Chapter: Mechanical : Engineering materials and metallurgy : Heat Treatment Process

Heat Treatment Process

HEAT TREATMENT PROCESS

1 Basic principles of heat treatment

2 Hardening

3 Annealing

4 Normalizing

5 Hardening process

6 Thermo chemical process

7.Tempering

8 Martempering and Austempering

1.BASIC PRINCIPLES OF HEAT

TREATMENT

Heat treatment of a metal or alloy is a

technological procedure, including controlled heating and cooling operations,

conducted for the purpose of changing the alloy microstructure and resulting in

achieving required properties.

There are

two general objectives of heat treatment: hardening and annealing.

2.HARDENING

Hardening is a process of increasing the metal

hardness, strength, toughness, fatigue resistance.

·

Strain hardening (work hardening) – strengthening

by cold work (cold deformation)

Cold

plastic deformation causes increase of concentration of dislocations, which

mutually entangle one another, making further dislocation motion difficult and

therefore resisting the deformation or increasing the metal strength.

·

Grain size strengthening (hardening) -

strengthening by grain refining.

Grain

boundaries serve as barriers to dislocations, raising the stress required to

cause plastic deformation.

• Solid

solution hardening- strengthening by dissolving an alloying element.

Atoms of

solute element distort the crystal lattice, resisting the dislocations motion.

Interstitial elements are more effective in solid solution hardening, than

substitution elements.

•

Dispersion strengthening – strengthening by adding second phase into metal

matrix.

The

second phase boundaries resist the dislocations motions, increasing the

material strength. The strengthening effect may be significant if fine hard

particles are added to a soft ductile matrix (composite materials).

Hardening

by result of Spinodal decomposition. Spinodal structure is characterized by

strains on the coherent boundaries between the Spinodal phases causing

hardening of the alloy.

•

Precipitation hardening (age hardening) - strengthening by precipitation of

fine particles of a second phase from a supersaturated solid solution.

The

second phase boundaries resist the dislocations motions, increasing the

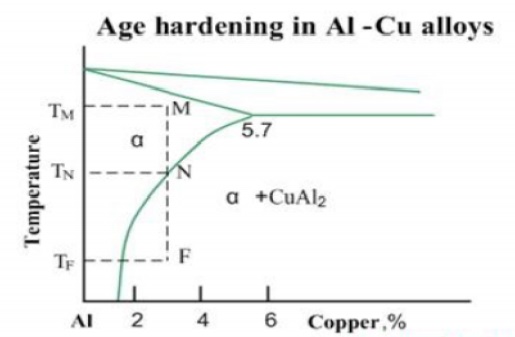

material strength. The age hardening mechanism in Al-Cu alloys may be

illustrated by the phase diagram of Al-Cu system. When an alloy Al-3%Cu is

heated up to the temperature TM, all CuAl2 particles are dissolved and the

alloy exists in form of single phase solid solution (α-phase). This operation

is called solution treatment.

Slow

cooling of the alloy will cause formation of relatively coarse particles of

CuAl2 intermetallic phase, starting from the temperature TN.However if the the

cooling rate is high (quenching), solid solution will retain even at room

temperature TF. Solid solution in this non-equilibrium state is called

supersaturated solid solution.

Obtaining

of supersaturated solid solution is possible when cooling is considerably

faster, than diffusion processes. As the diffusion coefficient is strongly

dependent on the the precipitation of CuAl2 from supersaturated temperature,

solution is much faster at elevated temperatures (lower than TN).This process

is called artificial aging. It takes usually a time from several hours to one

day. When the aging is conducted at the room temperature, it is called natural

aging. Natural aging takes several days or more.

Precipitation

from supersaturate d solid solution occurred in several steps:

·

Segregation of Cu atoms into plane clusters. These

clusters are called called Guinier-Preston1 zones (G-P1 zones).

· Diffusion of Cu atoms to the G -P1 zones and

formation larger clusters, called GP2 zones or θ” phase. This phase is coherent

with the matrix .

·

Formation of ‘θ’ phase which is partially coherent

with the matrix. This phase provides maximum hardening.

3.ANNEALING

Annealing

is a heat treatment procedure involving heating the alloy and holding it at a

certain temperature (annealin g temperature), followed by controlled cooling.

Annealing

results in relief of internal stresses, softening, chemical homogenizing and

transformation of the grain structure into more stable state.

Annealing stages:

Stress Relif - a relatively low temperatu re

process of reducing internal mechanical stresses, caused by cold-work, casting

or welding.

During this process atoms move to more stable

positions in the crystal lattice. Vacancies and interstitial defects are

eliminated and some dislocations are annihilate d.

Recovery

heat treatment is used mainly for preventing stress-corrosion cracking and decreasing

distortions, caused by internal stresses.

Recrystallation

-alteration of the grain structure of the metal.

If the

alloy reaches a par ticular temperature (recrystallization or annealing

temperature) new grains start to grow from the nuclei formed in the cold worked

metal. The new grains absorb imperfections an d distortions caused by cold

deformation. The grains are equi-axed and independent to the ol d grain

structure.

As a result of recrystallization mechanical

properties (stre ngth, ductility) of the alloy return to the pre-cold-work

level. The annealing te mperature and the new grains size are dependent on the

degree of cold-wor k which has been conducted. The more the cold-work degree,

the lower the annealing temperature and the fine recrystallization grain

structure. Low d egrees of cold-work (less than 5%) may cause formation of

large grains.Usually the annealing temperature of metals is between one-third

to one-half of t he freezing point measured in Kelvin (absolute) tem perature

scale.

Grains

Growth: (ov er-annealing, secondary recrystallization) - growth of the new

grains at the expense of their neighbors, occurring at temperature, above the

recrystallization temperat ure.

This

process results in coarsening grain structure and is undesirable.

THE SOFTENING PROCESSES

Heat Treatment is the controlled heating and

cooling of metals to alter their physical and mechanical properties without

changing the product shape. Heat treatment is sometimes done inadvertently due

to manufacturing processes that either heat or cool the metal such as welding

or forming. Heat Treatment is often associated with increasing the strength of

material, but it can also be used to alter certain manufacturability objectives

such as improve machining, improve formability, restore ductility after a cold

working operation. Thus it is a very enabling manufacturing process that can

not only help other manufacturing process, but can also improve product

performance by increasing strength or other desirable characteristics. Steels

are particularly suitable for heat treatment, since they respond well to heat

treatment and the commercial use of steels exceeds that of any other material.

Steels are heat treated for one of the following reasons:

Softening

Softening

is done to reduce strength or hardness, remove residual stresses, improve

toughnesss, restore ductility, refine grain size or change the electromagnetic

properties of the steel.

Restoring

ductility or removing residual stresses is a necessary operation when a large

amount of cold working is to be performed, such as in a cold- rolling operation

or wiredrawing.

Annealing

— full Process, spheroidizing, normalizing and tempering— austempering,

martempering are the principal ways by which steel is softened.

Hardening:

Hardening

of steels is done to increase the strength and wear properties. One of the

pre-requisites for hardening is sufficient carbon and alloy content. If there

is sufficient Carbon content then the steel can be directly hardened. Otherwise

the surface of the part has to be Carbon enriched using some diffusion

treatment hardening techniques. Material Modification: Heat treatment is used

to modify properties of materials in addition to hardening and softening. These

processes modify the behavior of the steels in a beneficial manner to maximize

service life, e.g., stress relieving, or strength properties, e.g., cryogenic

treatment, or some other desirable properties, e.g., spring aging.

Annealing

Used

variously to soften, relieve internal stresses, improve machinability and to

develop particular mechanical and physical properties.In special silicon steels

used for transformer laminations annealing develops the particular

microstructure that confers the unique electrical properties.Annealing requires

heating to above the As temperature, holding for sufficient time for

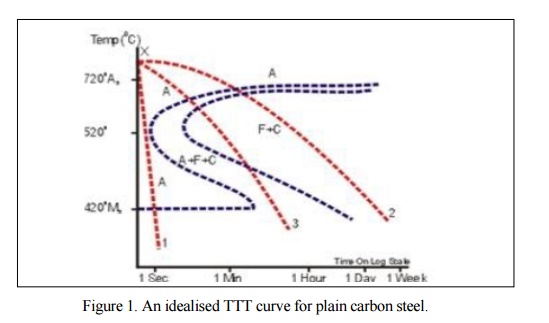

temperature equalisation followed by slow cooling. See Curve 2 in Figure.1

Stress

from the forming operations can affect both rimfire and centerfire cartridge

cases. For many cases, especially those with bottlenecks, the stresses are so

great that high-temperature annealing must be used.After forming, a bottleneck

case may appear perfectly serviceable. However, massive stresses are likely to

remain in these areas. If the ammunition is loaded and stored without

addressing these stresses, cracks can appear in the bottleneck area.

Case bottlenecks are normally flame-annealed by the

following process:

Case

bottlenecks are normally flame-annealed by the following process:

Placed on

a moving rail or rotary disk system, the case passes before a set of gas

burners that rapidly heat the neck and shoulder area to glowing.

As the

becomes incandescent the brass grains grow larger. he heated area of the case

is immediately tipped into a water bath to quench the case, establishing the

large grain size.

The

treatment causes a dark, but harmless, discoloration to the neck area. In

commercial ammunition, this dark area may be polished out for cosmetic reasons;

in U.S. military ammunition, the discoloration remains vi sible.

The

application of heat treatment technology to vary the grain size gradually, from

small grains in the head area to large o nes at the case mouth, determines c

ase hardness. All high pressure cases must have variable metallurgical

properties depending on the part of the case, as follows:

Head - must be t ough and relatively

unyielding, small brass grains contribute to the t oughness.

4.NORMALISING

Also used

to soften and relieve internal stresses after cold work and to refine the grain

size and m etallurgical structure. It may be used t o break up the dendritic

(as cast) str ucture of castings to improve their m achinability and future

heat treatment response or to mitigate banding in rolled steel. This requires

heatin g to above the As temperature, holding for sufficient time to allow tem

perature equalization followed by air co oling. It is therefore similar to

annealing but with a faster cooling rate. Curve 3 in Figure I would give a

normalized structure.

5.THE HARDENING PRO CESSES

Hardening

In this

process steels which contain sufficient carbon, and perhaps other alloying

elements, are cooled (quenc hed) sufficiently rapidly from above the

transformation temperature to produce Martensite, the hard phase already

described, s ee Curve 1 in Figure 1.There is a range of quenching media of

varying severity, water o r brine being the most severe, through oil and

synthetic products to air which is the least severe.

Tempering

After

quenching the steel is hard, brittle and internally stre ssed. Before use, it

is usually necessar y to reduce these stresses and increa se toughness by

'tempering'. There will als o be a reduction in hardness and the selection of

tempering temperature dictates The final properties. Tempering curves, which

are plots of hardness against tempering temperature. exist for all commercial

steels and are used to select the correct tempering temperature. As a rule of

thumb, within the tempering range for a particular steel, the higher the

tempering temperature the lower the final hardness but the greater the

toughness. It should be noted that not all steels will respond to all heat

treatment processes, Table 1 summaries the response, or otherwise, to the

different processes.

Boronised

substrates will often require heat treatment to restore mechanical properties.

As borides degrade in atmospheres which contain oxygen, even when combined as

CO or C02, they must be heat treated in vacuum, nitrogen or nitrogen/hydrogen

atmospheres.

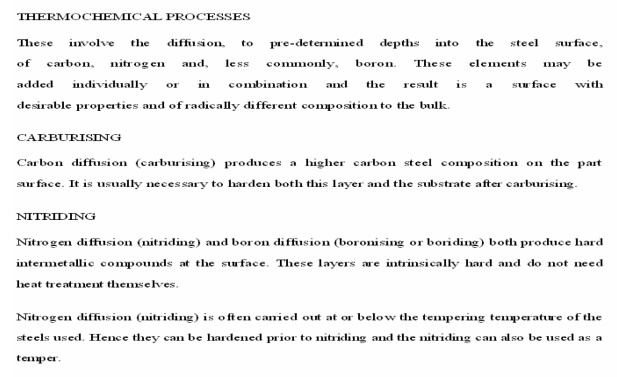

PROCESSING METHODS

In the past the thermochemical processes were

carried out by pack cementation or salt bath processes. These are now largely

replaced, on product quality and environmental grounds, by gas and plasma

techniques. The exception is boronising, for which a safe production scale

gaseous route has yet to be developed and pack cementation is likely to remain

the only viable route for the for some time to come.

The gas processes are usually carried out in the

now almost universal seal quench furnace, and any subsequent heat treatment is

readily carried out immediately without taking the work out of the furnace.

This reduced handling is a cost and quality benefit.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

TECHNIQUES AND PRACTICE

As we

have already seen this requires heating to above the As temperature, holding to

equalise the temperature and then slow cooling. If this is done in air there is

a real risk of damage to the part by decarburisation and of course oxidation.

It is increasingly common to avoid this by ‗bright„ or ‗close„ annealing using

protective atmospheres. The particular atmosphere chosen will depend upon the

type of steel.

NORMALISING

In common

with annealing there is a risk of surface degradation but as air cooling is

common practice this process is most often used as an intermediate stage to be

followed by machining, acid pickling or cold working to restore surface

integrity.

HARDENING

With many

components, hardening is virtually the final process and great care must taken

to protect the surface from degradation and decarburisation. The ‗seal quench„

furnace is now an industry standard tool for carbon, low and medium alloy

steels. The work is protected at each stage by a specially generated

atmosphere.

Some tool

steels benefit from vacuum hardening and tempering; salt baths were widely used

but are now losing favour on environmental grounds.

7.TEMPERING

Tempering

is essential after most hardening operations to restore some toughness to the

structure. It is frequently performed as an integral part of the cycle in a

seal quench furnace, with the parts fully protected against oxidation and

decarburisation throughout the process. Generally tempering is conducted in the

temperature range 150 to 700°C, depending on the type of steel and is time

dependent as the microstructural changes occur relatively slowly.

Caution:

Tempering can,in some circumstances, m a k e the steel brittle which is the

opposite of what it is intended to achieve.

There are

two forms of this brittleness Temper

Brittleness which affects both carbon and low alloy steels when either,

they are cooled too slowly from above 575°C, or are held for excessive times in

the range 375 to 575°C. The embrittlement can be reversed by heating to above

575°C and rapidly cooling.

Blue Brittleness affects carbon and some alloy

steels after tempering in the range 230 to 370°C The effect is not reversible

and susceptible steels should not be employed in applications in which they

sustain shock loads. If there is any doubt consult with the heat treater or in

house metallurgical department about the suitability of the steel type and the

necessary heat treatment for any application.

8.MARTEMPERING AND AUSTEMPERING

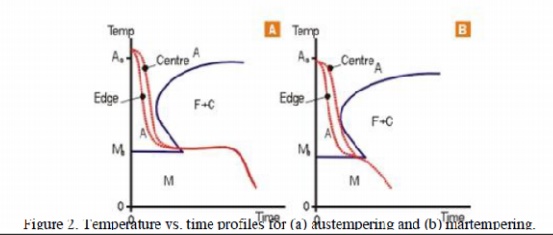

It will

be readily appreciated that the quenching operation used in hardening

introduces internal stresses into the steel. These can be sufficiently large to

distort or even crack the steel.

Martempering

is applied to steels of sufficient hardenability and involves an isothermal

hold in the quenching operation. This allows temperature equalisation across

the section of the part and more uniform cooling and structure, hence lower

stresses. The steel can then be tempered in the usual way.

Austempering

also invo lves an isothermal hold in the quenching operation, but the structure

formed, whilst hard and tough, does not require further tempering. The process

is mostly applied to high carbon steels in relatively thin sections for springs

o r similarparts . These processes are shown schematically in the TTT Curves,

(figures 2a and 2b). there is sufficient heat sink in the part and an external

quench is not needed. There is a much lower risk of distortion associated with

this practice, and it can be highly automated and it is very reproducible

Body -

the case walls must combine flexibility and strength to contribute to the

obturati on system.

Mouth -

must be softer (larger brass grains) to prevent cracks from the strain of

holding a bullet.

Related Topics