Chapter: Mechanical and Electrical : Thermal Engineering : Gas Power Cycles

Gas Power Cycles

GAS POWER CYCLES

PREREQUISITE DISCUSSIONS

Discussion of this gas power

cycles will involve the study of those heat engines in which the working fluid

remains in the gaseous state throughout the cycle. We often study the ideal

cycle in which internal irreversibilities and complexities (the actual intake

of air and fuel, the actual combustion process, and the exhaust of products of

combustion among others) are removed. We will be concerned with how the major

parameters of the cycle affect the performance of heat engines. The performance

is often measured in terms of the cycle efficiency.

INTRODUCTION

Ø The cycle

is defined as the repeated series of operation or processes performed on a

system, so that the system attains its original state.

Ø The cycle

which uses air as the working fluid is known as Gas power cycles.

Ø In the

gas power cycles, air in the cylinder may be subjected to a series of

operations which causes the air to attain to its original position.

Ø The

source of heat supply and the sink for heat rejection are assumed to be

external to the air.

Ø The cycle

can be represented usually on p-V and T-S diagrams.

POWER CYCLES

Ø Ideal

Cycles, Internal Combustion

Ø Otto

cycle, spark ignition

Ø Diesel

cycle, compression ignition

Ø Sterling

& Ericsson cycles

Ø Brayton

cycles

Ø Jet-propulsion

cycle

Ø Ideal

Cycles, External Combustion

Ø Rankine

cycle

IDEAL CYCLES

Ø Idealizations

& Simplifications

Ø Cycle

does not involve any friction

Ø All

expansion and compression processes are quasi-equilibrium processes

Ø Pipes

connecting components have no heat loss

Ø Neglecting

changes in kinetic and potential energy (except in nozzles & diffusers)

GAS POWER CYCLES

Ø Working

fluid remains a gas for the entire cycle

Ø Examples:

Ø Spark-ignition

engines

Ø Diesel

engines

Ø Gas

turbines

Air-Standard Assumptions

Ø Air is

the working fluid, circulated in a closed loop, is an ideal gas

Ø All

cycles, processes are internally reversible

Ø Combustion

process replaced by heat-addition from external source

Ø Exhaust

is replaced by heat rejection process which restores working fluid to initial

state

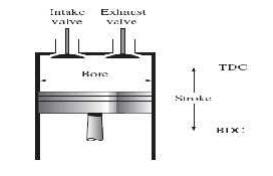

ENGINE TERMS

Ø Top dead

center

Ø Bottom

dead center

Ø Bore

Ø Stroke

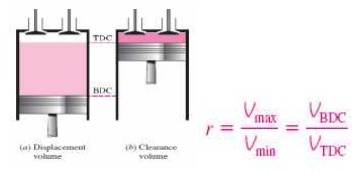

Ø Clearance

volume

Ø Displacement

volume

Ø Compression

ratio

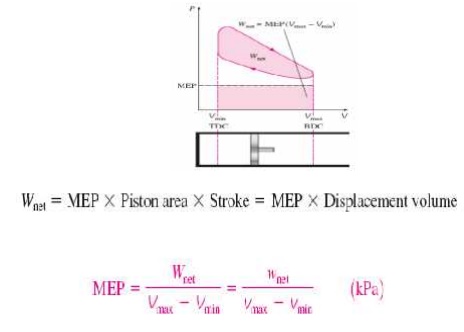

Ø Mean effective pressure (MEP)

CYCLES

AND THEIR CONCEPTS

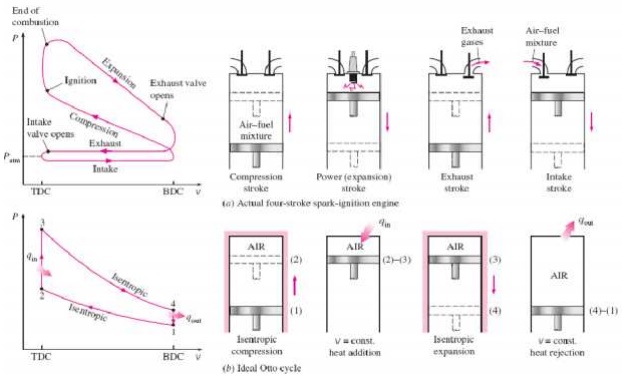

OTTO CYCLE

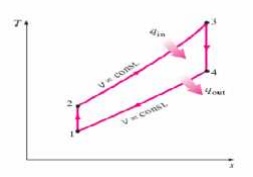

An Otto cycle is an

idealized thermodynamic cycle that describes the functioning of a typical spark

ignition piston engine. It is the thermodynamic cycle most commonly found in

automobile engines. The idealized diagrams of a four-stroke Otto cycle Both diagrams

Ø Petrol

and gas engines are operated on this cycle

Ø Two

reversible isentropic or adiabatic processes

Ø Two constant volume process

PROCESS OF OTTO CYCLE

Ø Ideal Otto

Cycle

Ø Four

internally reversible processes

o 1-2 Isentropic compression

o 2-3 Constant-volume heat

addition

o 3-4 Isentropic expansion

o 4-1 Constant-volume heat rejection

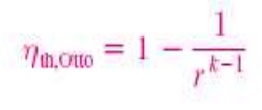

Thermal efficiency of ideal Otto

cycle:

Since V2= V3

and V4 = V 1

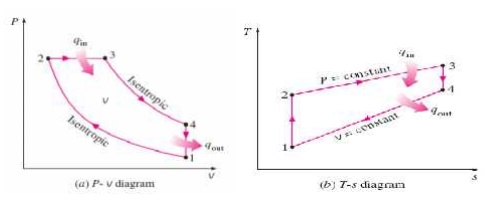

Diesel cycle

The Diesel cycle is a co mbustion

process of a reciprocating internal co mbustion engine. In it, fuel is ignited

by hea t generated during the compression of air in the combustion chamber,

into which fuel is t hen injected.

It is assumed to have constant

pressure during the initial part of the "combustion" phase The Diesel

engine is a

heat engine: it

converts heat into work.

During the bottom isentropic processes (blue), energy is transferred

into the system in the form of work , Win

but by definition (isentropic) no ene rgy is transferred into or out of the

system in the form of heat. During the constant pressure ( red, isobaric)

process, energy enters the syste m as heat

. During the top isentropic processes (yellow), energy is transferred

out of the sy stem in the form of Wout,

but by definition (isen tropic) no energy is transferred into or out of the

system in the form of heat. During the constan t volume (green,isochoric)

process, some of energy flows out of the system as heat through the right

depressurizing process Qout . The wor k that leaves the system is

equal to the work that enters the system plus the difference between the heat

added to the system and the heat that lea ves the system; in other words, net

gain of wo rk is equal to the difference between the heat adde d to the system

and the heat that leaves the system.

PROCESSES OF DIESEL CYCLE:

Ø 1-2

Isentropic com pression

Ø 2-3

Constant-Pres sure heat addition

Ø 3-4

Isentropic expansion

Ø 4-1

Constant-volume heat rejection

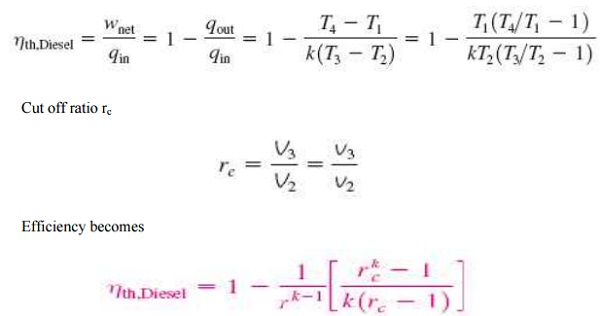

For ideal diesel cycle

Cut off ratio rc

DUAL CYCLE

The dual combustion cycle (also

known as the limited pressure or mixed cycle) is a thermal cycle that is a

combination of the Otto cycle and the Diesel cycle. Heat is added partly at

constant volume and partly at constant pressure, the advantage of which is that

more time is available for the fuel to completely combust. Because of lagging

characteristics of fuel this cycle is invariably used for diesel and hot spot

ignition engines.

Ø Heat addition

takes place at constant volume and constant pressure process .

Ø Combination

of Otto and Diesel cycle.

Ø Mixed

cycle or limited pressure cycle

PROCESS OF DUAL CYCLE

Ø Isentropic

compression

Ø Constant-volume

heat rejection

Ø Constant-pressure

heat addition

Ø Isentropic

expansion

Ø Constant-volume

heat rejection

The cycle is the equivalent air cycle for reciprocating high

speed compression ignition engines. The P-V and T-s diagrams are shown in

Figs.6 and 7. In the cycle, compression and expansion processes are isentropic;

heat addition is partly at constant volume and partly at constant pressure

while heat rejection is at constant volume as in the case of the Otto and

Diesel cycles.

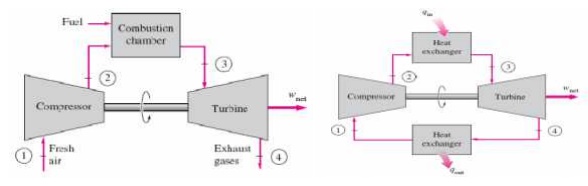

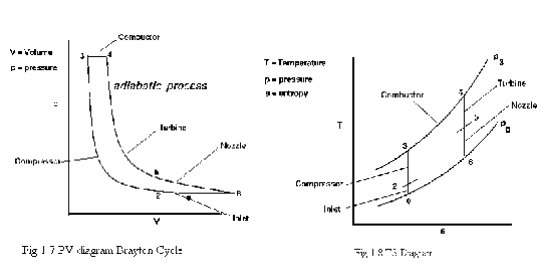

BRAYTON CYCLE

The Brayton cycle is a

thermodynamic cycle that describes the workings of a constant pressure heat

engine. Gas turbine engines and airbreathing jet engines use the Brayton Cycle.

Although the Brayton cycle is usually run as an open system (and indeed must be

run as such if internal combustion is used), it is conventionally assumed for

the purposes of thermodynamic analysis that the exhaust gases are reused in the

intake, enabling analysis as a closed system. The Ericsson cycle is similar to

the Brayton cycle but uses external heat and incorporates the use of a

regenerator.

Ø Gas

turbine cycle

Ø Open vs

closed system model

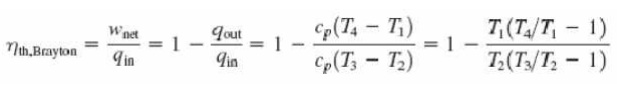

With cold-air-standard assumptions

Ø Since

processes 1-2 and 3-4 are isentropic, P2 = P3 and P4 = P1

REAL TIME APPLICATIONS

PETROL ENGINES

Ø Datsun Go

Ø Hyundai

Xcent

Ø Maruti

Suzuki Celerio

Ø Volkswagen

Vento

Ø Nissan

Terrano

DIESEL ENGINES

Ø Isuzu

Diesel Cars

Ø Datsun

Diesel Cars

Ø Ashok

Leyland Diesel Cars

GAS TURBINES

Ø Indraprastha

(Delhi) CCGT Power Station India

Ø Kovilkalappal

(Thirumakotai) Gas CCGT Power Station India

Ø Lanco

Tanjore (Karuppur) CCGT Power Plant India

TECHNICAL TERMS

Ø TDC: Top

Dead Center: Position of the piston where it forms the smallest volume

Ø BDC: Bottom Dead Center: Position of the piston

where it forms the largest volume

Ø Stroke: Distance between TDC and BDC

Ø Bore :

Diameter of the piston (internal diameter of the cylinder)

Ø Clearance

volume: ratio of maximum volume to minimum volume VBDC/VTDC

Ø Engine displacement

: (no

of cylinders) x (stroke length) x (bore area) (usually given in cc or

liters)

Ø MEP: mean

effective pressure: A const. theoretical pressure that if acts on piston produces

work same as that during an actual cycle

Ø Gas Power

Cycles: Working fluid remains in the gaseous state through the cycle.

Sometimes useful to study an idealised cycle in which internal

irreversibilities and complexities are removed. Such cycles are called:Air

Standard Cycles

Ø The mean

effective pressure (MEP): A fictitious pressure that, if it were

applied to the piston during the power stroke, would produce the same

amount of net work as that produced during the actual cycle.

Ø Thermodynamics:

Thermodynamics

is the science of the relations between heat ,work and the properties of

system

Ø Boundary:

System

is a fixed and identifiable collection of matter enclosed by a real or imaginary

surface which is impermeable to matter but which may change its shape or

volume. The surface is called the boundary

Ø Surroundings:

Everything

outside the system which has a direct bearing on the system's behavior.

Ø Extensive

Property: Extensive properties are those whose value is the sum of the

values for each subdivision of the system, eg mass, volume.

Ø Intensive

Property: Properties are those which have a finite value as the size of

the system approaches zero, eg pressure, temperature, etc.

Ø Equilibrium:

A

system is in thermodynamic equilibrium if no tendency towards spontaneous

change exists within the system. Energy transfers across the system

disturb the equilibrium state of the system but may not shift the system

significantly from its equilibrium state if carried out at low rates of change.

I mentioned earlier that to define the properties of a system, they have to be

uniform throughout the system.

Therefore to define the state of system, the

system must be in equilibrium. Inequilibrium of course implies non-uniformity

of one or more properties).

Ø Isentropic

process: Isentropic process is one in which for purposes of engineering

analysis and calculation, one may assume that the process takes place from

initiation to completion without an increase or decrease in the entropy of the

system, i.e., the entropy of the system remains constant.

Ø Isentropic

flow: An isentropic flow is a flow that is both adiabatic and

reversible. That is, no heat is added to the flow, and no energy

transformations occur due to friction or dissipative effects. For an isentropic

flow of a perfect gas, several relations can be derived to define the pressure,

density and temperature along a streamline.

Ø Adiabatic

heating: Adiabatic heating occurs when the pressure of a gas is

increased from work done on it by its surroundings, e.g. a piston.

Diesel engines rely on adiabatic heating during their compression.

Ø Adiabatic

cooling: Adiabatic cooling occurs when the pressure of a substance is

decreased as it does work on its surroundings. Adiabatic cooling occurs in

the Earth's atmosphere with orographic lifting and lee waves, When the pressure

applied on a parcel of air decreases, the air in the parcel is allowed to

expand; as the volume increases, the temperature falls and internal energy

decreases.

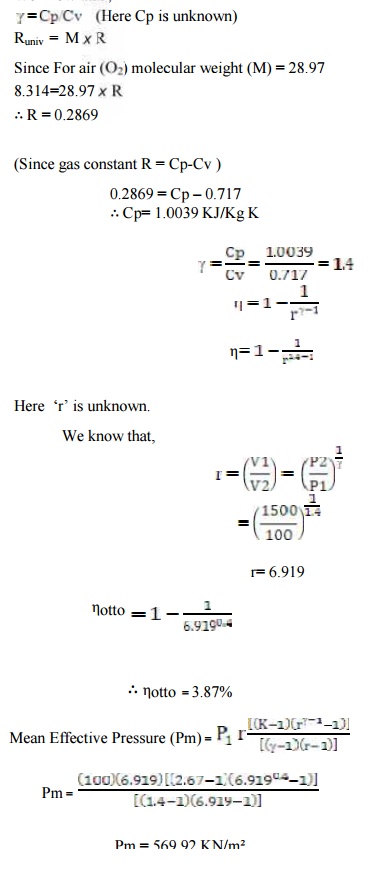

SOLVED PROBLEMS

1. In an Otto cycle air at 1bar and 290K is

compressed isentropic ally until the pressure is 15bar The heat is added at

constant volume until the pressure rises to 40bar. Calculate the air standard

efficiency and mean effective pressure for the cycle. Take Cv=0.717 KJ/Kg K and

Runiv = 8.314KJ/Kg K.

Given Data:

Pressure

(P1) = 1bar = 100KN/m2

Temperature(T1)

= 290K

Pressure

(P2) = 15bar = 1500KN/m2

Pressure

(P3) = 40bar = 4000KN/m2

Cv =

0.717 KJ/KgK

Runiv

= 8.314 KJ/Kg K

To Find:

i) Air Standard Efficien cy (ηotto) ii)

Mean Effective Press ure (Pm)

Solution:

Here

it is g Runiv = 8.314 KJ/Kg K

We

know

2.

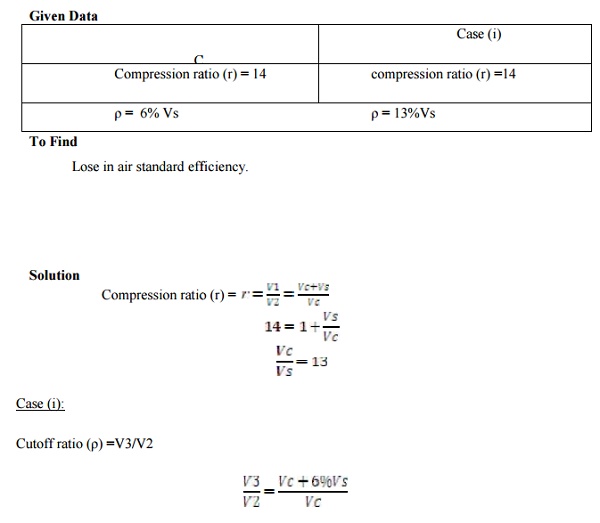

Estimate the lose in air st andard efficiency for the diesel engine for the c

ompression ratio 14 and the cutoff change s from 6% to 13% of the stroke.

=55.93%

Lose in

air standard efficiency = (ηdiesel

CASE(i) ) - (ηdiesel

CASE(i) )

= 0.6043-0.5593

= 0.0449

= 4.49%

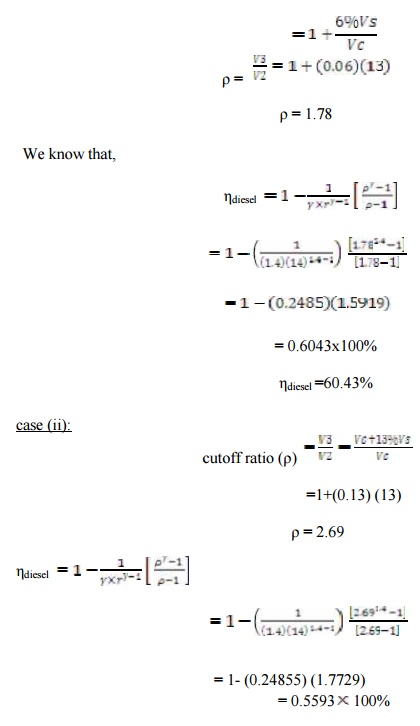

3.

The compression ratio o f an air standard

dual cycle is 12 and the maximum pressure on the cycle is limited to 70bar. Th

e pressure and temperature of the cycle at the b eginning of compression

process are 1bar a nd 300K. Calculate the thermal efficiency and M ean

Effective Pressure. Assume cylinder bore = 250mm, Stroke length = 300mm,

Cp=1.005K J/Kg K, Cv=0.718KJ/Kg K.

Given

data:

Assume Qs1

= Qs2

Compression

ratio (r) = 12

Maximum

pressure (P3) = (P4) = 7000 KN/m2

Temperature

(T1) = 300 K

Diameter

(d) = 0.25m

Stroke

length (l) = 0.3m

To find:

Dual

cycle efficiency (ηdual)

Mean

Effective Pressure (P m)

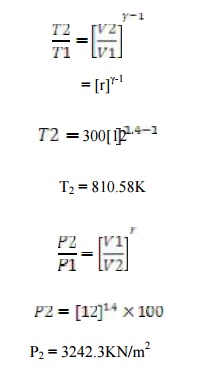

Solution:

By Process

1-2:

= 832.58/0.0147

Pm = 56535 KN/m2

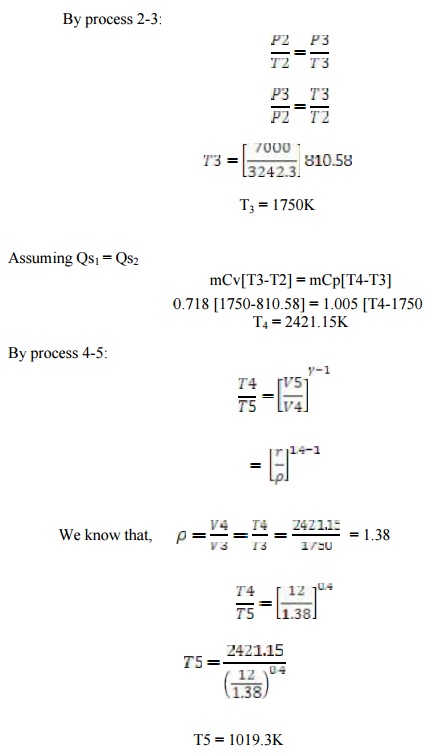

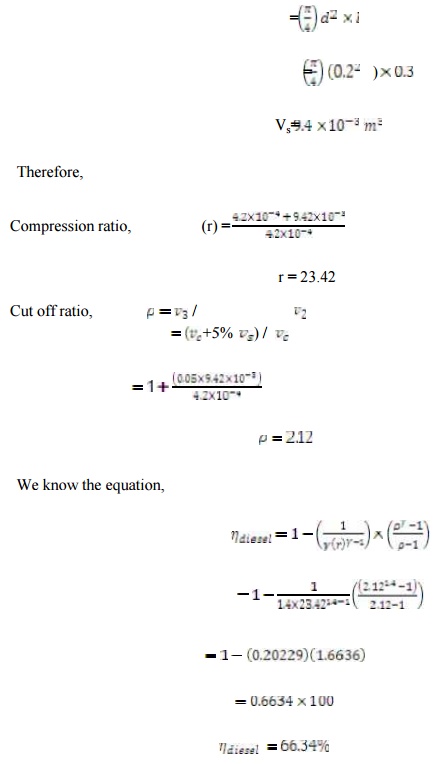

4.A diesel engine

operating an air standard

diesel cycle has 20cm bore

and 30cmstroke.the clearance volu me is 420cm3.if the fuel is

injected at 5% of the stroke,find the air standard efficiency.

Given Data:-

Bore

diameter (d) =20cm=0.2mk

Stroke,

(l) =30cm=0.3m

Clearance volume, (v2

) =420cm3=420/1003= ![]()

![]()

![]() m3

m3

To Find:-

Air standard efficiency, (diesel)

Solution:-

Compression ratio,

r = v1/v2

= (vc+vs)/vc

We know that,

Stroke vo lume, vs=area*length

Related Topics