Chapter: Operations Research: An Introduction : Duality and Post-Optimal Analysis

Economic Interpretation of Duality

ECONOMIC INTERPRETATION OF DUALITY

The

linear programming problem can be viewed as a resource allocation model in

which the objective is to maximize revenue subject to the availability of

limited re-sources. Looking at the problem from this standpoint, the associated

dual problem of-fers interesting economic interpretations of the LP resource

allocation model.

To

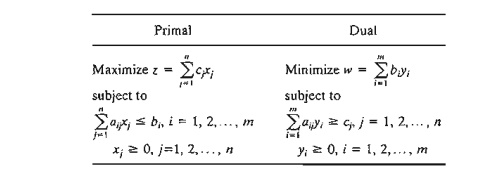

formalize the discussion, we consider the following representation of the

gen-eral primal and dual problems:

Viewed as

a resource allocation model, the primal problem has n economic activities and m

resources. The coefficient Cj in the primal represents the

revenue per unit ofactivity j. Resource i, whose

maximum availability is bi , is

consumed at the rate aij units per unit of activity j.

1. Economic Interpretation of Dual Variables

Section

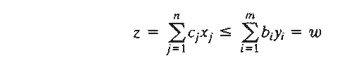

4.2.3 states that for any two primal and dual feasible solutions, the values of the objective functions, when

finite, must satisfy the following inequality:

The

strict equality, z = w, holds when both the primal and

dual solutions are optimal. Let us consider the optimal condition z = w first. Given that the primal problem

represents a resource allocation model, we can think of z as representing revenue dollars. Because bi

represents the number of units available of resource i, the

equation

z = w can be

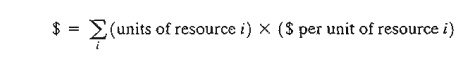

expressed dimensionally as

This

means that the dual variable, yi represents the worth per unit of resource i. As

stated in Section 3.6, the standard name dual

(or shadow) price of resource i replaces

the name worth per unit in all LP

literature and software packages.

Using the

same logic, the inequality z < w associated with any two feasible

pri-mal and dual solutions is interpreted as

(Revenue)

< (Worth of resources)

This

relationship says that so long as the total revenue from all the activities is

less than the worth of the resources, the corresponding primal and dual

solutions are not opti-mal. Optimality (maximum revenue) is reached only when

the resources have been ex-ploited completely, which can happen only when the

input (worth of the resources) equals the output (revenue dollars). In economic

terms, the system is said to be unstable (nonoptimal)

when the input (worth of the resources) exceeds the output (revenue). Stability occurs only when the two quantities are

equal.

Example

4.3-1

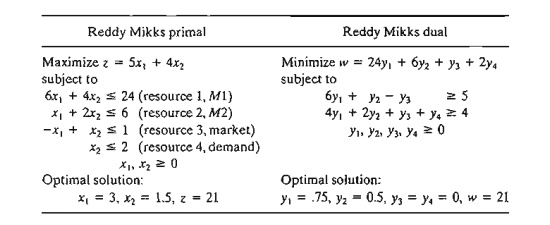

The Reddy

Mikks model (Example 2.1-1) and its dual are given as:

Briefly,

the Reddy Mikks model deals with the production of two types of paint (interior

and exterior) using two raw materials Ml and M2 (resources 1 and 2) and subject to market and demand limits

represented by the third and fourth constraints. The model determines the

amounts (in tons/day) of interior and exterior paints that maximize the daily

revenue (expressed in thousands of dollars).

The

optimal dual solution shows that the dual price (worth per unit) of raw

material Ml (re-source 1) is yl = .75 (or

$750 per ton), and that of raw material M2

(resource 2) is y2 = .5 (or

$500 per ton). These results hold true for specific feasibility ranges as we showed in Section 3.6. For resources 3 and

4, representing the market and demand limits, the dual prices are both zero,

which indicates that their associated resources are abundant. Hence, their

worth per unit is zero.

PROBLEM SET 4.3A

1. In

Example 4.3-1, compute the change in the optimal revenue in each of the

following cases (use TORA output to obtain the feasibility ranges):

a. The

constraint for raw material M1 (resource 1) is 6xl + 4x2 ≤ 22.

b. The

constraint for raw material M2

(resource 2) is x1

+ 2x2 ≤ 4.5.

c. The

market condition represented by resource 4 is x2 ≤ 10.

*2. NWAC

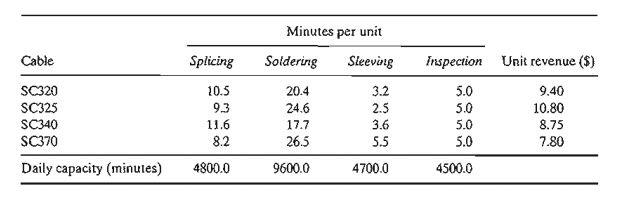

Electronics manufactures four types of simple cables for a defense contractor. Each cable

must go through four sequential operations: splicing, soldering, sleeving, and

inspection. The following table gives the pertinent data of the situation.

The

contractor guarantees a minimum production level of 100 units for each of the

four cables.

a. Formulate

the problem as a linear programming model, and determine the optimum production

schedule.

b. Based on

the dual prices, do you recommend making increases in the daily capacities of

any of the four operations? Explain.

c. Does the

minimum production requirements for the four cables represent an advan-tage or

a disadvantage for NWAC Electronics? Provide an explanation based on the dual

prices.

d. Can the

present unit contribution to revenue as specified by the dual price be

guar-anteed if we increase the capacity of soldering by 1O%?

3. BagCo

produces leather jackets and handbags. A jacket requires 8 m2 of

leather, and a handbag only 2 m2• The labor requirements for the two

products are 12 and 5 hours, re-spectively. The current weekly supplies of

leather and labor are limited to 1200 m2 and 1850 hours. The company

sells the jackets and handbags at $350 and $120, respectively. The objective is

to determine the production schedule that maximizes the net revenue. BagCo is

considering an expansion of production. What is the maximum purchase price The

company should pay for additional leather? For additional labor?

2. Economic Interpretation of Dual Constraints

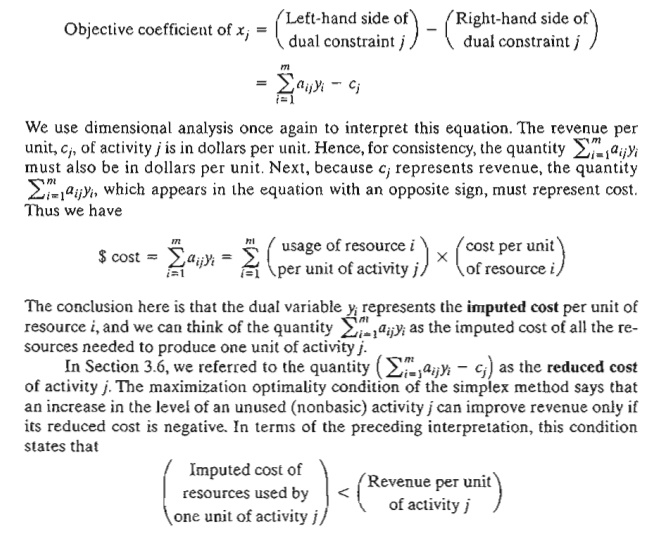

The dual

constraints can be interpreted by using Formula 2 in Section 4.2.4, which

states that at any primal iteration,

The

maximization optimality condition thus says that it is economically advantageous

to increase an activity to a positive level if its unit revenue exceeds its

unit imputed cost.

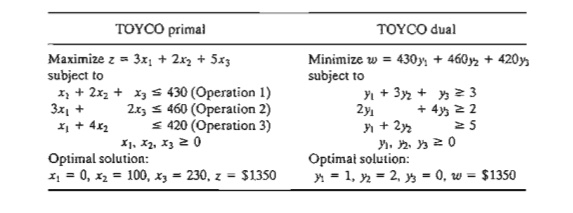

We will

use the TOYCO model of Section 3.6 to demonstrate the computation. The details

of the model are restated here for convenience.

Example

4.3-2

TOYCO

assembles three types of toys: trains, trucks, and cars using three operations.

Available assembly times for the three operations are 430,460, and 420 minutes

per day, respectively, and the revenues per toy train, truck, and car are $3,

$2, and $5, respectively. The assembly times per train for the three operations

are 1,3, and 1 minutes, respectively. The corresponding times per truck and per

car are (2,0,4) and (1,2,0) minutes (a zero time indicates that the operation

is not used).

Letting x1,x2,and x3 represent the daily number of units assembled of

trains, trucks and cars, the associated LP model and its dual are given as:

The

optimal primal solution calls for producing no toy trains, 100 toy trucks, and 230 toy cars. Suppose that TOYCO is

interested in producing toy trains as well. How can this be achieved? Looking

at the problem from the standpoint of the interpretation of the reduced cost for xl> toy trains will become

attractive economically only if the imputed cost of the resources used to

produce one toy train is strictly less than its unit revenue. TOYCO thus can

either in-crease the unit revenue per unit by raising the unit price, or it can

decrease the imputed cost of the used resources (= y1 + 3y2

+ y3). An increase in

unit price may not be possible because of market competition. A decrease in the

unit imputed cost is more plausible because it entails making improvements in

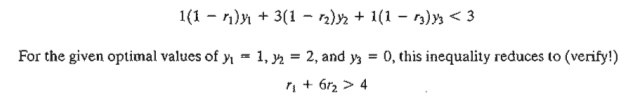

the assembly operations. Letting r1, r2, and r3 represent the propor-tions by which the unit times of

the three operations are reduced, the problem requires deter-mining r1, r2, and r3 such that the new imputed cost per

per toy train is less than its unit revenue-that is,

Thus, any

values of r1 and r2

between 0 and 1 that satisfy r1 + 6r2 > 4 should make toy trains

profitable. However, this goal may not be achievable because it requires

practically impossible reductions in the times of operations 1 and 2. For

example, even reductions as high as 50% in these times (that is, rl = r2 = .5) fail to satisfy the given condition. Thus,

TOYCO should not produce toy trains unless an increase in its unit price is

possible.

PROBLEM

SET 4.3B

1. In

Example 4.3-2, suppose that for toy trains the per-unit time of operation 2 can

be reduced from 3 minutes to at most 1.25 minutes. By how much must the

per-unit time of operation 1 be reduced to make toy trains just profitable?

*2. In

Example 4.3-2, suppose that TOYCO is studying the possibility of introducing a

fourth toy: fire trucks. The assembly does not make use of operation 1. Its

unit assembly times on operations 2 and 3 are 1 and 3 minutes, respectively.

The revenue per unit is $4. Would you advise TOYCO to introduce the new

product?

*3.

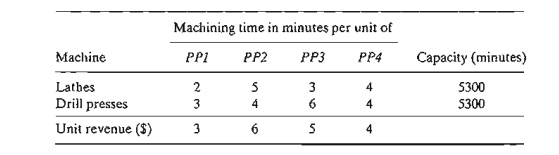

JoShop uses lathes and drill presses to produce four types of machine parts, PPl, PP2, PP3, and PP4. The table

below summarizes the pertinent data.

For the

parts that are not produced by the present optimum solution, determine the rate

of deterioration in the optimum revenue per unit increase of each of these

products.

4.

Consider the optimal solution of JoShop in Problem 3. The company estimates

that for each part that is not produced (per the optimum solution), an

across-the-board 20% re. duction in machining time can be realized through process

improvements. Would these improvements make these parts profitable? If not, what is the minimum

percentage re-duction needed to realize revenueability?

Related Topics