Chapter: Mechanical : Engineering materials and metallurgy : Constitution of Alloys and Phase Diagrams

Constitution of Alloys and Phase Diagrams

CONSTITUTION OF ALLOYS AND PHASE

DIAGRAMS

1 Classification of materials

2 Type of bonding

3 Crystal structures

4 Imperfection in solids

5 Introduction to phase diagram

6 Solid solution

7 Iron Carbon Diagram

8 Metal types

8.1 Ferrous metals

8.2 Alloy steels

8.3 Non ferrous metals

1 CLASSIFICATION OF MATERIALS

1Metals

Valence electrons are detached from

atoms, and spread in an 'electron

sea' that "glues" the ions together. Metals are usually strong,

conduct electricity and heat well and are opaque to light (shiny if polished).

Examples: aluminum, steel, brass, gold.

2 Semiconductors

The bonding is covalent (electrons are shared

between atoms). Their electrical properties depend extremely strongly on minute

proportions of contaminants. They are opaque to visible light but transparent

to the infrared. Examples: Si, Ge, GaAs.

3Ceramics

Atoms behave mostly like either positive or

negative ions, and are bound by Coulomb forces between them. They are usually

combinations of metals or semiconductors with oxygen, nitrogen or carbon

(oxides, nitrides, and carbides). Examples: glass, porcelain, many minerals.

4.Polymers

Are bound

by covalent forces and also by weak van

der Waals forces, and usually based on H, C and other non-metallic elements. They

decompose at moderate

temperatures (100 - 400 C), and are lightweight. Other

properties vary greatly. Examples: plastics (nylon, Teflon, polyester)

and rubber.

2 TYPES OF BONDING

1 Ionic Bonding

This is the bond when one of the atoms is negative

(has an extra electron) and another is positive (has lost an electron). Then

there is a strong, direct Coulomb attraction. An example is NaCl. In the

molecule, there are more electrons around Cl, forming Cl- and less

around Na, forming Na+. Ionic bonds are the strongest bonds.

1.2.2 Covalent

Bonding

In

covalent bonding, electrons are shared between the molecules, to saturate the valency. The

simplest example is the H2

molecule, where the electrons spend

more time in between the nuclei than outside, thus producing bonding.

3 Metallic Bonding

In the

metallic bond encountered in pure metals and metallic alloys, the atoms

contribute their outer-shell electrons to a generally shared electron cloud for

the whole block of metal.

Ø Secondary

Bonding (Van der Waals)

Ø Fluctuating

Induced Dipole Bonds Polar

Ø Molecule-Induced

Dipole Bonds

Ø Permanent

Dipole Bonds

3 CRYSTAL STRUCTURES

Atoms

self-organize in crystals, most of

the time. The crystalline lattice is a periodic array of the atoms. When the

solid is not crystalline, it is called amorphous. Examples of crystalline

solids are metals, diamond and other precious stones, ice, graphite. Examples

of amorphous solids are glass, amorphous carbon (a-C), amorphous Si, most

plastics

1.Unit Cells

The unit

cell is the smallest structure

that repeats itself by

translation through the crystal. The most common types of unit cells are

the faced centered cubic (FCC), the body-centered cubic (FCC) and the hexagonal

close-packed (HCP). Other types exist, particularly among minerals.

2.Polymorphism and Allotropy

Some

materials may exist in more than one crystal structure, this is called

polymorphism.

If the

material is an elemental solid, it is called allotropy. An example of allotropy

is carbon, which can exist as diamond, graphite, and amorphous carbon.

3.Polycrystalline Materials

A solid

can be composed of many crystalline grains, not aligned with each other. It is

called polycrystalline. The grains

can be more or less aligned with respect to each other. Where they meet is called a grain boundary.

4 IMPERFECTION IN SOLIDS

Materials

are not stronger when they have defects.

The study

of defects is divided according to their dimension:

0D (zero

dimension) - point defects: vacancies and interstitials Impurities. 1D - linear

defects: dislocations (edge, screw, mixed)

2D -

grain boundaries, surfaces. 3D - extended defects: pores, cracks

5 Introduction to phase diagram

Component

Pure

metal or compound (e.g., Cu, Zn in Cu-Zn alloy, sugar, water, in syrup.)

Solvent

Host or

major component in solution.

Solute

Dissolved,

minor component in solution.

System

Set of

possible alloys from same component (e.g., iron-carbon system.)

Solubility Limit

Maximum solute concentration that can be dissolved

at a given temperature.

Phase

Part with

homogeneous physical and chemical characteristics

6 Solid Solutions

A solid solution occurs when we alloy two metals

and they are completely soluble in each other. If a solid solution alloy is

viewed under a microscope only one type of crystal can be seen just like a pure

metal. Solid solution alloys have similar properties to pure metals but with

greater strength but are not as good as electrical conductors.

The common types of solid

solutions are

1) Substitutional

solid solution

2) Interstitial

solid solutions

Substitution solid solution

The name of this solid solution tells you exactly

what happens as atoms of the parent metal ( or solvent metal) are replaced or

substituted by atoms of the alloying metal (solute metal) In this case, the

atoms of the two metals in the alloy, are of similar size.

Interstitial solid solutions:

In interstitial solid solutions the atoms of the

parent or solvent metal are bigger than the atoms of the alloying or solute

metal. In this case, the smaller atoms fit into interstices i.e spaces between

the larger atoms.

Phases

One-phase systems are homogeneous. Systems with two

or more phases are heterogeneous, or mixtures. This is the case of most

metallic alloys, but also happens in ceramics and polymers.

A

two-component alloy is called binary. One with three components is called

ternary.

Microstructure

The properties of an alloy do not depend only on

concentration of the phases but how they are arranged structurally at the

microscopy level. Thus, the microstructure is specified by the number of

phases, their proportions, and their arrangement in space.

A binary

alloy may be

ØA single solid solution

ØTwo separated essentially pure

components. ØTwo separated solid solutions.

ØA chemical compound, together

with a solid solution.

Phase diagram:

A graph showing the phase or phases present for a

given composition as a function of temperature.

Poly phase material:

A

material in which two or more phases are present.

Eutectoid:

Transforming

from a solid phase to two other solid phases upon cooling.

Peritectoid:

Transforming

from two solid phases to a third solid phase upon cooling.

Peritectoid reaction:

A reaction in which a solid goes to a new solid

plus a liquid on heating, and reverse occurs on cooling.

Iron-Iron Carbon diagram is essential to understand

the basic differences among iron alloys and control of properties.

Iron is allotropic; at room temperature pure iron

exists in the Body Centered Cubic crystal form but on heating transforms to a

Face Centered Cubic crystal. The temperature that this first transformation

takes place is known as a critical point and it occurs at 910 degrees Celsius.

This change in crystal structure is accompanied by shrinkage in volume, sine

the atoms in the face centered crystal are more densely packed together than in

the body centered cubic crystal. At the second critical point the F.C.C crystal

changes back to a B.C.C crystal and this change occurs at 1390 degrees Celsius.

§ Iron

above 1390 degrees is known as delta iron

§ Iron

between 1390 and 910 degrees is known as gamma iron, Iron below 910 degrees is

known as alpha iron.

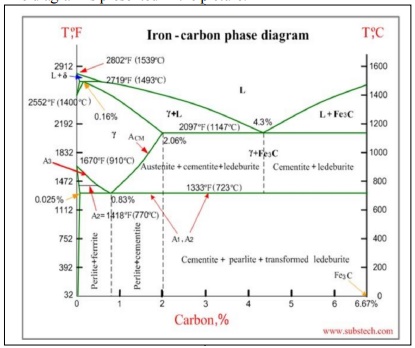

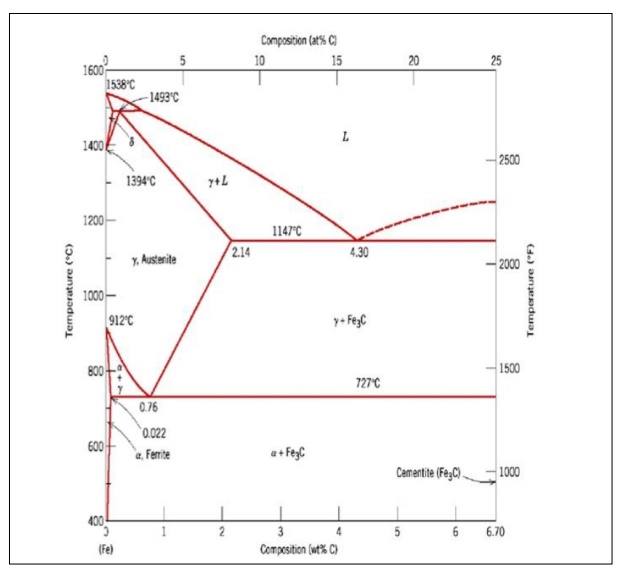

7 IRON CARBON DIAGRAM

Iron-carbon phase diagram

Iron-carbon

phase diagram describes the iron-carbon system of alloys containing up to 6.67%

of carbon, discloses the phases

compositions and their transformations occurring with the alloys during their cooling or heating. Carbon content 6.67% corresponds to the fixed c omposition of the iron carbide Fe3C.

The

diagram is presented in the picture:

The

following phases are involved in the transformation, occurring with iron-carbon

alloys: L - Liquid solution of carbon in iron;

δ-ferrite - Solid solution of carbon in iron.

Maximum concentration of carbon in δ-ferrite

is 0.09% at 2719 ºF (1493ºC) - temperature of the peritectic transformation.

The crystal structure of δ-ferrite is BCC

(cubic body centered). Austenite - interstitial solid solution of carbon in

γ-iron.

Austenite has FCC (cubic face centered)

crystal structure, permitting high solubility of carbon - up to 2.06% at 2097

ºF (1147 ºC).

Austenite

does not exist below 1333 ºF (723ºC) and maximum carbo n concentration at this

temperature is 0.83%.

α-ferrite

- solid solution o f carbon in α-iron. α-ferrite has BCC crystal structure and

low solubility of carbon - up to 0.25% at 1333 ºF (723ºC). α-ferrite exists at

room temperature.

Cementite

- iron carbide , intermetallic compound, having fixed com position Fe3C.

Cementite

is a hard and brittle substance, influencing on the properties of steels and cast

irons.

The

following phase transformations occur with iron-carbon alloys:

Alloys,

containing up to 0.51% of carbon, start soli dification with formation of

crystals of δ-ferrite. Carbon content in δ-ferrite increases up to 0.09% in

course solidification, and at 2719 ºF (1493ºC) remaining liquid phase and δ-

ferrite perform peritectic transformation, resulting in formation of austenite.

Alloys,

containing carbon more than 0.51%, but less than 2.06%, form primary austenite

crystals in the beginning of solidification and when the temperature reaches

the curve ACM primary cementite stars to form.

Iron-carbon

alloys, containing up to 2.06% of carbon, are called steels.

Alloys,

containing from 2.06 to 6.67% of carbon,

experience eutectic transformation at 2097 ºF (1147 ºC). The eutectic

concentration of carbon is 4.3%.

In

practice only hypoeutectic alloys are used. These alloys (carbon content from

2.06% to 4.3%) are called cast irons. When

temperature of an alloy from

this range reaches 2097 ºF (1147

ºC), it contains

primary austenite crystals and

some amount of

the liquid phase. The latter decomposes by eutectic mechanism to a fine mixture of

austenite and cementite, called ledeburite.

All

iron-carbon alloys (steels and cast irons) experience eutectoid transformation

at 1333 ºF (723ºC). The eutectoid concentration of carbon is 0.83%.

When the

temperature of an alloy reaches 1333 ºF (733ºC), austenite transforms to pearlite

(fine ferrite-cementite structure,

forming as a result

of decomposition of austenite at slow cooling conditions).

Critical temperatures

Upper

critical temperature (point) A3 is the temperature, below which ferrite starts

to form as a result of ejection from austenite in the hypoeutectoid alloys.

Upper

critical temperature (point) ACM is the temperature, below which cementite

starts to form as a result of ejection from austenite in the hypereutectoid

alloys.

Lower

critical temperature (point) A1 is the temperature of the austeniteto-pearlite

eutectoid transformation. Below this temperature austenite does not exist.

Magnetic

transformation temperature A2 is the temperature below which α-ferrite is

ferromagnetic.

Phase

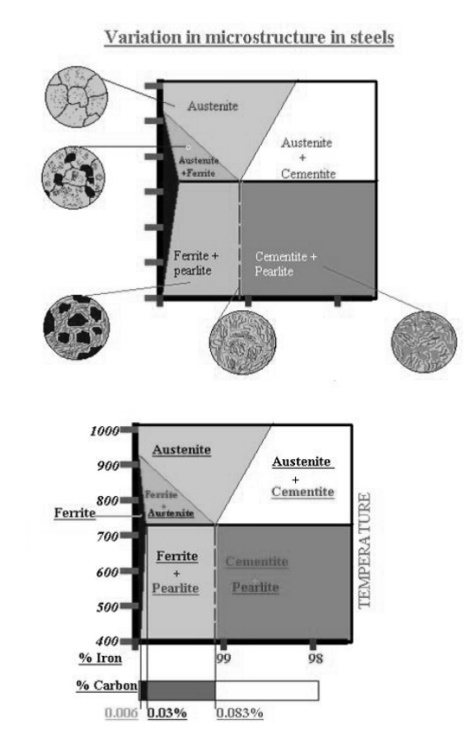

compositions of the iron-carbon alloys at room temperature

o

Hypoeutectoid steels (carbon content from 0 to 0.83%) consist of primary

(proeutectoid) ferrite (according to the curve A3) and pearlite.

o

Eutectoid steel (carbon content 0.83%) entirely consists of pearlite.

o

Hypereutectoid steels (carbon content from 0.83 to 2.06%) consist of primary

(proeutectoid) cementite (according to the curve ACM) and pearlite.

o Cast

irons (carbon content from 2.06% to

4.3%) consist of proeutectoid cementite C2 ejected from austenite according to

the curve ACM , pearlite and transformed ledeburite (ledeburite in

which austenite transformed to pearlite).

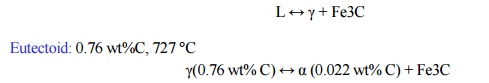

At 4.3%

carbon composition, on cooling Liquid phase is converted in to two solids

hence

forming Eutectic reaction.

L ↔ γ +

Fe3C

Eutectoid: 0.76 wt%C, 727 °C

γ(0.76

wt% C) ↔ α (0.022 wt% C) + Fe3C

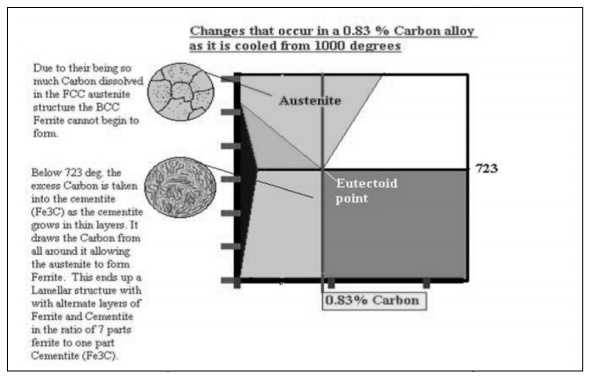

Shown

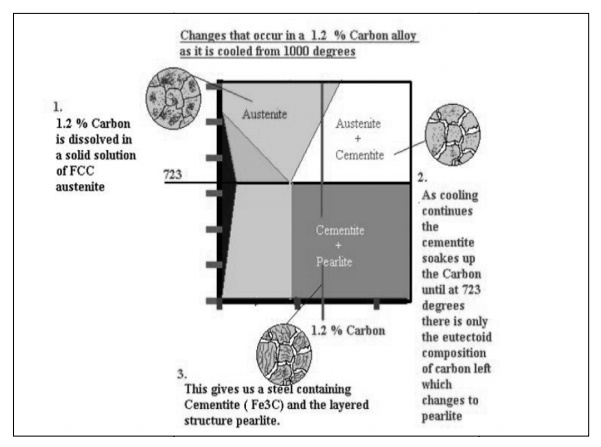

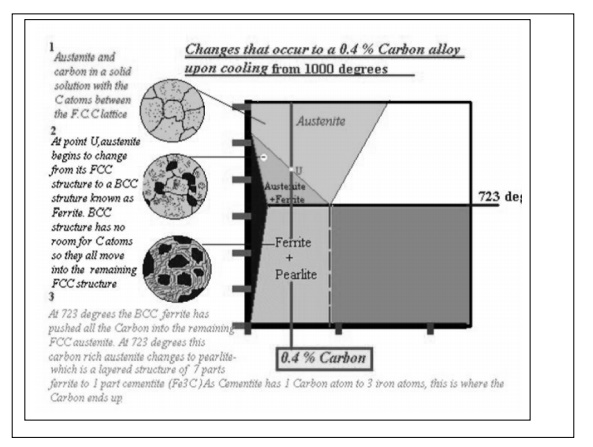

below is the steel part of the iron carbon diagram containing up to 2% Carbon.

At the eutectoid point 0.83% Carbon, Austenite which is in a solid solution

changes directly into a solid known as Pearlite which is a layered structure

consisting of layers of Ferrite and Cementite

8. METAL TYPES

The

metals that Steelworkers work with are divided into two general

classifications: ferrous and nonferrous. Ferrous metals are those composed

primarily of iron and iron alloys. Nonferrous metals are those composed

primarily of some element or elements other than iron. Nonferrous metals or

alloys sometimes contain a small amount of iron as an alloying element or as an

impurity.

1.FERROUS METALS

Ferrous

metals include all forms of iron and steel alloys. A few examples include

wrought iron, cast iron, carbon steels, alloy steels, and tool steels. Ferrous

metals are iron- base alloys with small percentages of carbon and other elements

added to achieve desirable properties. Normally, ferrous metals are magnetic

and nonferrous metals are nonmagnetic.

IRON

Pure iron

rarely exists outside of the laboratory. Iron is produced by reducing iron ore

to pig iron through the use of a blast furnace. From pig iron many other types

of iron and steel are produced by the addition or deletion of carbon and

alloys. The following paragraphs discuss the different types of iron and steel

that can be made from iron ore.

PIG IRON

Pig iron is composed of about 93% iron, from 3% to

5% carbon, and various amounts of other elements. Pig iron is comparatively

weak and brittle; therefore, it has a limited use and approximately ninety

percent produced is refined to produce steel. Cast-iron pipe and some fittings

and valves are manufactured from pig iron.

WROUGHT IRON

Wrought iron is made from pig iron with some slag

mixed in during manufacture. Almost pure iron; the presence of slag enables

wrought iron to resist corrosion and oxidation. The chemical analyses of

wrought iron and mild steel are just about the same. The difference comes from

the properties controlled during the manufacturing process. Wrought iron can be

gas and arc welded, machined, plated, and easily formed; however, it has a low

hardness and low-fatigue strength.

CAST IRON

Cast iron is any iron containing greater than 2%

carbon alloy. Cast iron has a high- compressive strength and good wear

resistance; however, it lacks ductility, malleability, and impact strength.

Alloying it with nickel, chromium, molybdenum, silicon, or vanadium improves

toughness, tensile strength, and hardness. A malleable cast iron is produced

through a easily as the low-carbon steels. They are used for crane prolonged

annealing process. hooks, axles, shafts, setscrews, and so on.

INGOT IRON

Ingot iron is a commercially pure iron (99.85%

iron) that is easily formed and possesses good ductility and corrosion

resistance. The chemical analysis and properties of this iron and the lowest

carbon steel are practically the same. The lowest carbon steel, known as dead-

soft, has about 0.06% more carbon than ingot iron. In iron the carbon content

is considered an impurity and in steel it is considered an alloying element.

The primary use for ingot iron is for galvanized and enameled sheet.

STEEL

All the different metals and materials that we

use in our trade, steel is by far the most important. When steel was developed,

it revolutionized the American iron industry. With it came skyscrapers,

stronger and longer bridges, and railroad tracks that did not collapse. Steel

is manufactured from pig iron by

decreasing the amount of carbon and other impurities and adding specific

amounts of alloying elements. Do not confuse steel with the two general classes

of iron: cast iron (greater than 2% carbon) and pure iron (less than 0.15% carbon). In steel manufacturing, controlled

amounts of alloying elements are added during the molten stage to produce the

desired composition. The composition of a steel is determined by its

application and the specifications that

were developed by the following: American Society for Testing and Materials

(ASTM), the American Society of Mechanical Engineers (ASME), the Society of

Automotive Engineers (SAE), and the American Iron and Steel Institute

(AISI).Carbon steel is a term applied to a broad range of steel that falls between the

commercially pure ingot

iron and the cast irons. This range of carbon steel may be classified

into four groups:

HIGH-CARBON STEEL/VERY HIGH-CARBON STEEL

Steel in these

classes respond well

to heat treatment

and can be welded. When welding, special electrodes

must be used along with preheating and stress- relieving procedures to prevent

cracks in the weld areas. These steels are

used for dies, cutting

tools, milltools, railroad car

wheels, chisels, knives, and so on.

LOW-ALLOY, HIGH-STRENGTH, TEMPERED STRUCTURAL

STEEL

A special

lowcarbon steel, containing specific small amounts of alloying elements, that

is quenched and tempered to get a yield strength of greater than 50,000

psi and tensile

strengths of 70,000 to

120,000 psi. Structural members

made from these high-strength steels may

have smaller cross- sectional areas than

common structural steels

and still have equal or greater strength. Additionally,

these steels are normally more corrosion- and abrasionresistant.

High-strength

steels are covered by ASTM specifications. NOTE: This type of

steel is much tougher than low-carbon

steels. Shearing machines for this type of steel must have twice the

capacity than that required for low-carbon steels

STAINLESS STEEL

This type

of steel is classified by the American Iron and Steel Institute (AISI) into two

general series named the 200-300 series and 400 series. Each series includes several

types of steel with different characteristics. The 200-300 series of stainless

steel is known as

AUSTENITIC.

This

type of steel

is very tough and ductile in the as-welded condition; therefore, it is ideal for welding and requires no annealing

under normal atmospheric conditions.

The most well-known types of steel

in this series are the 302 and

304. They are commonly called

18-8 because they are composed of 18% chromium and 8% nickel.

The

chromium nickel steels

Low-Carbon

Steel . . . 0.05% to 0.30% carbon are

the most widely used

and are

normally nonmagnetic.

Medium-Carbon

Steel . . . 0.30% to 0.45% carbon

High-Carbon

Steel . . . 0.45% to0.75% carbon their

crystalline structure

into two

general groups.

One Very

High-Carbon Steel . . . 0.75% to 1.70% carbon group is known as

FERRITIC

CHROMIUM and the other group as MARTENSITIC CHROMIUM.

2.ALLOY STEELS

Steels

that derive their properties primarily from the presence of alloying element other

than carbon are called ALLOYS or ALLOY STEELS. Note, however, that alloy steels

always contain traces of other elements. Among the more common alloying

elements are nickel, chromium, vanadium, silicon, and tungsten. One or more of

these elements may be added to the steel during the manufacturing process to

produce the desired characteristics.

Alloy

steels may be produced in structural sections, sheets, plates, and bars for use

in the as rolled condition. Better physical properties are obtained with these

steels than are possible with hot. These alloys are used in structures where

the strength of material is especially important. Bridge members, railroad

cars, dump bodies, dozer blades, and crane booms are made from alloy steel.

Some of the common alloy steels are briefly described in the paragraphs below.

NICKEL STEELS

These

steels contain from 3.5% nickel to 5% nickel. The nickel increases the strength

and toughness of these steels. Nickel steel containing more than 5% nickel has

an increased resistance to corrosion and scale. Nickel steel is used in the

manufacture of aircraft parts, such as propellers and airframe support members.

CHROMIUM STEELS

These

steels have chromium added to improve hardening ability, wear resistance, and

strength. These steels contain between 0.20% to 0.75% chromium and 0.45% carbon

or more. Some of these steels are so highly resistant to wear that they are

used for the races and balls in antifriction bearings.

Chromium

steels are highly resistant to corrosion and to scale.

CHROME VANADIUM STEEL

This steel has the maximum amount of strength with

the least amount of weight. Steels of this type contain from 0.15% to 0.25%

vanadium, 0.6% to 1.5% chromium, and 0.1% to 0.6% carbon. Common uses are for

crankshafts, gears, axles, and other items that require high strength. This

steel is also used in the manufacture of high-quality hand tools, such as

wrenches and sockets.

TUNGSTEN STEEL

This is a special alloy that has the property of

red hardness. This is the ability to continue to cut after it becomes red-hot.

A good grade of this steel contains from 13% to 19% tungsten, 1% to 2%

vanadium, 3% to 5% chromium, and 0.6% to 0.8% carbon. Because this alloy is

expensive to produce, its use is largely restricted to the manufacture of drills,

lathe tools, milling cutters, and similar cutting tools.

MOLYBDENUM

This is

often used as an alloying agent for steel in combination with chromium and

nickel. The molybdenum adds toughness to the steel. It can be used in place of

tungsten to make the cheaper grades of high-speed steel and in carbon

molybdenum high-pressure tubing.

MANGANESE STEELS

The amount of manganese used depends upon the

properties desired in the finished product. Small amounts of manganese produce

strong, free-achgining steels. Larger amounts (between 2% and 10%) produce a

somewhat brittle steel, while still larger amounts (11% to 14%) produce a steel

that is tough and very resistant to wear after proper heat treatment.

3. NONFERROUS METALS

Nonferrous

metals contain either no iron or only insignificant amounts used as an

alloy.

Some of the more common nonferrous metals

Steelworkers work with are as follows: copper, brass, bronze, copper-nickel

alloys, lead, zinc, tin, aluminum, and Duralumin. NOTE: These metals are nonmagnetic.

COPPER

This

metal and its alloys have many desirable properties. Among the commercial

metals, it is one of the most popular. Copper is ductile, malleable, hard,

tough, strong, wear resistant, machinable, weld able, and corrosion resistant.

It also has high-tensile strength, fatigue strength, and thermal and electrical

conductivity. Copper is one of the easier metals to work with but be careful

because it easily becomes work-hardened; however, this condition can be

remedied by heating it to a cherry red and then letting it cool. This process,

called annealing, restores it to a softened condition. Annealing and softening

are the only heat-treating procedures that apply to copper. Seams in copper are

joined by riveting, silver brazing, bronze brazing, soft soldering, gas

welding, or electrical arc welding. Copper is frequently used to give a

protective coating to sheets and rods and to make ball floats, containers, and

soldering coppers.

CARBON STEELS

Carbon

steels are iron-carbon alloys containing up to 2.06% of carbon, up to1.65% of

manganese, up to 0.5% of silicon and sulfur and phosphorus as impurities.

Carbon content in carbon steel determines its strength and ductility. The

higher carbon content, the higher steel strength and the lower its ductility.

According to the steels classification there are following groups of carbon

steels:

• Low

carbon steels (C < 0.25%)

• Medium

carbon steels (C =0.25% to 0.55%)

• High

carbon steels (C > 0.55%)

• Tool

carbon steels (C>0.8%)

Designation

system of carbon steels Chemical compositions of some carbon steels Properties

of some carbon steels

Low carbon steels (C < 0.25%)

Properties:

good formability and weldability, low strength, low cost.

Applications:

deep drawing parts, chain, pipe, wire, nails, some machine parts.

Medium carbon steels (C =0.25% to 0.55%)

Properties:

good toughness and ductility, relatively good strength, may be hardened by

quenching

Applications:

rolls, axles, screws, cylinders, crankshafts, heat treated machine parts.

High carbon steels (C > 0.55%)

Properties:

high strength, hardness and wear resistance, moderate ductility.

Applications:

rolling mills, rope wire, screw drivers, hammers, wrenches, band saws.

Tool carbon steels (C>0.8%) -

subgroup of high carbon steels

Properties:

very high strength, hardness and wear resistance, poor weldability, low

ductility.

Applications:

punches, shear blades, springs, milling cutters, knives, razors. Designation

system of

carbon steels

American

Iron and Steel Institute (AISI) together with Society of Automotive Engineers

(SAE)

have established four-digit (with additional letter prefixes) designation

system:

LOW-ALLOY, HIGH-STRENGTH, TEMPERED STRUCTURAL STEEL

A special

lowcarbon steel, containing specific small amounts of alloying elements, that

is quenched and tempered to get a yield strength of greater than 50,000 psi and

tensile strengths of 70,000 to 120,000 psi. Structural members made from these

high-strength steels may have smaller cross- sectional areas than common

structural steels and still have equal or greater strength. Additionally, these

steels are normally more corrosion- and abrasionresistant. High-strength steels

are covered by ASTM specifications. NOTE: This type of steel is much tougher

than low-carbon steels. Shearing machines for this type of steel must have

twice the capacity than that required for low-carbon steels

STAINLESS STEEL

This type

of steel is classified by the American Iron and Steel Institute (AISI) into two

general series named the 200-300 series and 400 series. Each series includes

several types of steel with different characteristics. The 200-300 series of

stainless steel is known as austenitic.

AUSTENITIC

This type

of steel is very tough and ductile in the as-welded condition; therefore, it is

ideal for welding and requires no annealing under normal atmospheric

conditions. The most well-known types of steel in this series are the 302 and

304. They are commonly called 18-8 because they are composed of 18% chromium

and 8% nickel. The chromium nickel steels Low-Carbon SAE 1XXX

First

digit 1 indicates carbon steel (2-9 are used for alloy steels); Second digit

indicates modification of the steel.

0 - Plain

carbon, non-modified

1 -

Resulfurized

2 -

Resulfurized and rephosphorized

5 -

Non-resulfurized, Mn over 1.0%

Last two

digits indicate carbon concentration in 0.01%.

Example:

SAE 1030 means non modified carbon steel, containing 0.30% of carbon.

A letter

prefix before the four-digit number indicates the steel making technology:

A - Alloy, basic open hearth

B - Carbon, acid

Bessemer

C - Carbon, basic open hearth

D - Carbon, acid open hearth

E -

Electric furnace

Example:

AISI B1020 means non modified carbon steel, produced in acid Bessemer and

containing 0.20% of carbon.

Chemical

compositions of some carbon steels

SAE/AISI

grade C, % Mn,% P,% max S,% max

1006 0.08 max 0.35 max 0.04 0.05

1010 0.08-0.13 0.30-0.60 0.04 0.05

1020 0.17-0.23 0.30-0.60 0.04 0.05

1030 0.27-0.34 0.60-0.90 0.04 0.05

1045 0.42-0.50 0.60-0.90 0.04 0.05

1070 0.65-0.76 0.60-0.90 0.04 0.05

1090 0.85-0.98 0.60-0.90 0.04 0.05

1117 0.14-0.20 1.10-1.30 0.04 0.08-0.13

1547 0.43-0.51 1.35-1.65 0.04 0.05

Related Topics