Chapter: Mechanical : Manufacturing Technology : Metal Forming Process

Important Questions and Answers: Metal Forming Process

METAL

FORMING PROCESS

1 What are the four major drawbacks of hot

working?

Ans:

• As hot working is carried out at high

temperatures, a rapid oxidation orscale formation takes place on the metal

surface which leads to poor surface finish and loss of metal.

• Due to

the loss of carbon from the surface of the steel piece being worked, the

surface layer loses its strength.

• This

weakening of the surface layer may give rise to fatigue crack which results in

failure of the part.

• Close

tolerance cannot be obtained.

• Hot

working involves excessive expenditure on account of high tooling cost.

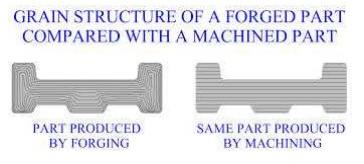

2. Explain why parts produced by Forging is preffered when compared to other

machining and welding process.

2 Classify the types of extrusion.

Ans:

Extrusion

1. Hot

Extrusion

2. Cold

Extrusion

3. Hot

extrusion

(A)Direct extrusion,(B) Indirect extrusion,(C)Tube

extrusion

3 What is the difference between a bloom

and a billet?

Ans: A bloom has a square cross section with minimum

size of 150x150 mm and a billetis smaller than bloom and it may have any square

section from 38 mm upto the size of a bloom.

4 What is impact extrusion ?

Ans: The raw material is in slug form which have been

turned from a bar or punched from

a strip. By using punch and dies, the operation is performed.

The slug is placed in the die and struck from top by the punch opareting at

high pressure and speed.

5 Why are a number of passes

required to roll a steel bar?

Ans: To reduce the thickness and to increase the width of the

bar number of passesare required.

6 How are seamless tubes produced?

Ans: Seamless tubing is a popular and

economical raw stock for machining because it

saves drilling and boring of parts. The piercing machine

consists of two rapered rolls, called as piercing rolls.

7 What is Sejournet process?

Ans: That

extrusion process which is based both on the use of a lubricantin a viscous

condition at extrusion temperature and on a separation between

the lubrication of the chamber wall and die is called Sejournet process.

8 What is skew rolling ?

Ans: The rolls are powered and the workpiece is in due to

frictional force between metal and surface. The torque on the rolls is being

zero.

9 Explain the term Extrusion

process.

Ans: The extrusion process consists of

compressing a metal inside achamber to

force itout

through a small opening which is called as die. Any plastic

material can be successfully extruded. A large number of extruded shapes which

are commonly used are tubes, rods, structural shapes and lead covered cables.

During the process, a heated cylindrical billet is placed in the container and

forced out through a steel die with the help of aramor plunger.

10 What are the disadvantages of

forging processes?

Ans:

•

Complicated shapes cannot be produced.

•

Generally used for large parts.

•

Because of cost of dies, process is costly.

11.Define

Impact extrusion.

Ans.It is a

cold working process of making required shape by striking slugs of metal by

high impact. It is used for making tooth paste ,shaving cream and

collapsible medicine tubes.

12.What is meant by cold

spinning.It is the operation of shaping very thin metals by pressing

against a form while it is rotating , It is carried out at room

temperature.

13.Define Hot Spinning.

It is the

process of making circular cross section or a dish or head from circular ,

heavy plates by spinning sheet metal.

14.What is wire drawing.

Drawing of metal through a small

aperture die and wounding in the form of coil is called wire drawing. The aperture

is generally below 16mm diameter.

15.What is meant by deep Drawing.

It is the process of making cup shaped parts from

sheet metal blanks, where the depth of the cup is greater than that of the

diameter of the cup.

Related Topics