Chapter: Civil : Prefabricated Structures : Joint In Structural Members

Expansion joint and design

Expansion Joints

An expansion joint is an assembly

designed to safely absorb the heat-induced expansion and contraction of various

construction materials. To absorb vibration, or to allow movement due to ground

settlement or earthquakes. They are commonly found between sections of sidewalks,

bridges, railway tracks, pipeing systems, and other structures.

Expansion joint design:

A design specification shall be

prepared for each expansion joint application. Prior to writing the expansion

joint design specification it is imperative that the system designer completely

review the structural system layout, and other items which may affect the

performance of the expansion joint. Particular attention shall be given to the

following items.

The

system should be reviewed to determine the location and type of expansion joint

which is most suitable for the

application. Both the EJMA Standards and most reliable expansion

joint manufacturers'' catalogs provide numerous examples to assist the

user in this

effort. The availability of

supporting structures for anchoring and guiding of the system, and the

direction and magnitude of thermal movements to be absorbed must be considered

when selecting the type and location of the expansion joint.

Conventional rubber expansion joint

Expansion joints are designed to

provide stress relief in piping systems that are loaded by thermal movements

and mechanical vibration. To deal with the various forces on the joint they

require fibre reinforcement which guarantees both flexibility and strength.

Conventional expansion joints are reinforced using prefabricated fibre plies.

The use of these fabric plies makes it impossible to control the orientation of

the fibres on complex shapes such as the bellow of an expansion joint. In both

cases the inability to use the fibres in an optimal way leads to the following

disadvantages:

High Material Cost:

v More

fibres needed than necessary

v More

rubber needed than necessary

v Additional

parts such as metal reinforcement rings necessary with multiple bellows Lower

Performance

v High

rubber wall thickness and fibre pack make product less flexible

v Undesired

radial and axial expansion under pressure.

1) Introduction

2)

Necessity

3)

Advantages

4) Pre

requisites

5) Types

of prefabrications

Pre-fabrication means that the structure is disunited in its

disunited in its members and these are precast in factor built and equipped

particularly this purpose or in temporary plants establish on the site. Then

the precast reinforced core members are shipped to the place where they used.

Here they are hoisted set into their fix places and assembled in the form of a

complete structure. The stages involved are

1) The

structure is divided into no of units.

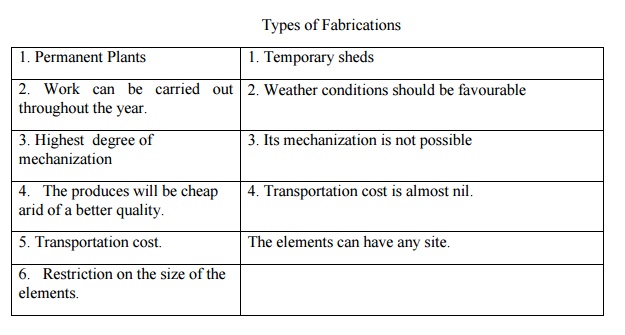

2) The

different units are precast in permanent plants. Permanent prefabrications -

plant prefabrication. Temporary plants (sheds) - Site prefabrication

3) Transported

to the site

4) Hoisted

and put into their places Prefabrications eliminates the use of scaffle.

Necessity:

Million

houses in rural areas.

20 million

houses in urban areas speedier construction.

Conventinal

methods - time consuming

- The

components are not a man power is not effectively.

Factors:

1) Cellular

concrete plant at Madras

2) Hindustan

Housing Factory at New

3) SIPOREX,

India Limited at Poona

4) Key Jay

Spirole private limited.

In New

Delhi they are manufacturing -sleepers & poles.

Object or

AIM :

1) To

accelerate the building construction.

2) To

increase the building activity.

To

effectively utilize the man power. Pre-Requisite:

1. Large

demand of flats in a limired area

2. Availability

of adequate funds & buildings materials

3) Prospective

planning of building activities and long time orders.

4) Standardization

allowing mass production

5) Adequate

mechanization of production process.

Related Topics