Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Flexible Manufacturing Systems

Flexible Manufacturing Systems(FMS) Components

FMS

COMPONENTS

As

indicated in Out definition. there are several basic components of an FMS: (1)

workstations, (2) material handling and storage system, and (3) computer

control system. In addition, even though an FMS is highly automated, (4) people

are required to manage and operate the system. We discuss these four FMS

components in this section.

Workstations

The

processing or assembly equipment used in an FMS depends on the type of work

accomplished by the

system. In a system designed for machining operations, the principle types of

processing station are CNC machine tools. However, the FMS concept is also applicable

to various other processes as well. Following are the types of workstations

typically found in an FMS.

Load/Unload Stations. The

load/unload station is the physical interface between the FMS and the rest of the factory. Raw work-parts enter the system

at this point, and finished parts exit the system from here. Loading and

unloading can be accomplished either manually or by automated handling systems. Manual loading and unloading is prevalent

in most FMSs today. The load/unload station should be ergonomically designed to

permit convenient and safe movement of work parts. For parts that are too heavy

to lift by the operator, mechanized cranes and other handling devices are

installed to assist the operator.

A

certain level of cleanliness must be maintained at the workplace. and air

hoses or other washing facilities are

often required to flush away chips and ensure clean mounting and locating

points. The station is often raised slightly above floor level using an open-grid

platform to permit chips and cutting fluid to drop through the openings for

subsequent recycling or disposal

The

load/unload station should include a data entry unit and monitor for

communication between the operator and the computer system. Instructions must

be given to the operator regarding which part to load onto the next pallet to

adhere to the production schedule. In cases when different pallets are required

for different parts, the correct pallet must be supplied to the station. In

cases where modular fixturing is used, the correct fixture must be specified.

and the required components and tools must be available at the workstation to

build it. 'When the part loading procedure has been completed. the handling

system must proceed to launch the pallet into the system; however, the handling

system must be prevented from moving the pallet while the operator is still

working. All of these circumstances require communication between the computer

system and the operator at the load/unload station

Machining Stations. The most

common applications of FMSs arc machining operations, The workstations used in

these systems are therefore predominantly CNC machine tools. Most common is the

CNC

machining center (Section 14.3.3): in particular.

the horizontal rnachining center. CNC machining centers possess features that

make them compatible with the FMS, including automatic tool changing and tool

storage, use of palletized work-parts, CNC, and

capacity for distributed numerical control (DNC) (Section 6.3). Machining

centers can be ordered with automatic pallet changers that can be readily

interfaced with the FMS part handling system. Machining centers are generally

used for non-rotational parts. For rotational parts, turning centers are used; and for parts that are mostly rotational

hut require multi-tooth rotational cutters (milling and drilling), mi11·turn centers can be used.

In some

machining systems, the types of operations performed are concentrated in a

certain category, such as milling or turning. For milling, special milling machine modules can be used to

achieve higher production levels than a machining center is capable of. The

milling module can be vertical spindle, horizontal spindle, or multiple

spindle. For turning operations. Special turning modules can be designed for the FMS, In conventional turning, the

work-piece IS rotated against a tool that is held in the machine and fed in a

direction parallel to the axis of work rotation. Parts made on most FMSs are

usually non-rotational: however, they may require some turning in their process

sequence. For these cases, the parts are held in a pallet fixture throughout

processing on the FMS, and a turning module is designed to rotate the single

point tool around the work.

Other Processing Stations.

The FMS concept has been applied to other processing operations in addition to

machining. One such application is sheet metal fabrication processes. The

processing workstations consist of press-working operations, such as punching, shearing,

and certain bending and forming processes. Also, flexible systems are being

developed to automate the forging process. Forging is traditionally a very

labor-intensive operation. The workstations in the system consist principally

of a heating furnace, a forging press. and a trimming station.

Assembly. Some FMSs

are designed to perform assembly operations. Flexible automated

assembly systems are being developed to replace manual labor in the assembly of

products typically made in batches. Industrial robots are often used as the

automated workstations in these flexible assembly systems. They can be

programmed to perform tasks with variations in sequence and motion pattern to

accommodate the different product styles assembled in the system. Other examples

of flexible assembly workstations are the programmable component placement

machines widely used in electronics assembly.

Other Stations and Equipment. Inspection

can be incorporated into an FMS, cither by including, an inspection operation

at a processing workstation or by including a station specifically designed for

inspection. Coordinate measuring machines (Section 23.4), special inspection

probes that can be used in a machine tool spindle (Section 23.4.b), and machine vision (Section 23.0) are three possible

technologies for performing inspection on an FMS. Inspection has been found to

be particularly important in flexible assembly systems to ensure that

components have been properly added at the workstations. We examine the topic of automated inspection in more

detail in Chapter 22 (Section 22.3).

In

addition to the above, other operations and functions are often accomplished on

an FMS. These include stations for cleaning parts and/or pallet fixtures.

central coolant de

livery

systems for the entire FMS, and centralized chip removal systems often

installed below floor level

Material

Handling and Storage System

The

second major component of an FMS is its material handling and storage system.

In this subsection, we discuss the functions of the handling system, material

handling equipment typically used in an FMS, and types of FMS layout.

Functions

of the Handling System. The material handling and storage system in an FMS

performs the fol1owing functions:

Random, independent

movement of work-parts between stations. This means that parts must be capable of moving from

anyone machine in the system to any other machine. to provide various

routing alternatives for the different parts and to make machine substitutions

when certain stations are busy.

Handle a

variety of work-part configurations. For prismatic parts, this is

usually accomplished by using modular pallet fixtures in the handling system.

The fixture is located on the top face of the pallet and is designed to

accommodate different part configurations by means of common components, quick change

features, and other devices that permit a rapid buildup of the fixture for a

given part. The base of the pallet is designed for the material handling

system. For rotational parts, industrial robots are often used to load and

unload the turning machines and to move parts between stations.

Temporary

storage. The number of parts in the FMS will typically exceed the number of parts

actually being processed at any moment. Thus, each station has a small queue of

parts waiting to be processed. which helps to increase machine utilization.

Convenient

access for loading and unloading work-parts. The handling system must include locations for load/unload stations.

Compatible with computer control. The

handling system must be capable of being controlled

directly by the computer system to direct it to the various workstations,

load/unload stations, and storage areas

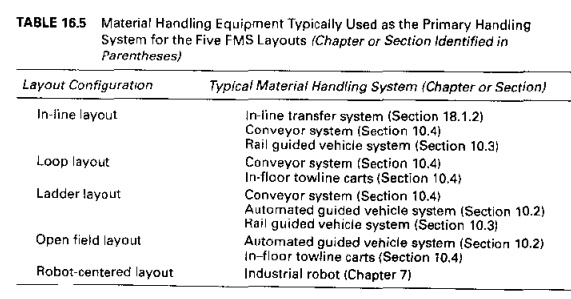

Material

Handling Equipment. The types of material handling systems used to transfer

parts between stations in an F.\1S include a variety of conventional material

transport equipment (Chapter 10), inline transfer mechanisms (Section

18.1.2),and industrial robots (Charter 7) The material handling function in an

FMS is often shared between two systems: (1) a primary handling system and (2)

a secondary handling system. The primary handling system establishes the basic layout of the FMS and is

responsible for moving work-parts

between stations in the system. The types of material handling equipment

typically utilized for FMS layouts are summarized in Table 16.5

The secondary handling system consists of

transfer devices, automatic pallet changers. and similar mechanisms located at

the workstations in the FMS. The function of the secondary handling system is

to transfer work from the primary system to the machine tool or other

processing station and to position the parts with sufficient accuracy and

repeatability to perform the processing or assembly operation. Other purposes

served by the secondary handling system include: (1) reorientation of the work-part

if necessary to present the surface that is to be processed and (2) buffer

storage of parts to minimize work change time and maximize station utilization.

In some FMS installations, the positioning and requirements at the individual

workstations are satisfied by the primary work handling system. In these cases,

the secondary handling system is not included,

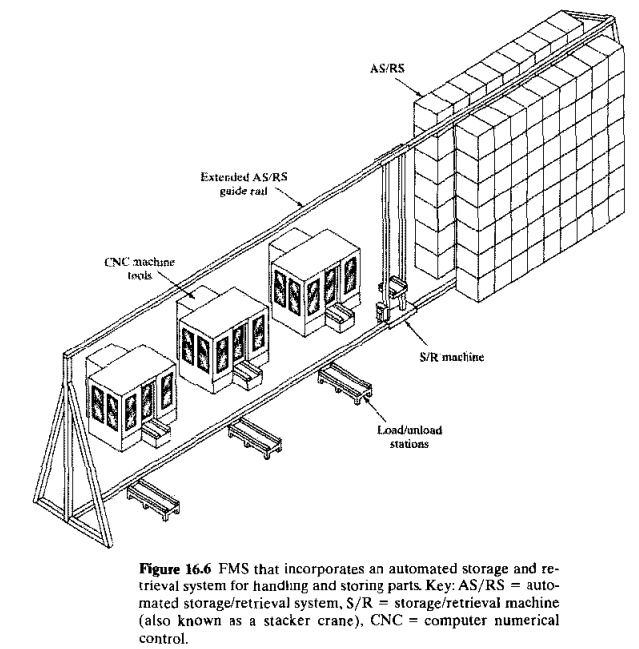

The

primary handling system is sometimes supported by an automated storage system

(Section: 1.4). An example of storage in an FMS is illustrated in Figure 16.6.

The FMS is integrated with an automated storage/retrieval system (AS/RS), and

the S/R machine serves the work handling function for the workstations as well

as delivering parts to and from the storage racks,

FMS

Layout Configurations. The material handling system establishes the FMS layout.

Most layout configurations found in today's FMSs can he divided into five

categories: (1) inline layout, (2) loop hl)'OU1, (3) ladder layout. (4) open

field layout, and (5) robot-centered cell.

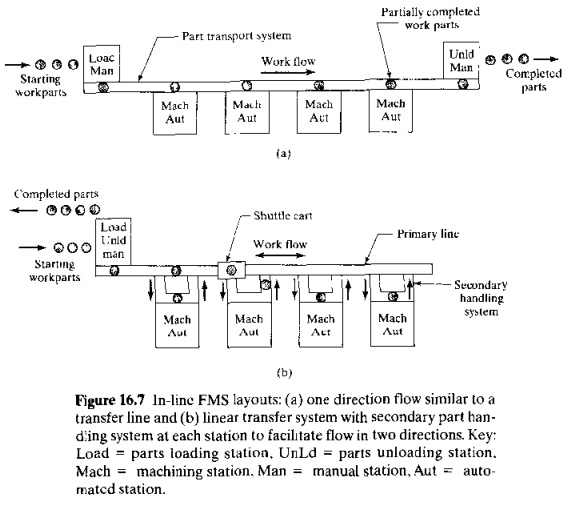

In the inline layout, the machines and handling

system are arranged in a straight line, as illustrated in Figure, 16.6 and

16.7. In its simplest form. the parts progress from one workstation to the next

in a well defined sequence, with work always moving in one direction and no

back flow, as in Figure 16.7(a). The operation of this type of system is similar

to a transfer lin., (Chapter 18). except that a variety of work-parts are

processed in the

TABLE 16.5

Material Handling Equipment Typically Used as the Primary Handling System

for the Five FMS Layouts (Chapter or Section Identified in

system.

Since all work units follow the same routing sequence, even though the

processing varies at each station, this system is classified as type III A in

our manufacturing systems classification system. For inline systems requiring

greater routing flexibility, a linear transfer system that permits movement in

two directions can be installed. One possible arrangement for doing this is

shown in Figure 16.7(b), in which a secondary work handling system is provided

at each workstation to separate most of the parts from the primary line. Because

of the variations in routings, this is II

type II A manufacturing system.

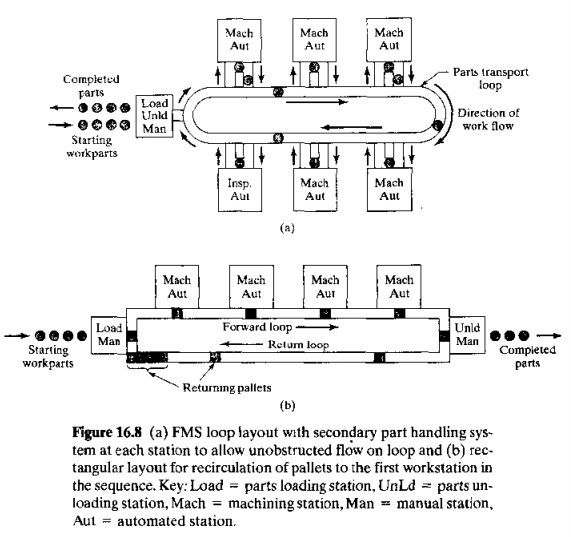

In the loop layout, the workstations are

organized in a loop that is served by II part

handling system in the same shape, as shown in Figure 16.8(a). Parts usually

flow in one direction around the loop, with the capability to stop and be

transferred to any station. A secondary

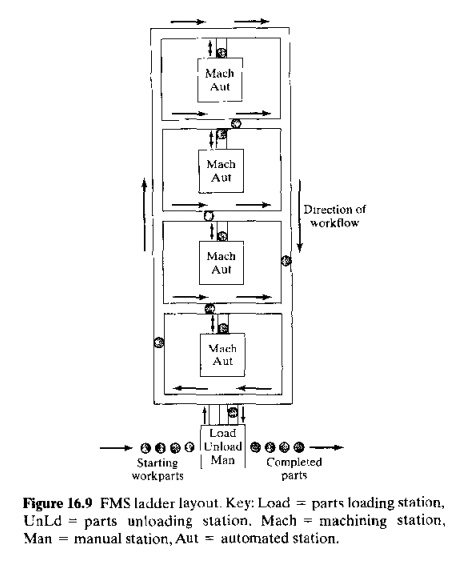

The ladder layout consists of a loop with

rungs between the straight sections of the loop, on which workstations are

located, as shown in Figure 16.9.The rungs increase the possible ways of

getting from one machine to the next, and obviate the need for a secondary

handling system. This reduces average travel distance and minimizes congestion

in the handling system, thereby reducing transport time between workstations.

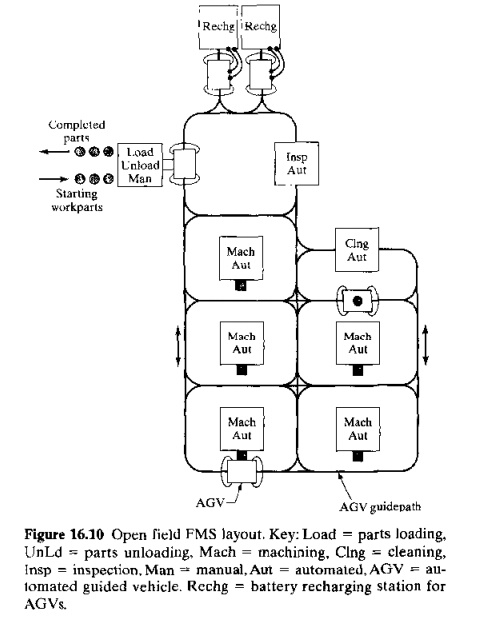

The open field layout consists of multiple

loops and ladders and may include sidings as well. as illustrated in Figure

16.m This layout type is generally appropriate for processing a large family of

parts. The number of different machine types may be limited, and parts are

routed to different workstations depending on which one becomes available

first.

The robot-centered cell (Figure 16.1) uses

one or more robots as the material handling system. Industrial robots can be

equipped with grippers that make them well suited for the handling of

rotational parts, and robot centered FMS layouts are often used to process

cylindrical or disk shaped parts

Computer

Control System

The FMS

includes a distributed computer system that is interfaced to the workstations,

material handling system, and other hardware components. A typical FMS computer

system consists of a central computer and microcomputers controlling the

individual machines and other components. The central computer coordinates the

activities of the components to achieve smooth overall operation of the system.

Functions performed by the FMS computer control system can be grouped into the

following categories:

Workstation

control. In a fully automated FMS, the individual processing or assembly stations

generally operate under some form of computer control. For a machining system,

CNC is used to control the individual machine tools.

Distribution of control instructions to

workstations. Some form of central intelligence is also required

to coordinate the processing at individual stations. In a machining FMS, part

programs must be downloaded to machines, and DNC is used for this purpose, The

DNC system stores the programs, allows submission of new programs and editing

of existing programs as needed, and performs other DNC functions (Section 6.3).

Production

control. The part mix and rate at which the various parts are launched into the system must be managed. Input data

required for production control includes desired daily production rates per

part. numbers of raw work-parts available, and number of applicable pallets.'

The production control function is accomplished by routing an applicable pallet

10 the load/unload area and providing instructions to the operator for loading

the desired work-part.

Traffic

control. This refers to the management of the primary material handling system

that moves workparts between stations. Traffic control is accomplished by

actuating switches at branches and merging points. stopping parts at machine

tool transfer locations, and moving pallets to load/unload stations.

Shuttle

control. This control function is concerned with the operation and control of the secondary handling system at each

workstation. Each shuttle must be coordinated with the primary handling system

and synchronized with the operation of the machine tool it serves,

Work-piece

monitoring. The

computer must monitor the status of each cart and/or pallet in the primary and secondary handling systems as well as

the status of each of the various workpiece types.

Tool

control. In a machining system, cutting tools are required. Tool control is

concerned with managing two aspects of the cutting tools:

Tool location. This involves keeping track of

the cutting tools at each workstation, If one or mere tools required to process

a particular workpiece is not present at the station that is specified in the

part's routing, the tool control subsystem takes one or both of the following

actions: (a) determines whether an alternative workstation that has the

required tool is available and/or (b) notifies the opera tor responsible for

tooling in the system that the tool storage unit at the station must be loaded

with the required cutter(s).

Tool life monitoring. 1.nthis

aspect of tool control, a tool life isspecif.ied to the computer for each cutting tool in the FMS. A record of the

machining time usage i••maintained for each of the tools, and when the

cumulative machining time reaches the specified life of the tool, the operator

is notified that a tool replacement is needed.

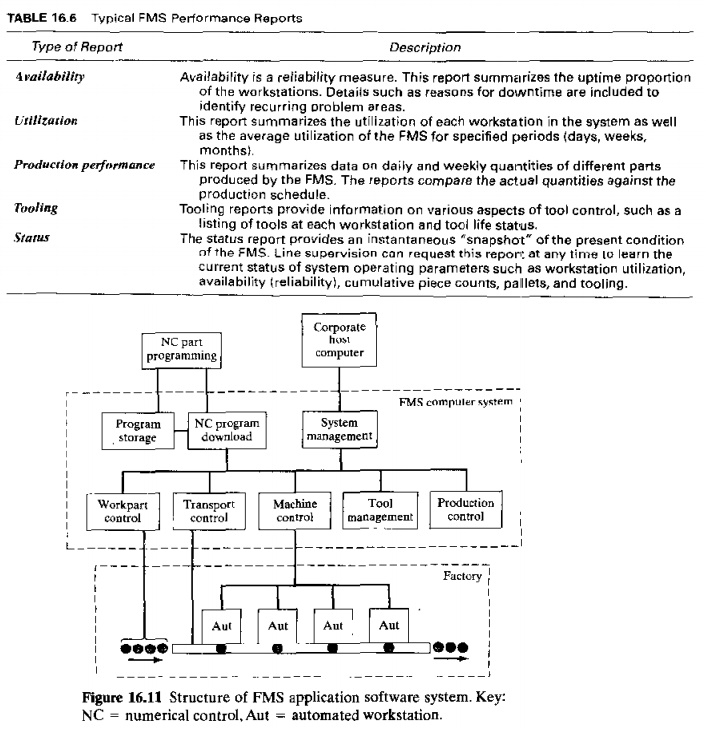

K Performance monitoring and reporting.

The computer control system is programmed

to collect data on the operation and performance of the FMS. This data is

periodically summarized, and reports are prepared for management on system

performance. Some of the important reports that indicate FMS performance are

listed in Table 16.6

Diagnostics. This function is available to a

greater or lesser degree on many manufacturing systems to indicate the probable

source of the problem when a malfunction occurs. It can also be used to plan

preventive maintenance iu the system and to identify Impending failures. The

purpose of the diagnostics function is to reduce breakdowns and downtime and

increase availability of the system.

The

modular structure of the FMS application software for system control is

illustrated in Figure 16.11. It should be noted that an FMS possesses the characteristic

architecture or a DNC system. As in other DNC systems. Two-way communication is

used. Data and commands an: sent from the central computer to the individual

machines and other hardware components, and data on execution and performance

are transmitted from the components hack up to the central computer. In

addition, an uplink from the FMS to the corporate host computer is provided

Human Resources

One

additional component in the FMS is human labor. Humans are needed to manage the

operations of the FMS. Functions typically performed by humans include: (1) loading raw

workparts into the system, (2) unloading finished parts (or assemblies) from

the system.

(3)

changing and setting tools. (4) equipment maintenance and repair, (5) NC part

programming in a machining system, (6) programming and operating the computer

system, and (7) overall management of the system

Related Topics