Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Flexible Manufacturing Systems

Flexible Manufacturing Systems(FMS) Applications and Benefits

FMS APPLICATIONS

AND BENEFITS

In this

section, we explore the applications of FMSs and the benefits that result from

these applications. Many of the findings from the industrial survey on cellular

manufacturing (reported in Section 15.5.2) are pertinent to FMSs, and we refer

the reader to that report .

FMS Applications

The

concept of flexible automation is applicable to a variety of manufacturing

operations. In this section, some of

the important FMS applications are reviewed. FMS technology i~ most widely applied in machining

operations. Other applications include sheet metal pressworking, forging, and

assembly. Here some of the applications are examined using case study examples

to illustrate.

Flexible

Machining Systems. Historically. most of the applications of flexible

machining systems have been in milling and drilling type operations (non rotational

parts), using NC and subsequently CNC machining centers. FMS applications for

turning (rotational parts) were much less common until recently, and the

systems that are installed tend to consist of fewer machines. For example,

single machine cells consisting of parts storage units, part loading robots,

and CNC turning centers are widely used today, although not always in a

flexible mode. Let us explore some of the issues behind this anomaly in the

development of flexible machining systems.

By

contrast with rotational parts, nonrotational parts are often too heavy for a

human operator to easily and quickly load into the machine tool. Accordingly,

pallet fixtures were developed so that these parts could be loaded onto the pallet

offline and then the part on. pallet could be moved into position in front of

the machine tool spindle. Non rotational pans also tend to be more expensive

than rotational parts, and the manufacturing lead times tend to be longer.

These factors provide a strong incentive to produce them as efficiently as

possible, using advanced technologies such as FMSs. For these reasons, the

technology for FMS milling and drilling applications is more mature today than

for FMS turning applications

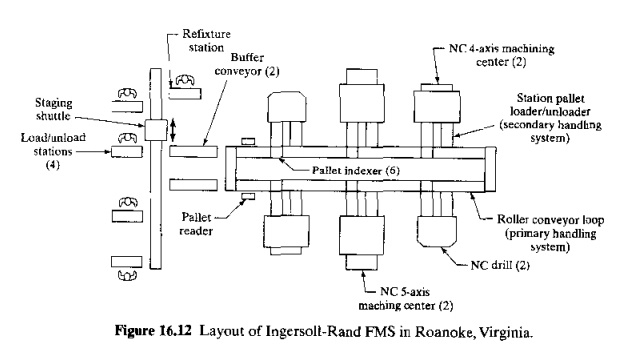

EXAMPLE 16.1 FMS

at Ingersoll-Rand in Roanoke, Virginia

One of

the first FMS installations in the United States was at the Roanoke, Virginia. plant

of the Tool and Hoist Division of Ingersoll-Rand Corp. The system was installed

by Sundstrand in the late 1960& It consists of two five-axis machining

centers, two four axis machining centers, and two four-axis drilling machines.

The machines are each equipped with 6Otool storage drums and automatic 1001

changers and pallet changers. A powered roller conveyor system is used for the

primary and secondary workpart handling systems. Three operators plus one

foreman run the system three shifts. Up to 140 part numbers are machined on the

system. The parts begin as cast iron and aluminum castings and are machined

into motor cases, hoist casings, and so on. Part size capability ranges up to a

0.9 m cube (36.0 in). Production quantities for the various part numbers range

from 12 per year to 20,000 per year. The layout of the system is presented in

Figure 16.12.

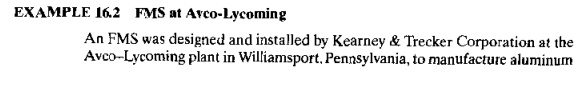

crankcase

halves for aircraft engines. The layout is an open field type and is

illustrated in Figure 16.13. The handling of work-parts between machines is

performed by an in-floor

towline cart system with a total of 2~ pallet carts. The system contains 14 machine

tools: one duplex multispindle bead indexer, two simplex multi-spindle head

indexers, and 11 machining centers. In a multispindie head indexer, machining

heads are attached to an indexing mechanism that indexes (rotates in specified

angular amounts) to bring the correct machining head into position to address

the work. A simplex unit processes the work on one side only, while a duplex

has two indexers on opposite sides of the work. Machining centers are described

in Section 14.3.3.

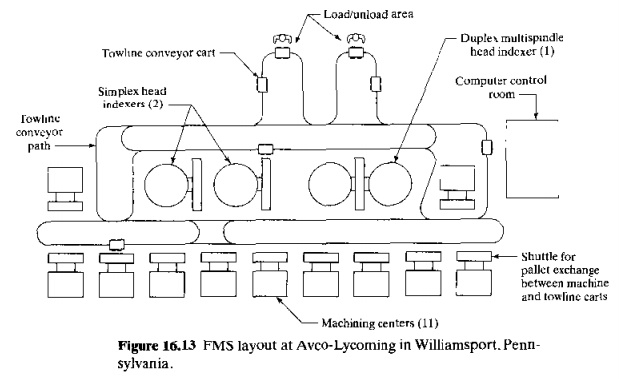

EXAMPLE 16.3 Vought Aerospace FMS

An FMS

installed at Vought Aerospace in Dallas. Texas, by Cincinnati Milacron is shown

in Figure 16.14. The system is used to machine approximately 600 different

aircraft components. The FMS consists of eight CNC horizontal machining centers

plus inspection modules. Part handling is accomplished by an automated guided

vehicle system using four vehicles. Loading and unloading of the system is done

at two stations. These load/unload stations consist of storage carousels that

permit parts to be stored on pallets for subsequent transfer to the machining

stations by the AGVS. The system is capable of processing a sequence of single,

one-of-a-kind parts in a continuous mode. permitting a complete set of

components for one aircraft to be made efficiently without batching.

Other

FMS Applications. Pressworking and forging arc two other

manufacturing processes in which efforts are

being made to develop flexible automated systems.

The following example

illustrates the development efforts in the pressworking area.

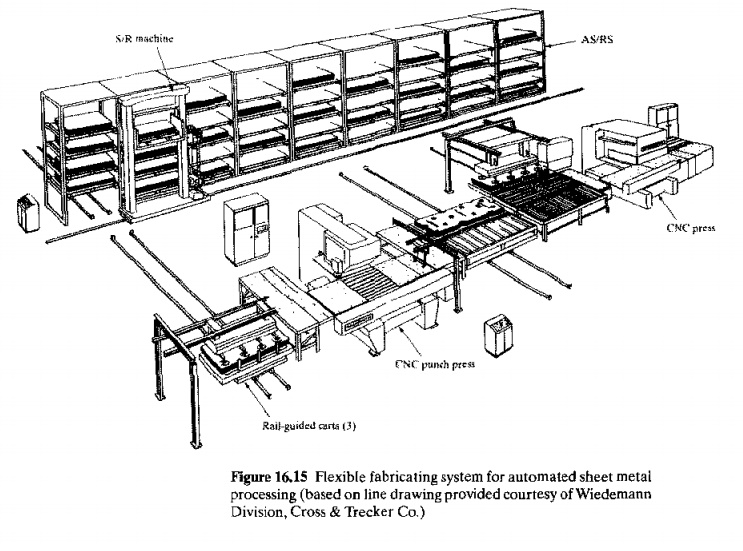

EXAMPLE 16.4 Flexible

Fabricating System

The term

flexible fabricating system (FFS) is sometimes used in connection with systems

that perform sheet metal press working operations. One FFS concept by Wiedemann

is illustrated in Figure 16,15. The system is designed to unload sheet metal

stock from the automated storage/retrieval system (AS/RS), move the stock by

rail-guided cart to the CNC punch press operations, and then move the finished

parts back to the AS/RS, all under computer control.

Flexible

automation concepts can be applied to assembly operations. Although some

examples have included industrial robots to perform the assembly tasks, the

following example illustrates a flexible assembly system that makes minimal use

of industrial robots.

EXAMPLE 16.5 Assembly FMS at Allen-Bradley

An FMS

for assembly installed by Allen-Bradley Company is reported in {421. The

"flexible automated assembly line" produces motor starters in 125

model styles. The line boasts a 1 day manufacturing lead time on Jot sizes as

low as

one and

production rates of 600 units/hr. The system consists of 26 workstations that

perform all assembly, subassembly, testing, ami packaging required to make the

product. The stations are linear and rotary indexing assembly machines with

pick-and-place robots performing certain handling functions between the

machines. 100% automated testing at each step in the process is used to achieve

very high quality levels. The flexible assembly line is controlled by a system

of Allen-Bradley programmable logic controllers.

FMS Benefits

A number

of benefits can be expected in successful FMS applications. The principal

benefits are the following:

Increased

machine utilization. FMSs achieve a higher average

utilization than machines in a conventional batch production machine shop.

Reasons for this include:

(1) 24

hr/day operation. (2) automatic tool changing ar machine tools. (3) automatic

pallet changing at workstations. (4) queues of parts at stations, and (5)

dynamic scheduling of production that takes into account irregularities from

normal operations. It should be possible to approach 80-90% asset utilization by

implementing FMS technology [23].

Fewer machines

required Because of higher machine utilization. fewer machines are required.

Reduction

in factory floor space required. Compared with a job shop of

equivalent capacity, an fMS generally

requires less floor area. Reductions in floor space requirements are estimated to he 40-50%, [23].

Greater

responsiveness to change. An FMS improves response capability to part design

changes. introduction of new part s, changes in production schedule and product

mix. machine breakdowns. and cutting tool failures. Adjustments can be made in

the production schedule from one day to the next to respond to rush orders and

special customer requests.

Reduced

inventory requirements, Because different parts are processed together rather than separately in batches. Work-in-process

(WIP) is less than in a batch production mode. The inventorv of starting and

finished parts can be reduced as well. Inventory reductions of 60-80% are

estimated.

Lower

manufacturing lead times. Closely correlated with reduced WIP is the time spent in process by the parts. This

means faster customer deliveries

Reduced

direct labor requirements and higher

labor productivity. Higher production

rates and lower reliance on direct labor translate to greater productivity

per labor hour with an FMS than with conventional production methods. Labor

savings of 30-.50%, arc estimated [23].

Opportunity

for unattended production. The high level of automation in an FMS allows it to

operate for extended periods of time without human attention. In the most

optimistic scenario, parts and tools are loaded into the system at the end of

the day shift, and the FMS continues to operate throughout the night so that

the finished parts can be unloaded the next morning.

Related Topics