Chapter: Mechanical : Manufacturing Technology : Manufacturing of Plastic Components

Blow Moulding

BLOW MOULDING

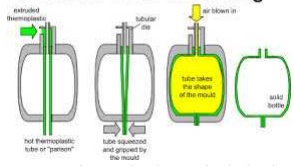

used to make thermoplastic bottles and hollow sections. Starting material is a round heated solid-bottom hollow tube – perform.

Perform inserted into two die halves and air is blown inside to complete the process

General steps

• Melting the resin- done in extruder

• Form the molten resin into a cylinder or tube (this tube is called parison)

• The parison is placed inside a mold, and inflated so that the plastic is pushed outward

against the cavity wall

• The part is allowed to cool in the mold and is then ejected

• The part is trimmed

The parison can be formed by

A)Extrusion process

B)Injection molding process

(A)Extrusion blow molding

– Parison is formed from by forcing the plastic through an extrusion

die.

Material enters the die, flow around the mandrel so that extrudate would be cylindrical

– The die would have a hole at the center so that air could be blown into the cylinder

– In some blow molding operations, the air is introduced from the bottom through an inlet

This process can be;

– continuous extrusion blow molding

• During the process, the extrusion runs continuously, thus making a

continuous parison.

• using multiple mold to match the mold cycle to the extrusion speed

– Intermittent extrusion blow molding

• During the process, the extruder is stopped during the time that the

molding occur

• use either reciprocating screw or an accumulator system

• In this system, the output of the extruder is matched by having multiple molds which seal and blow the parison and then move away from extruder to cool and eject

• In practical case, the mold cycle is longer than time required to extrude a new parison

• If the mold cycle is twice than time needed for creating a parison, a two mold system can be used

• The method is sometimes called rising mold system - system of which two or more molds are used to mold parts from one extruder during continuous process

b)Injection Blow Molding

• The parison is formed by the injection of molten resin into a mold cavity and around a core pin

• The parison is not a finished product, but it is subjected to subsequent step to form the final shape

• Second step, blowing of the intermediate part in a second mold

• Because of distinct separation of the two steps, the parison made by injection molding is called a perform

Process

• The mold is closed

• Resin is then injected to form a cylindrical part

• The mold is opened and perform is ejected

The perform can be stored until the finished blow molded is needed.

The flexibility of separating the two cycles has proven useful in manufacture of soda pop bottle.

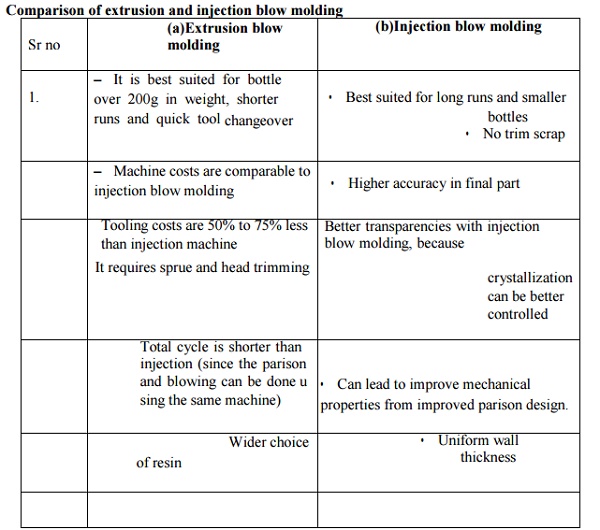

Comparison of extrusion and injection blow molding

Related Topics