Chapter: Civil : Repair and Rehabilitation of Structures : Serviceability and Durability of Concrete

Effects due to Climate, Temperature, Chemical, Corrosion on Concrete

Effects

due Climate

The lack of durability of

concrete on account of freezing and thawing action of frost is not of great

importance to Indian conditions. But it is of greatest considerations in most

part of the world.

The most severe climatic attack

on concrete occurs, when concrete containing moisture is subjected to cycle of

freezing and thawing. The capillary pores in the cement paste are of such a

size that water in them will freeze, when the ambient temperature is below

0degree C.

The gel pores are so small that

water in them does freeze at normal winter temperatures. As water, when

freezing expands by 9% of its volume, excess water in the capillaries has to

move. Since the cement paste is relatively impermeable high pressures are

necessary to move the excess water even over quite small distances. For normal

strength concrete, it has been found that movement of the order of 0.2mm is

sufficient to require pressures which approach the tensile strength of the

paste.

Concrete can

be protected from

freeze-thaw damage by

the entrainment of

the appropriate quantities of air

distributed through the cement paste, with spacing between bubbles of not more than

about 0.4mm. The air bubbles must remain partially empty, so that they can

accommodate the excess water moved to them. This will generally be the case,

since the bubbles constitute the coarsest pore system, and are therefore the

first to, most moisture as the concrete dries. Fully saturated concrete, if

permanently submerged, will not need protection against freezing, but concrete

which has been saturated and is exposed to freezing as for example in the tidal

range, may not be effectively protected by air entrainment.

For effective protection, an air

entraining agent must be added to the mix, to entrain the appropriate amount of

air, and to induce a bubble system, with an appropriate spacing. When AEA is

used, it is only the amount of air entrained which can be measured in the wet

concrete. The amount of air required is between 4-8%, depending on the maximum

size of aggregate. Air is entrained during the mixing action, even when no AEA

is added. The effect of AEA is to stabilize the air bubbles in the form

desired.

More air is entrained with a

larger dose of AEA but the effect is not linear and with most agents levels off

larger doses. For mixes with higher slump, more air is entrained. It is

difficult to entrain air is very stiff mixes; the grading and nature of the particles

in the fine aggregates have a very marked effect, on the amount of air

entrained. It has been shown that the sand is the most important single factor

in air entrainment.

It has been suggested that if

concrete can be so dense, that there are no inter-connected capillary pores,

and then resistances to freeze- thaw deterioration will exist without the need

for air entrainment.

The use of high cement content

and low w/c ratio will lead in this direction as will the introduction of

silica flume, but there is yet firm evidence to show that, it would be wise to

dispense with air-entrainment, if freeze-thaw resistance is wanted.

Effects due to temperature

Temperatures of concrete, other than special refractory

concrete, have to be kept below 300degrre

C. Heat may

affect concrete as result of:

ü The

removal of evaporable water

ü The

removable of combined water

ü Alteration

of cement paste

ü Disruption

from disparity of expansion and resulting thermal stress

ü Alteration

of aggregate

ü Change of

the bond between aggregate and paste

Effects due to Chemical

Some of the factors, which

increases the vulnerability of concrete to external chemical attack:

ü High

porosity, and hence high permeability

ü Improper

choice of cement type for the conditions of exposure

ü Inadequate

curing prior to exposure

ü Exposure

to alternate cycles of wetting and drying and to a lesser extent heating and

cooling, with allowance for the fact that higher temperature increase

reactivity

ü Increased

fluid velocities

ü Expansive

reactions of any sort which may cause cracking and any other physical

phenomena, which lead to greater exposure of reactant surfaces

ü Suction

forces

ü Unsatisfactory

choice of shape and surface to volume ratios of concrete section

Effects due to Corrosion

Corrosion is defined as the

process of deterioration (or destruction) and consequent loss of a solid

metallic material, through an unwanted (or unintentional) chemical or

electro-chemical attack by its environment, starting at its

surface, is called Corrosion. Thus corrosion is a process of 'reverse

of extraction of metals'.

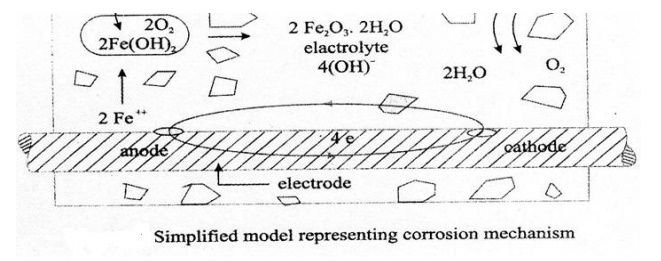

Corrosion Mechanism - Wet or

Electro-Chemical Corrosion

Corrosion of steel concrete is an

electro-chemical process. When there is a difference in electrical potential,

along the reinforcement in concrete, an electro-chemical cell is set up. In the

steel, one part becomes anode (an electrode with a +ve charge) and other part

becomes cathode, (an electrode with a -ve

charge) connected by electrolyte in the form of pore water, in the hardened

cement paste. The +vely charged ferrous ions Fe+ at the anode pass

into solution, while the -vely charged free electrons -pass

through the steel into cathode, where they are absorbed by the constituents of

the electrolyte, and combine with water and oxygen to form hydroxyl ions (OH).

These travel through the

electrolyte and combine with the ferrous ions to form ferric hydroxide, which

is converted by further oxidation to rust.

The reactions are described

below:

Anodic Reactions:

Fe - - > Fe+++ 2e-

Fe+++

2(OH)2 - - > Fe(OH)2

Fe(OH)2.2H2O

+O2 -- > 4Fe(OH)3

Cathodic Reaction

4e- +O2+H2O -- -

> 4(OH)

It can be noted that no corrosion

takes place if the concrete is dry probably below relative humidity of 60%,

because enough water is not there to promote corrosion. it can also be noted

that corrosion does not take place, id concrete is fully immersed in water,

because diffusion of oxygen does not take place into the concrete. Probably the

optimum relative humidity for corrosion is 70-80%

The products of corrosion occupy

a volume as much as 6 times the original volume of steel, depending upon the

oxidation state. Figure below shows the increase in volume of steel, depending

upon the oxidation state.

it may be pointed out that though

the 2 reactions Fe2 and OH originate iron the anode and cathode respectively,

their combination occurs more commonly at the cathode, because the Sn. alert

Fe2+ ions diffuse more rapidly than the larger OH ions. So, corrosion occurs at

the anode, but rust is deposited at or near the cathode.

Increase the oxygen content has 2 effects:

(i)

It forces the cathode reaction to the right,

producing more OH- ions and

(ii)

It removes more electrons and therefore,

accelerates the corrosion at the anode.

Each of these effects, in turn,

supplies more reactants for the forming reaction. Obviously, presence of oxygen

greatly accelerates both corrosion and rust formation, with the corrosion

occurring the entire anode, but the rust forming at the cathode.

Related Topics