Chapter: Chemistry : Water Technology

Important Questions and Answers: Water Technology

01. Define boiler feed water.

The water

fed into the boiler for the production of steam is known as boiler feed water.

02. What are the requirements of boiler feed water?

It should

free from

(i).

Suspended solids. (ii). Dissolved salts like MgCl2

(iii).

Hardness. (iv). Alkalinity. (v). Dissolved gases like O2 and CO2

03. What are the disadvantages using hard water in

boiler?

Scale and

sludge formation. 2. Caustic

Embrittlement.

3.

Priming and Foaming. 4. Boiler

corrosion.

04. What are the disadvantages formation of

deposits in steam boilers and heat exchangers?

Wastage

of fuels. 2. Decrease in efficiency. 3. Boiler explosion.

05. Define Boiler explosion.

When

thick scales crack due to uneven expansion, the water comes suddenly in contact

with over-heated iron plates. This causes in formation of a large amount of

steam suddenly. So sudden high-pressure is developed, which may even cause

explosion of the boiler.

06. What are the methods used to be prevention of

scale formation?

Prevention

of scales formation: (i).

External Treatment – zeolite process

(ii).

Internal Treatment.- carbonate conditioning.

07. What are the methods used to be softening hard

water?

(i).

External Treatment – zeolite process, Demineralisation process (ii). Internal

Treatment.- carbonate conditioning, calgon conditioning.

08. What is meant by internal conditioning of

water? Give one example.

Treating

the boiler water in the boiler itself by adding chemicals to remove scale

forming substance is called internal conditioning.

Ex:

carbonate conditioning, phosphate conditioning, calgon conditioning.

09. What is meant by external conditioning of

water? Give one example.

Treating

the boiler water before feeding it into boiler is called external conditioning.

Ex: zeolite process, Demineralisation process

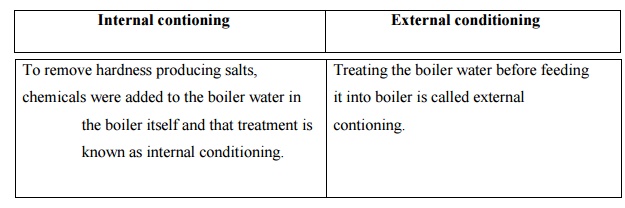

10. Distinguish between internal contioning and

external conditioning methods.

Internal contioning

To remove hardness producing salts, chemicals were added to the

boiler water in the boiler itself and that treatment is known as internal

conditioning.

External conditioning

Treating the boiler water before feeding it into boiler is

called external contioning.

11. What is meant by caustic embrittlement? How is

it prevented?

Caustic

embrittlement means intercrystalline cracking of boiler metal. It is prevented

by using softening agent like sodium phosphate and by adding tannin and lignin.

12. What is desalination?

The

process of removing common salt (NaCl) from the water is known as desalination.

The water contains dissolved salts with brackish taste is called brackish

water.

Desalination

= Removal of common salt (NaCl ) from water

13. What are boiler compounds? Mention two

different boiler compounds and their actions.

The

chemicals directly added into the boiler for removing scale forming substances

is known as boiler compounds. Ex: Sodium carbonate and Sodium phosphate

14. What is Calgon? How does it function in water

treatment?

Calgon –

Sodium Hexa Meta Phosphate

It

interacts with calcium ions forming a highly soluble complex and thus prevents

the precipitation of scale forming salt.

15. What is Reverse osmosis?

When two

solutions of different concentrations are separated by a semipermeable

membrane, when a pressure is applied on the concentrated side, the solvent flow

from higher concentration to lower concentration.

16. What are the advantages of reverse osmosis method?

Low

capital cost, easy operating.

RO method

is used for converting sea water into drinking water.

It

removes all types of impurities like non-ionic and colloidal.

The life

time of membrane is high and it can be replaced within few minutes.

01. Define Boiler Feed Water. What are the

requirements of Boiler Feed Water?

Boiler Feed Water: The

water fed into boiler for the production of steam is called boiler feed water.

It should

be free from turbidity, oil, dissolved gases, alkali and hardness producing

substances.

Requirements

of Boiler Feed Water:

i). It

should has zero hardness.

If

hardness present in boiler feed water, it produces scales and sludges, which

prevents efficient heat transfer.

ii). It

must free from dissolved gases like O2 and CO2.

![]()

If

dissolved gases present in boiler feed water, it leads to boiler corrosion.

iii). It

should be free from suspended impurities.

If it is

present in boiler feed water, it produces wet steam.

iv). It

should be free from dissolved salts and alkalinity.

If it is

present in boiler feed water, it produces caustic embrittlement, which causes

brittlement of boiler parts.

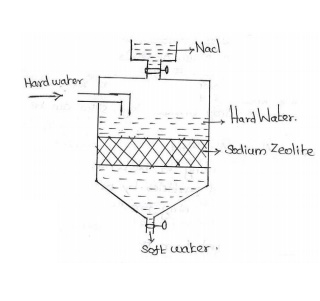

Zeolite:Sodium

Aluminum Orthosilicate.

Na2O.Al2O3.xSiO2YH2O.

The

synthetic form of zeolite is known as PERMUTIT, which is porous and possess gel

structure and Ze stands for insoluble zeolite.

Principle:

The sodium ions which are loosely held in Na2Ze are replaced by Ca2+ and Mg2+

ions present in water.

Process: When

hard water is passed through a bed of zeolite placed in a closed cylinder, the

hardness causing ions like Ca2+ and Mg2+ ions are taken

up by zeolite. Sodium salts are released during the reaction as byproduct.

For softening of water by zeolite process, hard water is percolated at a

specified rate through a bed of zeolite, kept in a cylinder.

The hardness causing ions like Ca2+ and Mg2+are

retained by the zeolite as CaZe and MgZe. While the outgoing water contains

sodium salts.

The

various reactions taking place may be

Na2Ze

+ Ca(HCO)2 -- --- > CaZe + 2NaHCO3

Na2Ze

+ Mg(HCO)2 -- --- > MgZe +

2NaHCO3

Na2Ze + MgCl2 -- --- > MgZe +

2NaCl

![]() Na2Ze + CaCl2 -- --- > CaZe + 2NaCl

Na2Ze + CaCl2 -- --- > CaZe + 2NaCl

Na2Ze

+ CaSO4 -- --- > CaZe

+ Na 2SO4

Na2Ze

+ MgSO4 -- --- > MgZe

+ Na 2SO4

Regeration

After some time zeolite gets exhausted. The exhausted zeolite is

again regerated by treating with 10%solution of NaCl.

CaZe + 2 NaCl → Na2Ze + CaCl2

MgZe + 2 NaCl → Na2Ze

+MgCl2

Advantages: (i). Output water has only 1-2 ppm.

(ii). Operation is easy.

(iii). No

sludge is formed during the process.

03. Explain formation of deposits

in steam boilers and heat exchangers.

Steamboilers: Sealed

vessel where water is converted to steam.

A steam

boiler is a type of generator that is used to create steam.

Heat

exchangers: A device for transferring heat from one medium to

another.

Heat

exchangers are designed to remove excess heat from aircraft

engines, optics, x-ray tubes, lasers, power supplies, military equipment, and many other types of equipment

that require cooling beyond what air-cooled heat sinks can provide.

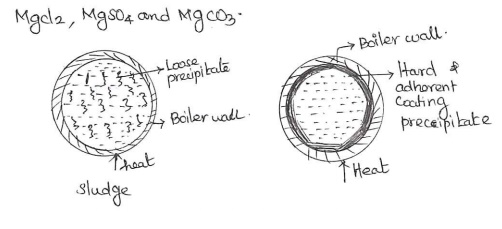

Formation

of deposits: Scale and sludge formation.

Scale:If the

precipitate forms hard and adherent coating on the inner walls of the boiler is

known as scale. It is formed by the

substances like CaSO4, Mg(OH)2 and Ca(HCO3)2.

Scales

are difficult to remove even with the help of hammer and chisel. Scales are the

main sources of boiler troubles. Formation

of scales

may be due to

(i).

Decomposition of calcium bicarbonate. (ii). Deposition of calcium sulphate.

(iii).

Hydrolysis of magnesium salts. (iv). Presence of silica.

Sludge: In boiler, water contains the

precipitate loose and slimy is known as sludge. It is formed by the substances like CaCl2, MgCl2, MgSO4 and MgCO3.

Disadvantages:

(i). Poor

conductor of heat.

(ii).

Excessive sludge formation disturbs the working of the boiler.

(iii). It

forms along with scales, then former gets entrapped in the latter and both get

deposited scales.

Prevention

of sludge formation: (i). By using well softened water.

(ii). By

frequently below down opearation.

04. What are the disadvantages in

scale formation? Explain in detail.(Or)

What are the disadvantages formation

of deposits in steam boilers and heat exchangers?(or)

Write short notes on (i). Wastage

of fuels. (ii). Decrease in efficiency. (iii). Boiler Explosion.

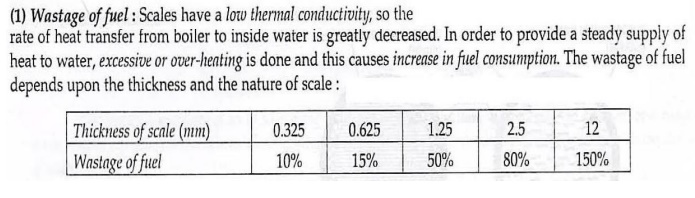

Disadvantages: (i).

Wastage of fuels.

(ii).

Decrease in

efficiency.

(iii). Boiler

Explosion.

(i). Wastage of fuels:

(ii). Decrease in efficiency:

Scales may sometimes deposit in the valves and

condensers of the boiler and choke then partially. This results in decrease in

efficiency of the boiler.

(iii). Boiler Explosion:

When thick scales crack due to uneven expansion,

the water comes suddenly in contact with over-heated iron plates. This causes

in formation of a large amount of steam suddenly. So sudden high-pressure is

developed, which may even cause explosion of the boiler.

6. Explain prevention of scales

formation.

Prevention of scales formation: (i). External Treatment.

(ii).

Internal Treatment.

(i).

External Treatment:Softening of water (i.e) removing hardness-

producing constituents of water. Ex: Zeolite process and Demineralization

process.

(ii).

Internal Treatment:Sequestration

process.

An ion is prohibited to exhibit its original

character by complexing or converting it into other more soluble salt by adding

suitable reagent.

An

internal treatment – by adding proper chemical to the boiler water either

(a). To

precipitate the scale forming impurities in the form of sludge, which can be

remove by blow – down operation (or)

(b). To

convert them into compounds, which will stay in dissolved form in water and

thus do not cause any harm Blow down operation: It is partial removal of hard

water through top at the bottom of boiler, when extent of hardness in the

boiler becomes alarmingly high.

Internal

treatments methods are, generally, followed by blow-down operation , so that

accumulated sludge is removed. Internal treatment methods are,

(i).

Colloidal Conditioning

(ii).

Phosphate Conditioning

(iii).

Carbonate Conditioning

(iv).

Calgon Conditioning.

07. Write short notes on Caustic Embrittlement.

Caustic

Embrittlement. = Intercrystalline cracking of boiler metal

It is a

type of boiler corrosion, caused by using highly alkaline water in the boiler.

In boiler

water, it contains a small amount of sodium Carbonate. In high pressure, it

decomposes to give sodium hydroxide.

Na2CO3 + H2O

--- 2NaOH + CO2

Then this

NaOH reacts with boiler material and it forms sodium Ferrate and this leads to

brittlement of boiler parts like joints, bends etc.,

Fe +2NaOH --- Na2FeO2

+ H2

It is prevented by or

Avoided by

(i). By

using sodium phosphate as softening reagent instead of sodium carbonate. (ii).

By adding Tannin or Lignin to boiler water for blocks hair-cracks.

(iii). By

adding sodium sulphate to boiler water also blocks hair-cracks.

08. Explain Internal conditioning

methods of softening hard water.

To remove

hardness producing salts, chemicals were added to the boiler water in the

boiler itself and

that

treatment is called internal conditioning.

(i).

Colloidal Conditioning (ii). Phosphate Conditioning

(iii).

Carbonate Conditioning (iv). Calgon Conditioning.

(i)

Colloidal Conditioning:

In low-pressure

boilers, scale formation

can be avoided

by adding organic

substances like kerosene ,tannin,

agar-agar (a gel), etc., which get coated over the scale forming precipitates,

thereby yielding non-sticky and loose deposits, which can easily be removed by

pre-determined blow-down operations.

(ii). Phosphate

conditioning:

Three types

of phosphates- mono, di and trisodium

phosphates are employed

in phosphate conditioning. The advantages of phosphate conditioning over

carborate conditioning are

(i). It

can be applied to high pressure boilers and

(ii) It

can be used for softening/ conditioning acidic, neutral or alkaline water

sample.

If acidic

water is to be conditioned, trisodium phosphate can be used. For neutral and

alkaline water samples disodium phosphate and monosodium phosphate can be used

respectively.

(iii)

Carbonate conditioning:

In low

pressure boilers, calcium ions are converted into soft and loose sludge by

adding sodium carbonate solution. It forms soft CaCO3 which can be removed by

blow-down operation.

Calgon

conditioning:

Calgon

interacts with calcium ions forming a highly soluble complex and it prevents

the

Calgon=Sodium HexaMeta phospha)6precipitation of scale forming salt. The complex Na2[Na4(PO3)6]

is soluble in water and no problem for its sludge disposal.

Write short

notes on Boiler corrosion / Explain boiler corrosion in detail / Write short

notes on Boiler troubles – Boiler corrosion.

Boiler

corrosion taken place in boiler in the presenceë of gases like dissolved oxygen,û dissolved CO2 and dissolved salts.

Dissolved oxygen: It

attacks the boiler material at high temperature and causes the Corrosion.

4Fe +6H2O + 3O2

--- > 4Fe(OH)3

It is removed by chemical and mechanical method. Chemical

Method: Sodium sulphite, Hydrazine used to remove dissolved oxygen. Mechanical

Method: To remove by De-aeration method.

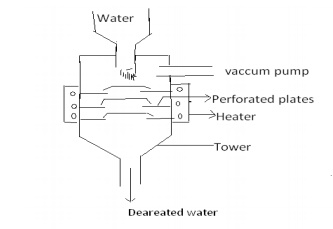

Water

spraying in a perforated plate-fitted tower, heated from sides and connected to

vaccum pump. High temperature, low pressure and large exposed surface reduces

the dissolved oxygen in water.

Dissolved CO2: It produces carbonic acid, which is acidic

and corrosive in nature

CO2 +H2O

--- H2CO3 (Carbonic acid )

It can be

removed by adding calculated amount of NH4OH into water and also removed by

de-aeration method.

Dissolved salts(MgCl2): Salts

like CaCl2 and MgCl2 undergoes hydrolysis at higher temperature , to give

HCl , which corrodes the boiler

MgCl2

+ 2H2O --- Mg(OH)2 +2HCl

Fe +2HCl ---

FeCl2 + H2

FeCl2 + 2H2O

---- Fe(OH)2 +2HCl

It can be

avoided by adding alkali into the boiler water.

10. Explain priming and foaming

(carry over).

1.Priming: It

is the process of production of wet steam.

Wet steam

– Steam contains droplets of liquid water

It is

caused by

High

steam velocity

Very high level water in the boiler

Sudden boiling of water

iv).Very

poor boiler design.

Prevention: It is controlled by

Controlling the velocity of steam

Keeping the water level lower

Good boiler design

4) Using

treated water

2)

Foaming:

The

formation of stable bubbles above the surface of water is called foaming

These

bubbles are carried over by steam leading to excessive priming. It is caused by

Presence

of oil and grease

Presence of finely divided particles. It can be

prevented by

i).

Adding coagulants like sodium aluminate

ii).Adding

anti-foaming agents like synthetic polyamides.

11. What is Desalination? Describe desalination of

by Reverse Osmosis method with neat diagram.(or)Explain the reverse osmosis

process for desalination of brackish water in detail.

Desalination

= Removal of common salt-NaCl from

water.

Brackish

water = Water containing dissolved salts with a peculiar salty taste. Ex: Sea

water

Reverse

Osmosis(R

O):

When a

pressure greater than osmotic pressure applied on the concentrated side, the

solvent flow takes place from higher concentration to lower concentration is

known as reverse osmosis.

In this RO process, Pure water is separated from

salt water.

This RO process is also known as Super filtration

or Hyper filtration

When the pressure is applied from the higher

concentration side, the solvent flow takes place to lower side and these two

concentrations are separated by semipermeable membrane, the salt water is

converted into pure water.

The membranes used as cellulose acetate, polyamide

and some polymers.

Advantages &

RO method:

1. Low capital cost, easy operating.

2. It is

used for converting sea water into drinking water

3. It

removes all types of impurities like non-ionic and colloidal

4. The life

time of membrane is high and it can be replaced within few minutes.

Related Topics