Geography - Industries in India | 10th Social Science : Geography : Chapter 4 : India - Resources and Industries

Chapter: 10th Social Science : Geography : Chapter 4 : India - Resources and Industries

Industries in India

Industries

It refers

to the activities which converts the raw materials into finished products. This

sector is called as the value addition sector. On the basis of the source of

raw materials, Industries are classified into the Agro based industries, Forest

based industries and Mineral based industries.

Agro based industries

These industries draw their raw materials from agricultural sector. The following part discusses the agro based industries in India.

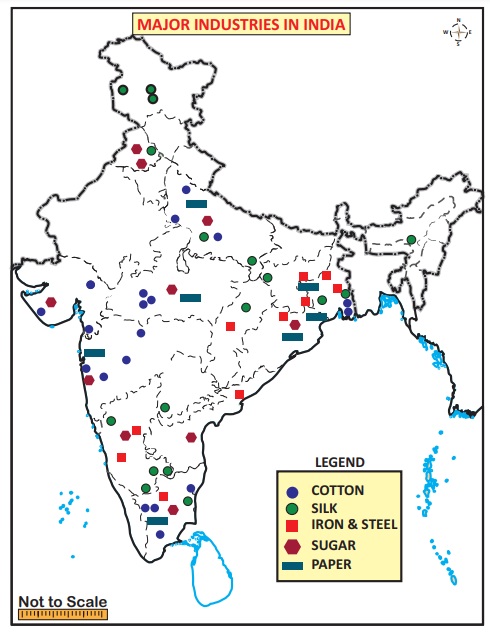

a) Cotton Textile Industry

Textile

is a broad term which includes cotton, jute, wool, silk and synthetic fibre

textiles. This sector in India is the second largest in the world.

The first cotton textile mill was established at Fort Gloster

near Kolkata in 1818.

Traditional

sectors like hand loom, handicrafts and small power-loom units are the biggest

source of employment for millions of people in rural and semi urban areas.

Currently,

India is the third largest producer of cotton and has the largest loom arc and

ring spindles in the world. At present, cotton textile industry is the largest

organized modern industry of India.

Ginning is the process of separating cotton seed from cotton.

The higher concentration of textile mills in and around Mumbai, makes it as “Manchester of India”. Presence of black cotton soil in Maharastra, humid climate, presence of Mumbai port, availability of hydro power, good market and well developed transport facility favour the cotton textile industries in Mumbai.

The major cotton textile industries are concentrated in the states of Maharashtra, Gujarat, West Bengal, Uttar Pradesh and Tamil nadu. Coimbatore is the most important centre in Tamil nadu with 200 mills out of its 435 and called as “Manchester of South India”. Erode, Tirupur, Karur, Chennai, Thirunelveli, Madurai, Thoothukudi, Salem and Virudhunagar are the other major cotton textiles centres in the state.

b) Jute Textiles

Jute is a

low priced fibre used mainly for making package materials like gunny bags.

Today jute is blended with cotton and wool to produce textiles. This is the

second important textile industry in India after cotton textiles. Jute is the

golden fibre which meets all the standards of goods packing with its natural,

renewable, bio degradable and eco-friendly products.

The first

jute mill in India was established at Rishra near, Kolkata in 1854 by the

English man George Auckland. India tops in the production of raw jute and jute

goods and second in the export of jute goods next to Bangladesh. Jute

production includes gunny bags, canvas, pack sheets, jute web, carpets,

cordage, hessians and twines. Now jute is also being used in plastic furniture

and insulation bleached fibres to blend with wool. It is also mixed with cotton

to make carpet and blankets. The major jute producing areas are in West Bengal

and concentrated along the Hooghly river within the radius of six kilometre of

Kolkata. Titagarh, Jagatdat, Budge-Budge, Haora and Bhadreshwar are the chief

centres of jute industry. Andhra Pradesh, Bihar, Uttar Pradesh, Assam,

Chhattisgarh and Odisha are the other jute goods producing areas.

National jute board is headquarter at Kolkata.

CSTRI is the only research institute in the country dedicated to

the Research

Developmental activities related to

silk technology. CSTRI was established in the year 1983 by the Central Silk

Board, Ministry of Textiles, Govt. of India having head quarter at Bengaluru

c) Silk Industry

India has been well known for the production of

silk since the ancient times. India is the second largest producer of raw silk

next only to China.

Karnataka is the largest producer of silk. Other

major producers of silk are West Bengal, Jammu Kashmir, Bihar, Jharkhand,

Chhattisgarh, Uttar Pradesh, Punjab, Assam and Tamil nadu states.

Office of the Development Commissioner for Handlooms was set up as an attached non-participating office on 20th November, 1975 under the Ministry of Commerce. At present it is functioning under the Ministry of Textiles, headquarters at Udyog Bhawan, New Delhi.

d) Sugar Industry

Sugar can

be produced from sugar cane, sugar-beets or any other crop which have sugar

content. In India, sugar cane is the main source of sugar. At present this is

the second largest agro based industry of India after cotton textiles. India is

the world’s second largest producer of sugar cane after Brazil. Sugar industry

is decentralized and located near the sugarcane growing areas as they are

weight loosing and bulky to transport.

Uttar Pradesh is the largest producer of sugar,

producing about 50% of the country’s total. Other major producers are

Maharashtra, Uttar Pradesh, Karnataka, Andhra Pradesh, Tamil nadu, Bihar,

Punjab, Gujarat, Haryana and Madhya Pradesh states. These states account for

more than 90% of the sugar mills and sugar production.

Forest based industries

Forest provide us with different types of material which are used as raw material for certain industries like paper, lac, sports goods, plywood etc.

a) Paper industry

Paper Industry produces numerous types of papers

that comes in various use such as sheet paper,paperboxes,tissues,paperbags,stationery,

envelopes and printed-paper products such as books, periodicals, and

newspapers. In India the Soft wood is the principal raw material used for

making paper especially newsprint and high class printing papers. Paper is the

pre-requisite for education and literacy and its use is an index of advancement

in these two fields as well as the overall well being of the society.

The first paper mill of India was

started in 1812 at Serampore in West Bengal.

The first successful effort was made in 1867 with

the setting up of the Royal Bengal paper mills at Ballyganj near Kolkata. The

raw materials for paper industry includes wood pulp, bamboo, salai and sabai

grasses, waste paper and bagasse. West Bengal is the largest producer of paper

in the country followed by Madhya Pradesh, Odisha and Tamil nadu.

National Newsprint and Paper Mills

(NEPA) is at Nepanagar in Burhanpur District of Madhya Pradesh.

Mineral based industries

Mineral based industries use both metallic & non metallic minerals as raw materials. The major mineral based industry of country is the iron steel industry

a) Iron and steel industries

Iron and steel industry is called a basic

metallurgical industry as its finished product is used as raw material by host

of other industries. Several industries like engineering, heavy machines and

machine tools, automobile, locomotives and railway equipment industries use

iron and steel as their primary raw material. Due to this, the steel producing

capacity of a country is generally taken as an indicator of its level of

industrial development.

The first attempt to produce iron and

steel unit was set up at Porto Novo in Tamil nadu in 1830.

The

modernization of the industry was started in 1907 with the establishment of

Tata Iron and Steel Company at Sakchi, now called Jamshedpur. Iron and steel

industry of India is mainly concentrated in the states of Jharkhand, West

Bengal and Odisha. Proximity to the coal fields of Jharia, Raniganj, Bokaro and

Karanpura and the iron ore mines of Mayurbhanj, Keonjar and Brona are

responsible for this. This area also has sufficient deposits of limestone,

dolomite, manganese and silicon which are required for the industry.

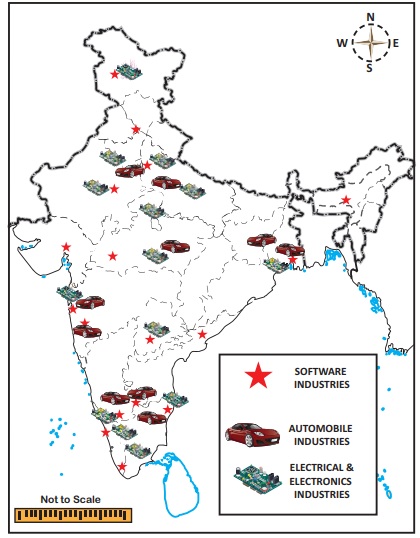

Automobile Industry

India is

set to emerge not only as a large domestic market for automobile manufacturers,

but also as a crucial link in the global automotive chain. It is one of the

most dynamic industrial groups in India.

The first automobile industry of India was started

in 1947. The industry is the Premier Automobiles Ltd located at Kurla (Mumbai).

It was followed by the Hindustan Motors Ltd at Uttarpara (Kolkata) in 1948. At

present, India is the 7th largest producer of automobile manufacturers which

include two wheelers, commercial vehicles, passenger car, jeep, scooty,

scooters, motor cycles, mopeds and three wheelers. Major centres are at Mumbai,

Chennai, Jamshedpur, Jabalpur, Kolkata, Pune, New Delhi, Kanpur, Bengaluru,

Sadara, Lucknow and Mysuru.

Chennai is nicknamed as the “Detroit

of Asia” due to the presence of major automobile manufacturing units and allied

industries around the city.

Tata Motors, Maruti Suzuki, Mahindra & Mahindra

and Hindustan Motors are the largest passenger car manufacturers of Indian

companies in the country. Presence of foreign car companies such as Mercedes

Benz, Fiat, General Motors, Toyota and the recent entry of passenger car

manufacturers BMW, Audi, Volkswagen and Volvo makes the Indian automobile

sector a special one. Tata Motors, Ashok Leyland, Eicher Motors, Mahindra &

Mahindra and Ford Motors are the major Indian companies which manfacture

commercial vehicles. MAN, ITEC, Mercedes-Benz, Scania and Hyundai are the

foreign companies engage in the manfacture of commercial vehicles. Two-wheeler

manufacturing is dominated by Indian companies like Hero, Bajaj Auto and TVS.

Electrical and Electronic Industries

Heavy

electrical industries manufacture equipment used for power generation,

transmission and utilization. Turbines for steam and hydro power plants, boilers

for thermal power plants, generators, transformers, switch gears etc. are the

chief products of this industry. The most important company in the field of

heavy electrical is Bharat Heavy Electricals Ltd (BHEL). It has its plants at

Hardwar, Bhopal, Hyderabad, Jammu, Bengaluru, Jhansi and Tiruchirappalli. This

Industry covers a wide range of products including television sets, transistor

sets, telephone exchanges, cellular telegram, computers and varied equipments

for post and railway, defence and meteorological department.

Bengaluru is the largest producer of electronic

goods in India, hence it is called as the “Electronic Capital of India”. The

other major producers of electronic goods centers are Hyderabad, Delhi, Mumbai,

Chennai, Kolkata, Kanpur, Pune, Lucknow, Jaipur and Coimbatore.

Make in India program was launched in

2014 to put India on the world map as a major hub for global design and

manufacturing.

Software Industry

India is

home to some of the finest software companies in the world. The software

companies in India are reputed across the globe for their efficient IT and

business related solutions. The Indian Software Industry has brought about a

tremendous success for the emerging economy.

In India, software industry began in 1970 with the

entry of Tata Consultancy Services (TCS). Along with this, L & T, Infotech,

i-Flex, Accenture, Cognizant, GalexE Solutions India Pvt Ltd and ITC Infotech

are the major software industries in the country. At present, there are more

than 500 software companies all over India. It exports software service to

nearly 95 countries in the world.

The main

centres of IT parks are located in Chennai, Coimbatore, Thiruvananthapuram, Bengaluru,

Mysuru, Hyderabad, Visakhapatnam, Mumbai, Pune, Indore, Gandhi Nagar, Jaipur,

Noida, Mohali and Srinagar.

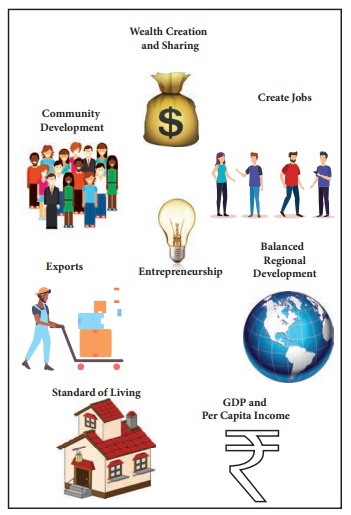

Major challenges of Indian Industries

Industries

in India face many problems.

Some

major problems are listed below.

• Shortage and fluctuation in Power Supply.

• Non- availability of large blocks of land.

• Poor access to credit.

• High rate of interest for borrowed loan.

• Non- availability of cheap labourers.

• Lack of technical and vocational training for

employees.

• Inappropriate living conditions nearby industrial

estates.

Related Topics