Chapter: Mechanical : Manufacturing Technology : Metal Forming Process

Forging

FORGING

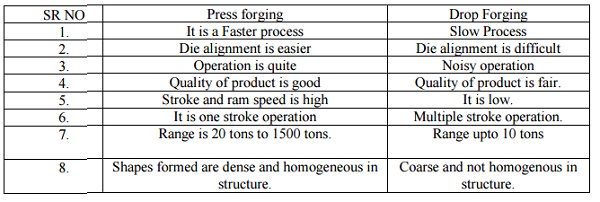

1. COMPARISON BETWEEN PRESS FORGING AND DROP FORGING.

SR NO Press forging : Drop Forging

1. It is a Faster process : Slow Process

2. Die alignment is easier : Die alignment is difficult

3. Operation is quite : Noisy operation

4. Quality of product is good : Quality of product is fair.

5. Stroke and ram speed is high : It is low.

6. It is one stroke operation : Multiple stroke operation.

7. Range is 20 tons to 1500 tons. : Range upto 10 tons

8. Shapes formed are dense and homogeneous in structure. : Coarse and not homogenous in structure.

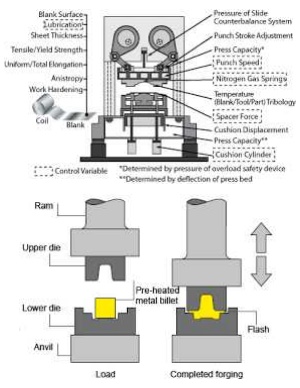

2. Forging operations

Forging is a process in which the work piece is shaped by compressive forces applied through various dies and tools. It is one of the oldest metalworking operations. Most forgings require a set of dies and a press or a forging hammer. A Forged metal can result in the following: -

Decrease in height, increase in section - open die forging Increase length, decrease cross-section, called drawing out.

Decrease length, increase in cross-section on a portion of the length - upsetting

Change length, change cross-section, by squeezing in closed impression dies - closed die forging. This results in favorable grain flow for strong parts

3. Types of forging

Closed/impression die forging

Electro-upsetting

Forward extrusion

Backward extrusion

Radial forging

Hobbing

Isothermal forging

Open-die forgig

Upsetting

Nosing

Coining

Commonly used materials include

• Ferrous materials: low carbon steels

• Nonferrous materials: copper, aluminum and their alloys

3.1Open-Die Forging

Open-die forging is a hot forging process in which metal is shaped by hammering or pressing between flat or simple contoured dies.

Equipment. Hydraulic presses, hammers.

Materials. Carbon and alloy steels, aluminum alloys, copper alloys, titanium alloys, all forgeable materials.

Process Variations. Slab forging, shaft forging, mandrel forging, ring forging, upsetting between flat or curved dies, drawing out.

Application. Forging ingots, large and bulky forgings, preforms for finished forgings.

Closed Die Forging

In this process, a billet is formed (hot) in dies (usually with two halves) such that the flow of metal from the die cavity is restricted. The excess material is extruded through a restrictive narrow gap and appears as flash around the forging at the die parting line.

Equipment. Anvil and counterblow hammers, hydraulic, mechanical, and screw presses.

Materials. Carbon and alloy steels, aluminum alloys, copper alloys, magnesium alloys, beryllium, stainless steels, nickel alloys, titanium and titanium alloys, iron and nickel and cobalt super alloys.

Process Variations. Closed-die forging with lateral flash, closed-die forging with longitudinal flash, closed-die forging without flash.

Application. Production of forgings for automobiles, trucks, tractors, off-highway equipment, aircraft, railroad and mining equipment, general mechanical industry, and energy-related engineering production.

Related Topics