Chapter: Modern Analytical Chemistry: Kinetic Methods of Analysis

Evaluation of Chemical Kinetic Methods

Evaluation of Chemical Kinetic Methods

Scale of Operation

The detection limit for chemical kinetic methods ranges

from minor components to ultratrace components and is principally determined by two factors:

the rate of the reaction

and the instrumental method used for monitoring the rate. Because

the signal is directly proportional to the reaction rate,

faster reactions generally result in lower

detection limits. All

other considerations being equal,

the detection limit

is smaller for

catalytic reactions than for noncatalytic reactions. Not surprisingly, chemical

kinetic methods based

on catalysis were among the earliest techniques for trace-level analysis. Ultratrace

analysis is also possible when using catalytic reactions. For example,

ultratrace levels of Cu (<1 ppb)

can be determined by measuring its

catalytic effect on the redox

re- action between hydroquinone and H2O2. Without

a catalyst, most chemical kinetic methods for organic compounds

involve reactions with relatively slow rates, limit- ing the method to minor and

higher concentration trace

analytes. Noncatalytic chemical kinetic methods for inorganic compounds involving

metal–ligand com- plexation may be fast or slow, with detection limits ranging from trace to minor lev- els of analyte.

The second factor

influencing detection limits

is the instru- mental method used to monitor the

reaction’s progress. Most reactions

are monitored spectrophotometrically or electro- chemically.

Accuracy

As noted earlier, chemical kinetic methods

are po- tentially subject

to larger errors

than equilibrium methods

due to the effect of uncontrolled or poorly controlled

variables, such as temperature and solution

pH. Although the direct-

computation chemical kinetic methods described can

yield results with

moderate accuracy (1–5%),

re- action systems

are encountered in which accuracy is quite

poor. An improvement in accuracy may be realized

by using curve-fitting methods. In one

study, for

example, accuracy was improved by two orders

of magnitude (500–5%) by replacing a direct-computation analysis with a curve-fitting analysis.

Although not discussed in this, data analy- sis

methods that include

the ability to compensate for

experi- mental error can lead to a significant improvement in accuracy.

Precision

The precision of a chemical

kinetic method is lim-

ited by the signal-to-noise ratio of the instrumental method used to monitor the reaction’s progress.

With integral methods, precisions of 1–2% are routinely possible. The precision for dif-

ferential methods may be somewhat

poorer, particularly for noisy signals,

due to the difficulty in measuring the slope of a

noisy rate curve.19 It may

be possible to improve the

precision in this case by using a combination of signal averaging

and smoothing of the data before its analysis.

Sensitivity

The sensitivity for a one-point fixed-time integral method of

analysis is improved by making measurements under conditions in which the concentration of the

monitored species is larger rather

than smaller. When the analyte’s concentra- tion, or the concentration of any other reactant, is

monitored, measurements are best made early

in the reaction before its concentration has substantially decreased. On the other hand, when a product is used to monitor the reaction, measurements are more appropriately made

at longer times.

For a two-point fixed-time integral method, sensitivity is improved by increasing the

difference between times

t1 and t2. As discussed earlier, the

sensitivity of a rate method

improves when using

the initial rate.

Selectivity

The analysis

of closely related

compounds, as we have seen in earlier, is often complicated by their tendency

to interfere with one an- other. To overcome this problem, the analyte and interferent must first be sepa-

rated. An advantage of chemical kinetic methods is that conditions can often be adjusted so that the analyte and interferent have different reaction

rates. If the difference in rates is large enough,

one species may react completely before the other

species has a chance to react. For

example, many enzymes

selectively cat- alyze a single substrate, allowing the quantitative analysis of that substrate in the presence of similar substrates.

The conditions necessary to ensure that

a faster-reacting species

can be kineti- cally separated from a more slowly

reacting species can be determined from the ap- propriate integrated rate laws.

As an example, let’s consider

a system consisting of an analyte, A, and an interferent, B, both of which show

first-order kinetics with

a common reagent. To avoid an interference, the

relative magnitudes of their rate constants must be sufficiently different. The fractions, f, of A and B remaining at any point in time, t, are

given as

For a first-order reaction we can write, from equations 13.2,

13.21, and 13.22

ln(fA)t =

–kAt

ln(fB)t = –kBt

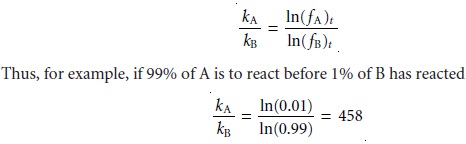

Taking the ratio of these two equations gives

then the rate constant for A must be 458 times larger

than that for B. Under

these conditions the analyte’s concentration can be determined before

the interferent be- gins

to react. If the analyte

has the slower reaction, then it can be determined after the interferent’s reaction

is complete.

The method described

here is impractical when the simultaneous analysis of both A and B is desired. The difficulty

in this case is that conditions favoring

the analysis of A generally

do not favor the

analysis of B. For

example, if condi- tions are adjusted

such that 99% of A reacts in 5 s, then B must reach 99% com- pletion

in either 0.01 s if it has the faster kinetics or 2300 s if it has the slower

kinetics.

Several additional approaches for analyzing mixtures have been developed that do not require

such a large

difference in rate

constants.3,4 Because both A and

B react at the

same time, the

integrated form of the first-order rate law becomes

Ct = [A]t + [B]t = [A]0e–kAt +

[B]0e–kBt ………………….13.23

where Ct is the total

concentration of A and B. If Ct is measured at times t1 and t2, the resulting pair of simultaneous equations can be solved to give [A]0 and [B]0.

The rate constants kA and kB must be determined in separate experiments using standard solutions of A and B. Alternatively, if A and B react

to form a common

product, P, equation 13.23 can be written

as

Pt = [A]0(1 – e–kAt) + [B]0(1 – e–kBt)

Again, a pair of simultaneous equations at times t1 and t2 can be solved

for [A]0 and [B]0.

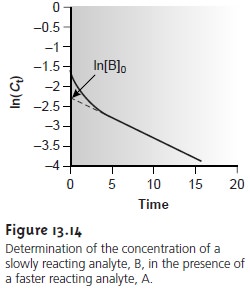

Equation 13.23 can

also be used

as the basis

for a curve-fitting method. As shown in Figure 13.14,

a plot of ln(Ct) as a function of time consists of two regions. At short times the plot is curved since

A and B are reacting

simultaneously. At later times, however, the concentration of the faster-reacting component, A, decreases to 0, and equation

13.23 simplifies to

Under these conditions a plot of ln(Ct) versus time is linear. Extrapolating the linear portion to time 0 gives [B]0, and [A]0 is determined by difference.

Time, Cost, and Equipment

Automated chemical kinetic methods of analysis provide a rapid means for analyzing samples,

with throughputs ranging

from several hundred to

several thousand determinations per hour. The initial start-up costs, however, may be fairly

high because an automated analysis

requires a dedicated in- strument designed to meet the specific needs of the analysis. When handled manu- ally, chemical kinetic methods

can be accomplished using equipment and instru-

mentation routinely available in most laboratories. Sample throughput, however,

is much lower than with automated methods.

Related Topics