Chapter: Mechanical : Engineering materials and metallurgy : Ferrous and Non Ferrous Metals

Ferrous and Non Ferrous Metals

FERROUS AND NON FERROUS METALS

1 Effect of alloying elements on steel properties

2 Characteristics of alloying elements

3 Maraging steels

4 Heat treatment cycle

5 Classificaion of copper and its alloys

5.1 Brasses

5.2 Bronze

5.3 Tool and die steel

6 Effects of alloying elements on steel

1.EFFECT OF ALLOYING ELEMENTS ON

STEEL PROPERTIES

Alloying

is changing chemical composition of steel by adding elements with purpose to

improve its properties as compared to the plane carbon steel.

The properties, which may be

improved

Stabilizing austenite -

increasing the temperature range, in which austenite exists.

The

elements, having the same crystal structure as that of austenite (cubic face

centered - FCC), raise the A4 point (the temperature of formation of austenite

from liquid phase) and decrease the A3 temperature. These elements are nickel

(Ni), manganese (Mn), cobalt (Co) and c opper (Cu).

Examples

of austenitic steels: austenitic stainless steels, Hadfield steel (1%C, 13%Mn,

1.2%Cr).

Stabilizing ferrite -

decreasing the temperature range, in which austenite exists.

The

elements, having the same crystal structure as that of ferrite (cubic body

centered - BCC), lower the A4 point and increase the A3 temperature.

These

elements lower the solubility of carbon in austenite, causing increase of

amount of carbides in the steel.

The

following elements have ferrite stabilizing effect: chromium (Cr),

tungsten

(W), Molybdenum (Mo), vanadium (V), aluminum (Al) and silicon (Si).

Examples

of ferritic steels:transformer sheets steel (3%Si), F-Cr alloy

Carbide forming -

elements forming hard carbides in steels.

The

elements like chromium (Cr), tungsten (W), molybdenum (Mo),vanadium (V),

titanium (Ti), niobium (Nb), tantalum (Ta),zirconium (Zr) form hard (often

complex) carbides, increasing steel hardness and strength.Examples of steels

containing relatively high concentration of carbides: hot work tool steels,

high speed steels. Carbide forming elements also form nitrides reacting with

Nitrogen in steels.

Graphitizing -

decreasing stability of carbides, promoting their breaking and formation of

free Graphite.

The

following elements have graphitizing effect: silicon (Si), nickel (Ni), cobalt

(Co), aluminum (Al).

Decrease of the eutectoid concentration.

The

following elements lower eutectoid concentration of carbon:

titanium

(Ti), molybdenum (Mo), tungsten (W), silicon (Si), chromium (Cr), nickel (Ni).

Increase of corrosion resistance.

Aluminum

(Al), silicon (Si), and chromium (Cr) form thin an strong oxide film on the

steel surface, protecting it from chemical attacks.

2.CHARACTERISTICS OF ALLOYING

ELEMENTS

Manganese

(Mn) - improves hardenability, ductility and wear resistance. Mn eliminates

formation of harmful iron sulfides, increasing strength at high temperatures.

Nickel

(Ni) - increases strength, impact strength and toughness, impart corrosion

resistance in combination with other elements.

Chromium

(Cr) - improves hardenability, strength and wear resistance, sharply increases

corrosion resistance at high concentrations (> 12%).

Tungsten

(W) - increases hardness particularly at elevated due to temperatures stable

carbides, refines grain size.

Vanadium

(V) - increases strength, hardness, creep resistance and impact resistance due

to formation of hard vanadium carbides, limits grain size.

Molybdenum

(Mo) - increases hardenability and strength particularly at high temperatures

and under dynamic conditions.

Silicon

(Si) - improves strength, elasticity, acid resistance and promotes large grain

sizes, which cause increasing magnetic permeability.

Titanium

(Ti) - improves strength and corrosion resistance, limits austenite grain size.

Cobalt

(Co) - improves strength at high temperatures and magnetic permeability.

Zirconium

(Zr) - increases strength and limits grain sizes.

Boron

(B) - highly effective hardenability agent, improves deformability and

machinability.

Copper

(Cu) - improves corrosion resistance.

Aluminum

(Al) - deoxidizer, limits austenite grains growth.

3.MARAGING STEELS

Maraging

steels (from martensitic and aging) are steels (iron alloys) which are known

for possessing superior strength and toughness without losing malleability,

although they cannot hold a good cutting edge. Aging refers to the extended

heat-treatment process. These steels are a special class of low- carbon ultra-

high-strength steels which derive their strength not from carbon, but from

precipitation of inter-metallic compounds. The principal alloying element is 15

to 25% nickel. Secondary alloying elements are added to produce intermetallic

precipitates, which include cobalt, molybdenum, and titanium. Original

development was carried out on 20 and 25% Ni steels to which small additions of

Al, Ti, and Nb were made.

The

common, non-stainless grades contain 17-19% nickel, 8-12% cobalt,3-5%

molybdenum, 0.2-1.6% titanium. Addition of chromium and produces stainless

grades resistant to corrosion. This also indirectly increases hardenability as

they require less nickel: high-chromium, high-nickel steels are generally

austenitic and unable to transform to martensite when heat treated, while

lower-nickel steels can transform to martensite.

Properties

Due

to the low carbon content maraging steels have good machinability. Prior t o aging,

they may also be cold rolled to as much as 80- 90% without cracking. Maraging

steels offer good weldability, but must be aged afterward to restore the

properties of heat affected zone. When heat-treated the alloy has very little

dimensional change, so it is often machined to its final dimensions. Due to the

high alloy content maraging steels have a high hardenability. Since ductile

FeNi martensites are formed upon cooling, cracks are non-existent or

negligible. The steels can be nitrided to increase case hardness, and polished

to a fine surface finish.

Non-stainless

varieties of maraging steel are moderately corrosion- resistant, and resist

stress corrosion and hydrogen embrittlement. Corrosion- resistance can be

increased by cadmium plating or phosphating.

4.HEAT TREATMENT CYCLE

The

steel is first annealed at approximately 820 °C (1,510 °F) for 15- 30 minutes

for thin sections and for 1 hour per 25 mm thickness for heavy sections, to

ensure formation of a fully austenitized structure. This is followed by air

cooling to room temperature to form a soft, heavily-dislocated iron-nickel lath

(untwinned) martensite. Subsequent aging (precipitation hardening) of the more

common alloys for approximately 3 hours at a temperature of 480 to 500 °C

produces a fine dispersion of Ni3(X,Y) intermetallic phases along dislocations

left by martensitic transformation, where X and Y are solute elements added for

such precipitation. Overaging leads to a reduction in stability of the primary,

metastable, coherent precipitates, leading to their dissolution and replacement

with semi-coherent Laves phases such as Fe2Ni/Fe2Mo. Further excessive heat-

treatment brings about the decomposition of the martensite and reversion to

austenite.

Newer

compositions of maraging steels have revealed other intermetallic

stoichiometries and crystallographic relationships with the parent martensite,

including rhombohedral and massive complex Ni50(X,Y,Z)50 (Ni50M50 in simplified

notation).

Uses

Maraging

steel's strength and malleability in the pre-aged stage allows it to be formed

into thinner rocket and missile skins than other steels, reducing weight for a

given strength. Maraging steels have very stable properties, and, even after

overaging due to excessive temperature, only soften slightly. These alloys

retain their properties at mildly elevated operating temperatures and have

maximum service temperatures of over 400 °C (752 °F)

They

are suitable for engine components, such as crankshafts and gears, and the

firing pins of automatic weapons that cycle from hot to cool repeatedly while

under substantial load. Their uniform expansion and easy machinability before

aging make maraging steel useful in high-wear

components

of assembly lines and dies. Other ultra-high-strength steels, such as Aermet

alloys, are not as machinable because of their carbide content.

In the sport of fencing, blades used in

competitions run under the auspices of the Fédération Internationale d'Escrime

are often made with maraging steel. Maraging blades are required in foil and

épée because crack propagation in maraging steel is 10 times slower than in

carbon steel, resulting in less blade breakage and fewer injuries. The notion

that such blades break flat is a fencing urban legend: testing has shown that

the blade-breakage patterns in carbon steel and maraging steel blades are

identical.

Stainless maraging steel is used in bicycle

frames and golf club heads. It is also used in surgical components and

hypodermic syringes, but is not suitable for scalpel blades because the lack of

carbon prevents it from holding a good cutting edge. Maraging steel production,

import, and export by certain states, such as the

United

States, is closely monitored by international authorities because it is

particularly suited for use in gas centrifuges for uranium enrichment; lack of

maraging steel significantly hampers this process. Older centrifuges used

aluminum tubes; modern ones, carbon fiber composite.

Copper alloys

are metal alloys that have copper as their principal component. They have high

resistance against corrosion. The best known traditional types are bronze,

where tin is a significant addition, and brass, using zinc instead. Both these

are imprecise terms, and today the term copper alloy tends to be substituted,

especially by museums.

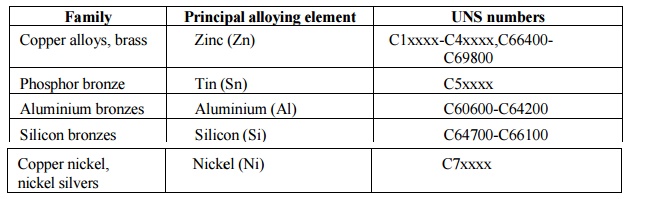

Compositions

The similarity in external appearance of the

various alloys, along with the different combinations of elements used when

making each alloy, can lead to confusion when categorizing the different

compositions. There are as many as 400 different copper and copper-alloy

compositions loosely grouped into the categories: copper, high copper alloy,

brasses, bronzes, copper nickels, copper-nickel-zinc (nickel silver), leaded

copper, and special alloys. The following table lists the principal alloying

element for four of the more common types used in modern industry, along with

the name for each type. Historical types, such as those that characterize the

Bronze Age, are vaguer as the mixtures were generally variable.

5.CLASSIFICATION OF COPPER AND ITS

ALLOYS

1.BRASSES

A brass is an alloy of copper with zinc.

Brasses are usu ally yellow in color. The zinc content can vary between few %

to about 40%; as long as it is kept under 15%, it does not markedly decrease

corrosion resistance of copper. Brasses can be se nsitive to selective leaching

corrosion under certain conditions, when zinc is leached from the alloy

(dezincification), leaving behind a spongy copper structure.

2.BRONZES

A bronze is an alloy of copper and other

metals, most often tin, but also aluminium and silicon.

Aluminium bronzes are alloys of copper and

aluminium. The content of aluminium ranges mostly between 5-11%. Iron, nickel,

manganes e and silicon are sometimes added. Th ey have higher strength and

corrosion resistance than other bronzes, especially in m arine environment, and

have low reactivity to sulfur compounds. Aluminium forms a thin passivation

layer on the surface of the metal.

CARBON STEELS

Carbon steels are iron-carbon alloys

containing up to 2.06% of carbon, up to 1.65% of manganese, up to 0.5% of

silicon and sulfur and phosphorus as impurities. Carbon content in carbon steel

determines its strength and ductility. The higher carbon content, the higher steel

strength and the lower its ductility.

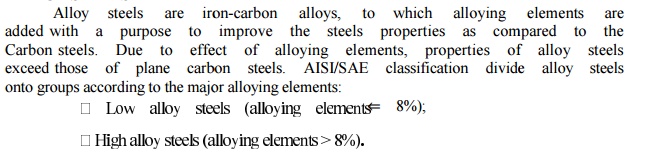

ALLOY STEELS

Alloy steels are ir on-carbon alloys, to which

alloying elements are added with a purpose to improve the steels properties as

com pared to the Carbon steels. Due to effect of alloying elements, properties

of alloy steels exceed those of plane carbon steels. AISI/SAE classification

divide alloy steels

According

to the four-digit classification SAE/AISI system: First digit indicates the

class of the alloy steel:

2-

Nickel steels;

3-Nickel-chromiu

m steels;

4-

Molybdenum steels;

5-

Chromium steels;

6-Chromium-vanadium

steels;

7-Tungsten-chrom

ium steels;

9-

Silicon-manganese steels.

Second

digit indicates concentration of the major element in percents (1 means 1%).

Last

two digits indicate carbon concentration in 0,01%.

Example:

SAE 5130 means alloy chromium steel, containing 1% of chromium and 0.30% of

carbon.

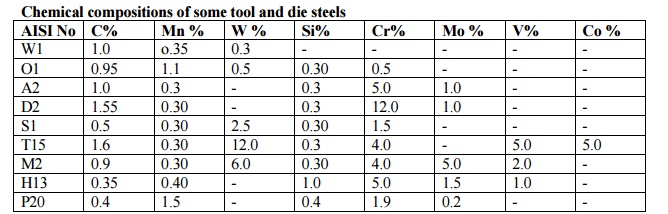

3.TOOL AND DIE STEELS

Tool

and die steels are high carbon steels (either carbon or alloy) possessing high

hardness, strength and wear resistance. Tool steels are heat treatable. In

order to increase hardness and wear resistance of tool steels, alloying

elements forming hard and stable carbides (chromium, tungsten, vanadium,

manganese, molybdenum) are added to the composition. Designation system of

one-letter in combination with a number is accepted for tool steels. The letter

means:W - Water hardened plain carbon tool steels

Applications:

chisels, forging dies, hummers, drills, cutters, shear blades, cutters, drills,

razors.

Properties:

low cost, very hard, brittle, relatively low harden ability, suitable for small

parts working at not elevated temperatures.

O,

A, D - Cold work tool steels

Applications:

drawing and forging dies, shear blades, highly effective cutters. Properties:

strong, hard and tough crack resistant.

O

-Oil hardening cold work alloy steels;

A

-Air hardening cold work alloy steels;

D

-Diffused hardening cold work alloy steels;

S

- Shock resistant low carbon tool steels

Applications:

tools experiencing hot or cold impact.

Properties:

combine high toughness with good wear resistance.

T,M

– High speed tool steels (T-tungsten, M-molybdenum)

Applications:

cutting tools. Properties: high wear heat and shock resistance.

H

– Hot work tool steels

Applications:

parts working at elevated temperatures, like extrusion, casting and forging

dies. Properties: strong and hard at elevated temperatures.

P

- Plastic mold tool steels

Applications:

molds for injection molding of plastics.

Properties:

good machinability.

Chemical compositions of some tool and die steels

6.EFFECTS OF ALLOYING ELEMENTS IN

STEEL

Steel

is basically iron alloyed to carbon with certain additional elements to give

the required properties to the finished melt. Listed below is a summary of the

effects various alloying elements in steel.

Carbon

The

basic metal, iron, is alloyed with carbon to make steel and has the effect of

increasing the hardness and strength by heat treatment but the addition of

carbon enables a wide range of hardness and strength.

Manganese

Manganese

is added to steel to improve hot working properties and increase strength,

toughness and hardenability. Manganese, like nickel, is an austenite forming

element and has been used as a substitute for nickel in the A.I.S.I 200 Series

of Austenitic stainless steels (e.g. A.I.S.I 202 as a substitute for A.I.S.I

304)

Chromium

Chromium is added to the steel to increase

resistance to oxidation. This resistance increases as more chromium is added. 'Stainless

Steel' has approximately 11% chromium and a very marked degree of general

corrosion resistance when compared with steels with a lower percentage of

chromium. When added to low alloy steels, chromium can increase the response to

heat treatment, thus improving hardenability and strength.

Nickel

Nickel

is added in large amounts, over about 8%, to high chromium stainless steel to

form the most important class of corrosion and heat resistant steels. These are

the austenitic stainless steels, typified by 18-8, where the tendency of nickel

to form austenite is responsible for a great toughness and high strength at

both high and low temperatures. Nickel also improves resistance to oxidation

and corrosion. It increases toughness at low temperatures when added in smaller

amounts to alloy steels.

Molybdenum

Molybdenum,

when added to chromium-nickel austenitic steels, improves resistance to pitting

corrosion especially by chlorides and sulphur chemicals. When added to low

alloy steels, molybdenum improves high temperature strengths and hardness. When

added to chromium steels it greatly diminishes the tendency of steels to decay

in service or in heat treatment.

Titanium

The

main use of titanium as an alloying element in steel is for carbide

stabilisation. It combines with carbon to for titanium carbides, which are

quite stable and hard to dissolve in steel, this tends to minimise the

occurrence of inter-granular corrosion, as with A.I.S.I 321, when adding

approximately 0.25%/0.60% titanium, the carbon combines with the titanium in

preference to chromium, preventing a tie -up of corrosion resisting chromium as

inter-granular carbides and the accompanying loss of corrosion resistance at

the grain boundaries.

Phosphorus

Phosphorus

is usually added with sulphur to improve machinability in low alloy steels,

phosphorus, in small amounts, aids strength and corrosion resistance.

Experimental work shows that phosphorus present in austenitic stainless steels

increases strength. Phosphorus additions are known to increase the tendency to

cracking during welding.

Sulphur

When

added in small amounts sulphur improves machinability but does not cause hot

shortness. Hot shortness is reduced by the addition of manganese, which

combines with the sulphur to form manganese sulphide. As manganese sulphide has

a higher melting point than iron sulphide, which would form if manganese were

not present, the weak spots at the grain boundaries are greatly reduced during

hot working.

Selenium

Selenium

is added to improve machinability.

Niobium (Columbium)

Niobium

is added to steel in order to stabilise carbon, and as such performs in the

same way as described for titanium. Niobium also has the effect of

strengthening steels and alloys for high temperature service.

Nitrogen

Nitrogen

has the effect of increasing the austenitic stability of stainless steels and

is, as in the case of nickel, an austenite forming element. Yield strength is

greatly improved when nitrogen is added to austenitic stainless steels.

Silicon

Silicon

is used as a deoxidising (killing) agent in the melting of steel, as a result,

most steels contain a small percentage of silicon. Silicon contributes to

hardening of the ferritic phase in steels and for this reason silicon killed

steels are somewhat harder and stiffer than aluminium killed steels.

Cobalt

Cobalt

becomes highly radioactive when exposed to the intense radiation of nuclear

reactors, and as a result, any stainless steel that is in nuclear service will

have a cobalt restriction, usually aproximately 0.2% maximum. This problem is

emphasised because there is residual cobalt content in the nickel used in

producing these steels.

Tantalum

Chemically

similar to niobium and has similar effects.

Copper

Copper

is normally present in stainless steels as a residual element. However it is

added to a few alloys to produce precipitation hardening properties.

Related Topics