Chapter: Civil : Prefabricated Structures : Joint In Structural Members

Joint In Structural Members: Types of Structure

Types of Structure

1. Fame less

- large paneled structures - External and Internal

wall panels - Floor and roof panels (of room single)

2. Framed

buildings : Columns, beams & floor elements.

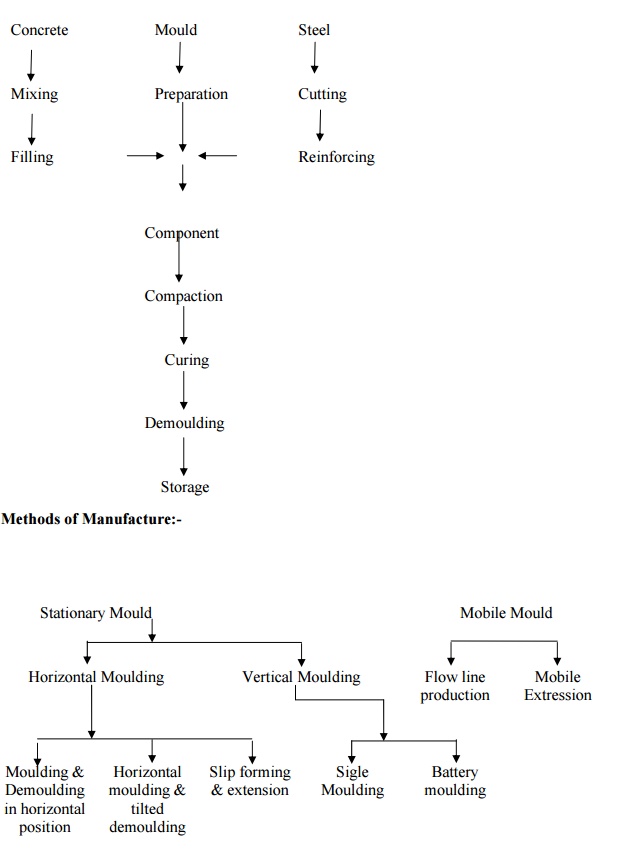

Stages of work in pre-casting

On -SITE : Open yard casting or

covered but purely temporary or semi-permanent type of set-up with partly

mechanized facilities.

Factors

Influencing method of manufacture

The

single and the total no of elements to be produced

1. The

single of the element may decide the reinforcement of space for production as

well as the capacity of the handling equipment is decided by the heorist

element.

Desired

rate of output: This will have direct bearing on the nf of moulds required

degree of mechanization and need for accelerated method of curving.

3. Shape,

type and construction features of these elements

Features such as special shares, projected reinforcement,

required finish on the surface on single layer or multi layer largely influence

the design of the mould and technical castings.

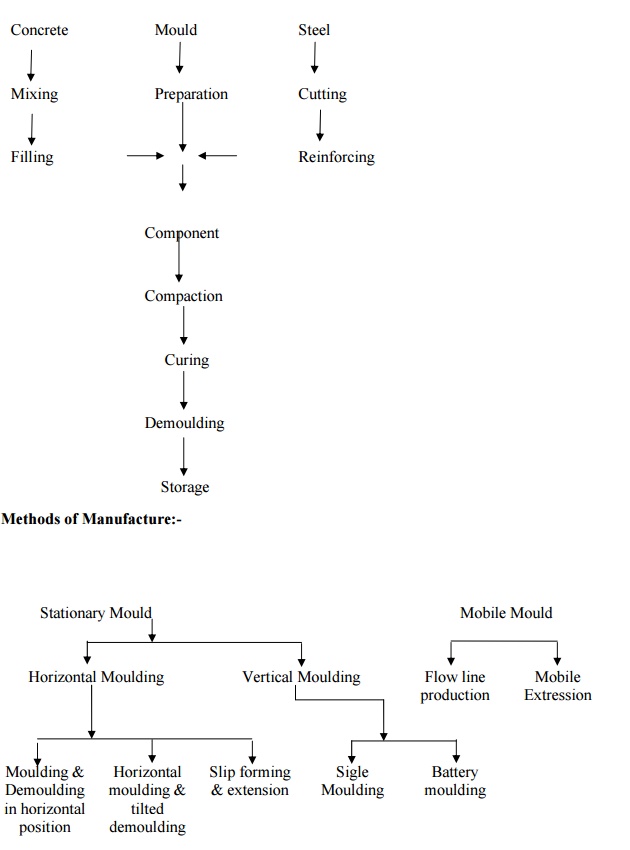

Horizontal casting techniques are favoured for curved

elements, multi larged elements and element which require some particular

finish vertical casting is favoured for single layer solid panel which require

no special finish on their surfaces.

4. Facilities

available in the production set u : An accelerated curing facility will result

in quick turn over of mould which can be advantageously used. Machineries like

over head gantry crane, will aid speedly production in handling.

5. Economic

aspects : The cost of production should be minimum.

Both moulding and demoulding in horizontal position -External

panel wall ; floor panes with protruded reinforcements, beams, columns, etc.

-Extra

reinforcements to take ease of bending stresses.

Tilting

Moulds :

Demoulding

is carried out in almost vertical position. No extra reinforcement is

necessary.

One end is hinged and the other end is lifted with

the aid of a fack or lifting equipment.

Slip

forming & Extrusion:

This method is achieved with a moving machine

mould which forms the cross sectional shape of the element and the element

hardening at the point where it is moulded. Precast pre stressed floor elements

both solid & hollw are manufactured using this techniques.

Concrete

laying - slips (Concrete buckets of various capacities)

Spreading

- either manually or with a mechanical spreads.

Vibrating

- with the help of shutter vibrates.

Screening

- long & heavy wooden floats surface finishing - Travelling.

Related Topics