Chapter: Aquaculture Engineering : Recirculationand Water Re-use Systems

Design of a re-use system in Aquaculture

Design of a re-use system

A re-use plant

may be established either with continuous addition of new water or batch

exchange; the former is most common because it maintains stable water quality.

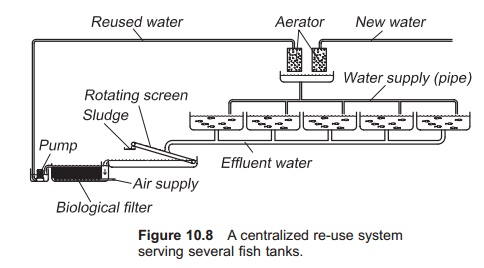

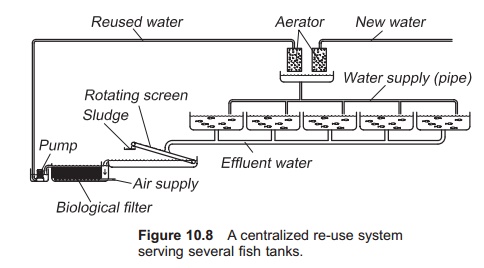

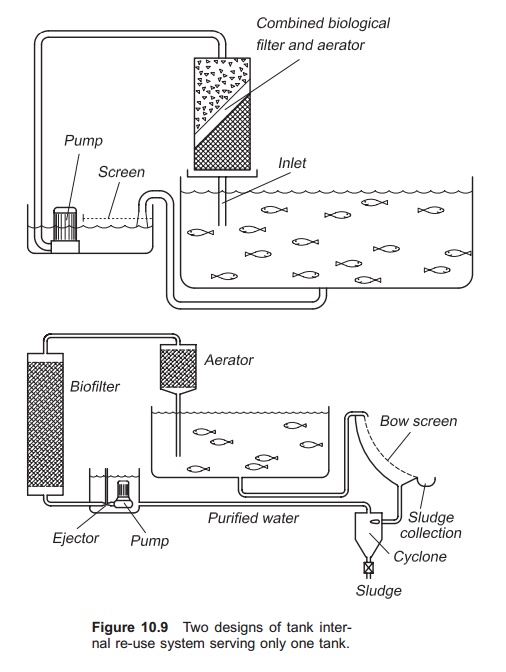

Two different

principles are used for construction of re-use plants (Figs. 10.8 and 10.9)

regardless of whether there is continuous or batch exchange of water:

· Centralized

re-use system for handling water from several fish tanks

· Re-use system

placed in a single fish tank, also known as a tank internal re-use system.

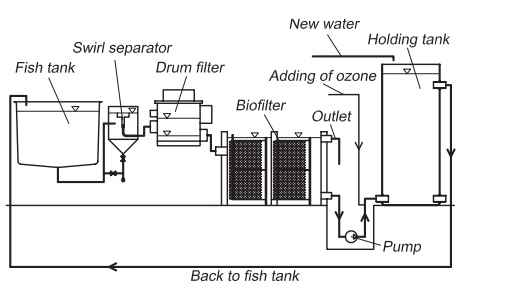

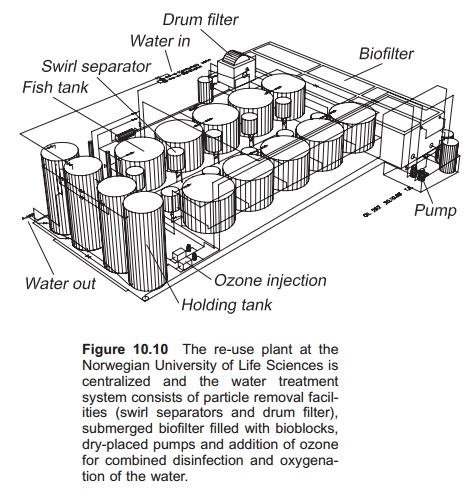

Most current

re-use systems are based on the centralized principle. Outlet water from all

the fish tanks is colleted in a common pipeline that leads directly to one

centrally placed water treatment system which includes all the necessary water

treatment components. After treatment the water is returned to the tanks via a

common inlet pipe (Fig. 10.10). Addition of the new water and removal of old

water is also performed here, either on a continuous or batch basis.

The advantage

of a centralized system is that more investment can be put in the water

treatment components because they handle more tanks and greater weight of fish.

However, one disadvantage with this system is that if infection occurs in one

tank it will be transferred via the water to all other tanks in the re-use circuit,

although this can be eliminated or reduced by installing a disinfection plant

in the circuit. Another disadvantage with a centralized water treatment system

is that it is more difficult to gradually increase the size of the farm/system.

In a single tank re-use system, the outlet water from the tank is lead directly into a water treatment system before it is returned to the same tank. Thus every tank has its own water treatment system and there is no mixing of water from different tanks. The water treatment system can either be an integral part of the fish tank, partly inside the tank volume, or it can be a separate external unit attached to the fish tank. Great flexibility is the major advantage with this system. It is easier successively to expand a fish farm. In addition, there are possibilities for better adaptation to individual loads, meaning that the degree of re-use can vary from tank to tank, and the single systems can in this way be operated optimally. The risk of spread-ing pathogens between tanks is also eliminated because there is no water connection between the tanks.

The

disadvantage is, however, the price, which inhibits development of the model.

Each tank needs a separate water treatment system; this only allows use of low

cost simple systems, but even then it is difficult to compete with centralized

systems. The management cost of such systems is also increased because there

are several units that have to be maintained and controlled; for this a larger

monitoring system is needed. Such systems are not favoured when having high

fish densities or very high percentage of re-use (>99.5%) because

this normally includes several high cost steps, such as pH regulation,

denitrification and disinfection. What is generally important when constructing

a water re-use plant is that the components are compatible with each other and

of the correct size.

In addition to

the water treatment components, it is necessary to establish a water flow in

the re-use circuit; this is done by some kind of pump. Types used include

airlift pumps, propeller pumps or centrifugal pumps. When using airlift pumps it

is possible to combine aeration with the transport of water and by this

eliminate the need for traditional pumps. In tank internal systems with a low

degree of re-use this might be done to create a low cost system. In larger

systems, traditional centrifugal pumps are most commonly used, because system

efficiency is increased. The pump is either dry-placed or submerged. When using

submerged pumps some heat will be transferred to the water from the pump,

because the pump creates heat when running; when having a high degree of re-use

this can contribute an important part of the total heating needs of warm-water

species. In addition, the fish in the system will create heat from their

metabolism, so the amount of heat that must be added is reduced even more.

Related Topics