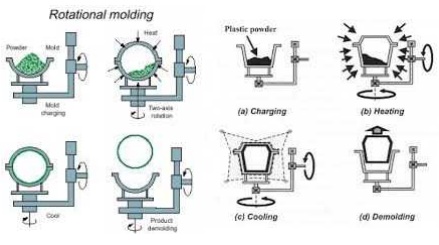

ROTATIONAL

MOULDING

It is also known as Rotomoulding, rotocasting or spin casting.

The thin walled metal mould is a

split female mould made of two pieces and is designed to be rotated about two

perpendicular axes. The steps followed in rotational moulding are.

STEP-1

A predetermined amount of plastic , powder or liquid form , is

deposited in one half of a mould.

STEP – 2

The mould is closed.

STEP -3

The mould is rotated biaxially

inside an oven. The hollow part should be rotated through two or more axes,

rotating at different speeds, in order to avoid the accumulatiuon of polymer

powder.

STEP – 4

The plastic melts and forms a coating over the inside surface of the mould.

STEP -5

The mould

is removed from the oven and cooled usually by fan. The polymer must be cooled

so that it solidifies and can be handled safely by the operator.The part will

shrink on cooling, coming away from the mould and facilitating easy removal of

the part.

STEP-6

The part

is removed from the mould.

Advantages of rotational moulding

1. Moulds

are relatively inexpensive.

2. Different

parts can be moulded at same time. 3.Very large hollow parts can be made.

4.Parts are stress free.

5.Very little scrap is produced.

Limitations of rotational moulding.

1.Moulding Cycles are long 10-20 mins

2.It is not possible to make some

sharp threads. 3.Cannot make parts with tight tolerance.

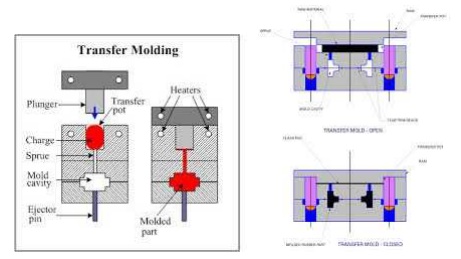

TRANSFER

MOULDING

Transfer

Molding

A process of forming articles by fusing a plastic

material in a chamber then forcing the whole mass into a hot mold to solidify.

Used to make products such as

electrical wall receptacles and circuit breakers

Similar to compression molding except

thermosetting charge is forced into a heated mold cavity using a ram or

plunger.

Examples:

electrical switchgear, structural parts

Process

Variables

• Amount of

charge

• Molding

pressure

• Closing

speed

• Mold

temperature

• Charge

temperature

• Cycle

time

Advantages

• Little

waste (no gates, sprues, or runners in many molds)

• Lower

tooling cost than injection molding

• Good

surface finish

• Less

damage to fibers

• Process

may be automated or hand-operated

• Material

flow is short, less

Disadvantages

• High

initial capital investment

• Labor

intensive

• Secondary

operations maybe required

• Long

molding cycles may be needed.

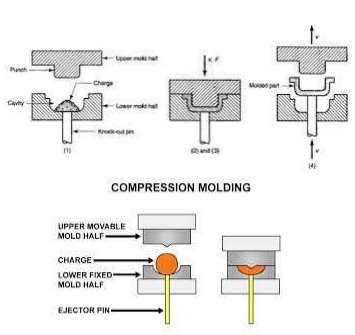

COMPRESSION MOULDING.

Compression

Molding

• The process of molding a material in a

confined shape by applying pressure and usually heat.

• Almost

exclusively for thermoset materials

• Used to

produce mainly electrical products

Thermoset

granules are “compressed” in a

heated mold to shape required.

Examples:

plugs, pot handles, dishware

Applications

of compression moulding.

1.Dishes , Handles , container caps, fittings, electrical and

electronic components.

2.Scoops, spoilers, hoods, fenders.

3.Polyester fiber glass resin systems (SMC/BMC)

Related Topics